Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Our company is well received by customers with perfect solutions, good product quality, performance, and after-sales

Advanced tumble belt shot blasting machines represent the pinnacle of surface treatment technology, integrating intelligent systems, modular designs, and sustainable innovations to address the most demanding industrial challenges. These machines go beyond traditional blasting capabilities, offering precision control, predictive maintenance, and adaptive processing that align with Industry 4.0 standards. Unlike conventional models, advanced systems leverage data analytics, robotic integration, and eco-friendly technologies to optimize performance while minimizing environmental impact.

Tumble belt shot blasting machines have evolved into a diverse range of configurations, each tailored to specific industrial needs, workpiece characteristics, and surface treatment requirements. The classification of these machines is based on a combination of design features, operational principles, automation levels, and application scope. From compact benchtop units for small parts to massive industrial systems for heavy castings, the variety of types reflects the versatility of tumble blasting technology.

Chinese manufacturers have been at the forefront of developing this diversity, leveraging modular designs and innovative engineering to create machines that cater to global market demands. Understanding the different types is essential for selecting the optimal solution, as each type offers unique advantages in terms of throughput, precision, energy efficiency, and cost-effectiveness.

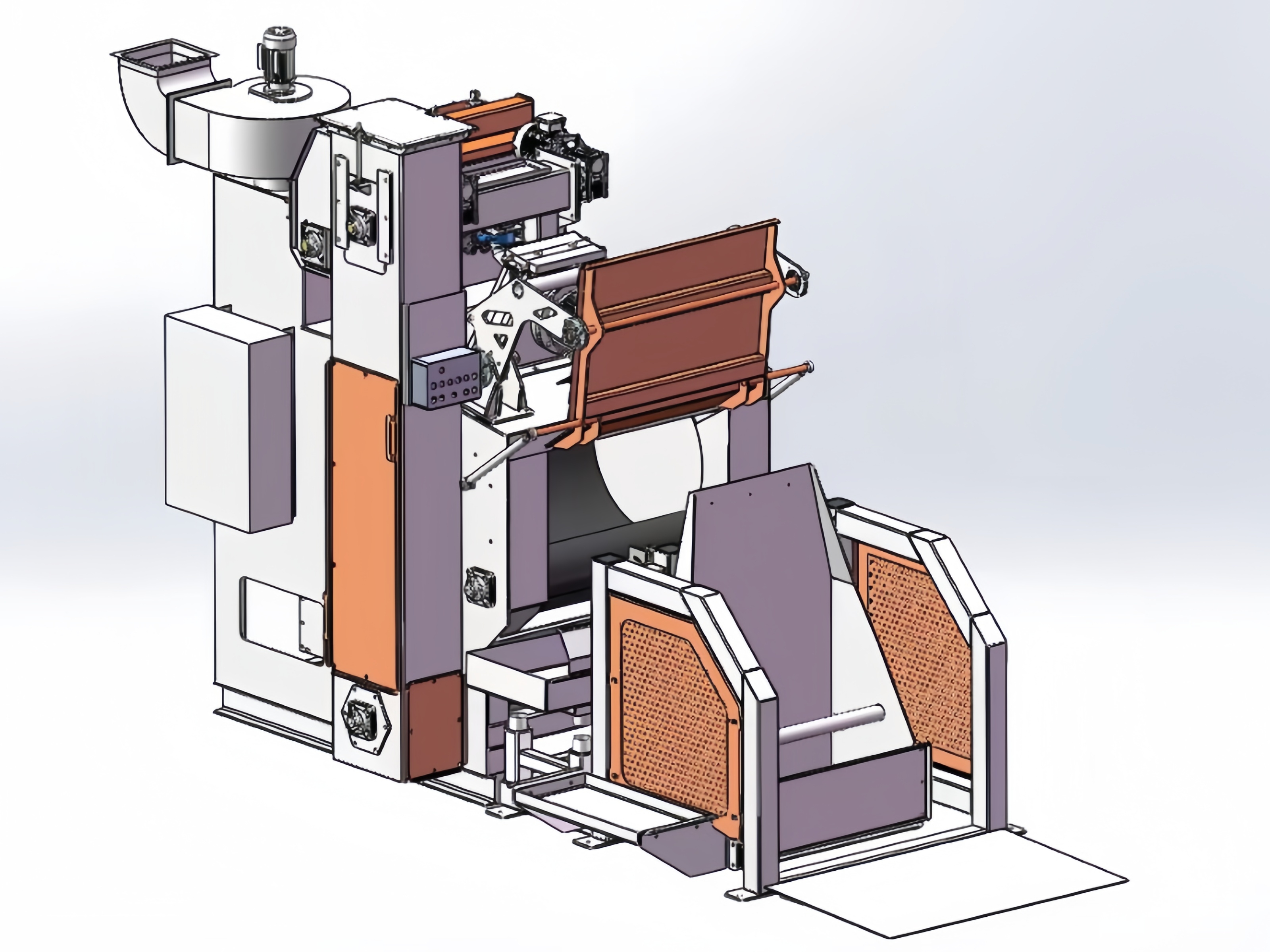

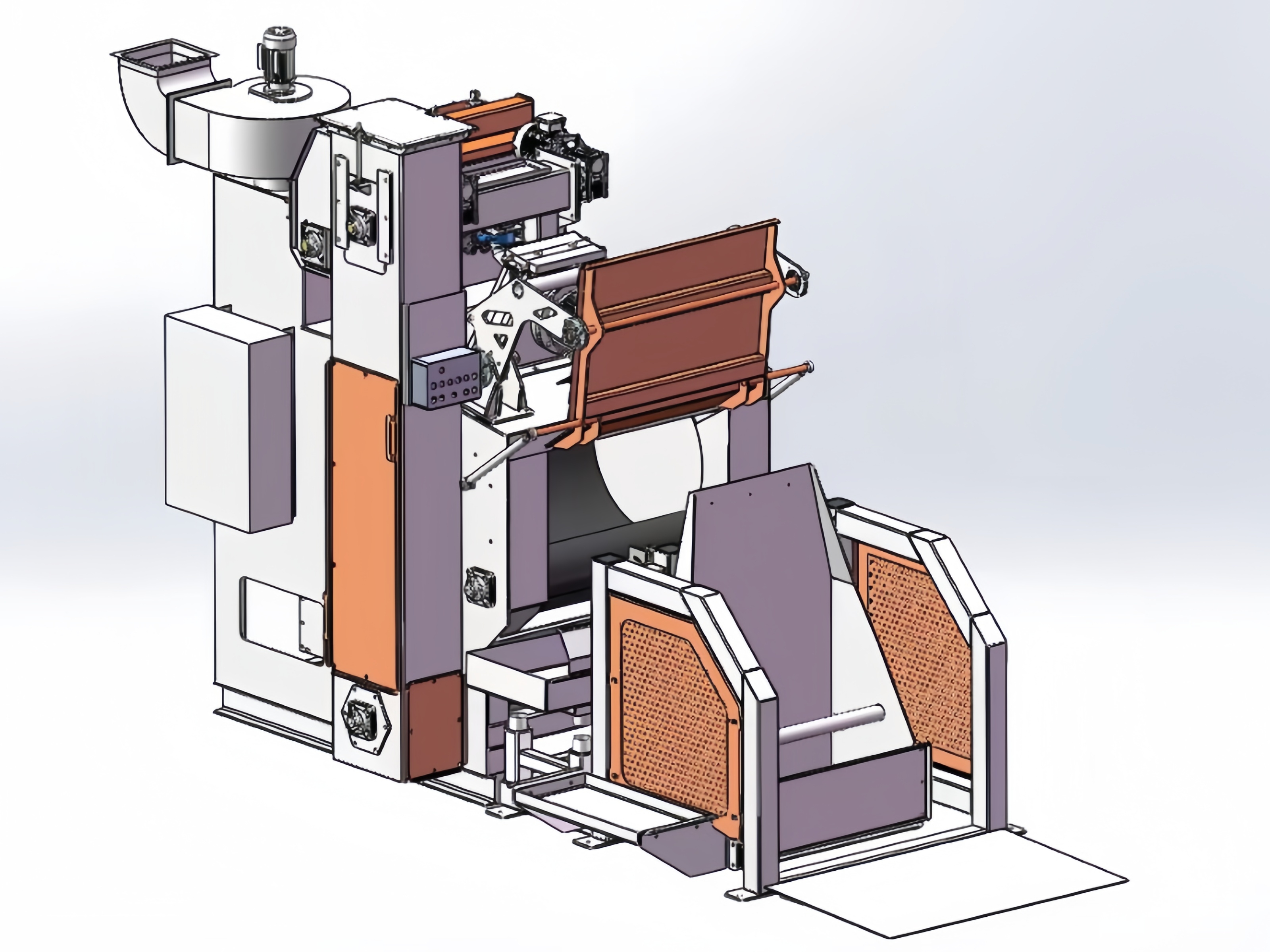

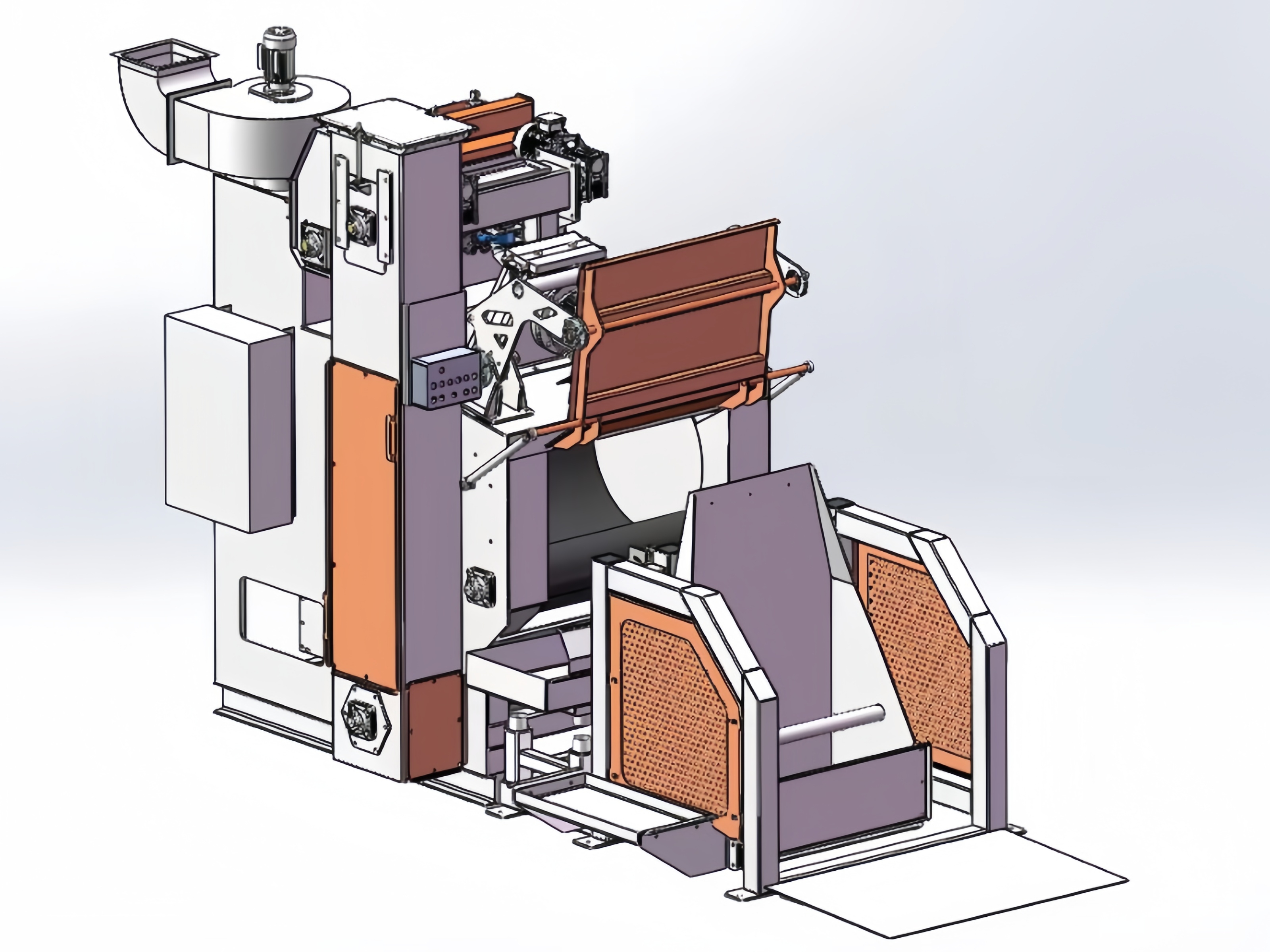

A tumble belt shot blasting machine is a specialized industrial apparatus designed to clean, strengthen, or finish the surfaces of workpieces by propelling abrasive media at high velocity. The term "tumble belt" refers to its unique conveyor system—a continuous belt that both transports parts through a blasting chamber and induces a gentle tumbling motion, ensuring all surface areas are uniformly exposed to the abrasive stream. This design merges the efficiency of automated conveying with the thoroughness of dynamic part movement, making it ideal for batch processing of small to medium-sized components.

