Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Our company is well received by customers with perfect solutions, good product quality, performance, and after-sales

RT Rotary Table Shot Blasting Machines stand at the forefront of modern surface treatment technology, offering unparalleled precision and productivity for batch processing of metal components. The "RT" designation typically denotes robust design, rotational versatility, and advanced features tailored to industrial demands. In China, a global leader in shot blasting innovation, these machines have evolved from basic cleaning tools to intelligent systems integrating automation, energy efficiency, and data-driven controls.

At their core, RT rotary table machines utilize a rotating platform to expose workpieces to high-velocity abrasive media, removing rust, scale, and contaminants while enhancing surface properties. This configuration is ideal for complex geometries, ensuring 360° uniform treatment. Chinese manufacturers have refined RT models to address challenges in automotive, aerospace, casting, and general manufacturing, combining cost-effectiveness with cutting-edge technology to meet global quality standards.

Rotary table shot