The steel-belt tumble belt shot blasting machine represents a specialized evolution within the tumble belt series, designed to handle the most demanding surface treatment tasks for heavy-duty workpieces. Unlike traditional rubber or composite belt systems, steel-belt configurations offer unparalleled durability, load-bearing capacity, and resistance to extreme abrasion, making them indispensable for industries dealing with large, heavy, or high-temperature components.

Chinese manufacturers have pioneered the development of steel-belt technology, integrating high-strength alloy steels, advanced welding techniques, and intelligent tensioning systems to create machines that excel in harsh industrial environments. From processing massive castings in foundries to treating thick steel plates in shipbuilding, these machines redefine the limits of tumble blasting efficiency and reliability.

Rubber tumble belt shot blasting machines represent a specialized category of surface treatment equipment designed to balance efficiency, material protection, and operational versatility. Unlike traditional metal belt systems, these machines integrate rubber belts as the primary conveying mechanism, offering distinct advantages for processing delicate, non-ferrous, or surface-sensitive workpieces. The core design philosophy revolves around leveraging the elastic properties of rubber to minimize workpiece damage while maintaining rigorous blasting performance.

The tumble belt shot blasting machine series represents a diversified range of industrial solutions designed to address varying surface treatment needs across sectors. Unlike singular models, these series integrate modular designs, scalable capacities, and customizable features to cater to small job shops, medium-scale manufacturers, and large industrial plants. Chinese manufacturers lead the development of these series, offering models that balance cost-effectiveness with technological innovation—from basic manual-loading systems to fully automated intelligent machines.

This series classification is typically based on throughput capacity, workpiece size compatibility, automation level, and specialized functionalities. Whether for deburring castings, shot peening aerospace components, or preparing surfaces for coating, the tumble belt series provides tailored solutions. Understanding the nuances between series models is crucial for selecting the optimal machine to maximize productivity and surface treatment quality.

Tumble belt shot blasting machines are indispensable workhorses in the realm of surface treatment technology. They have revolutionized the way industries approach the cleaning, finishing, and strengthening of various metal and non metal components. These machines operate on a fundamental principle that involves the high velocity projection of abrasive media onto the surface of workpieces to achieve specific surface modification objectives.

At its core, a tumble belt shot blasting machine consists of several key components that work in harmony. The tumble belt, which is often made of durable materials such as high strength rubber or metal reinforced polymers, serves as the conveyor system that transports the workpieces through the blasting chamber. This belt is designed to move continuously, ensuring that each part is exposed to the abrasive stream for an appropriate duration. The blasting chamber, a robust enclosure, houses the blast wheels or impellers. These blast wheels are the heart of the machine, as they accelerate the abrasive media to high speeds using centrifugal force. The abrasive, which can range from steel shots, grits, or other specialized media, then impacts the workpiece surface with great force, effectively removing contaminants and altering the surface properties.

The versatility of tumble belt shot blasting machines is evident in their wide range of applications. In the automotive industry, they are used to clean and strengthen engine components, chassis parts, and wheels. In the aerospace sector, these machines play a crucial role in preparing aircraft parts for assembly by removing surface imperfections and enhancing fatigue resistance. Additionally, in the foundry and forging industries, tumble belt shot blasting machines are essential for post production cleaning, removing sand, scale, and other residues from cast and forged parts.

The advent of automatic tumble belt shot blasting machines marks a pivotal shift in industrial surface treatment, combining the proven efficacy of shot blasting with cutting-edge automation technologies. Unlike traditional manual or semi-automatic systems, these machines integrate programmable logic controllers (PLCs), sensor networks, and robotic interfaces to enable unattended operation, precision control, and seamless integration into smart manufacturing lines.

China has emerged as a global leader in producing automatic tumble belt systems, leveraging its expertise in industrial automation and cost-effective engineering. These machines are designed to handle complex surface treatment tasks—such as descaling, deburring, shot peening, and surface finishing—with minimal human intervention, making them indispensable for industries demanding high-volume production, consistent quality, and reduced labor costs. From automotive component manufacturing to aerospace precision parts, automatic tumble belt shot blasters have redefined efficiency in surface preparation.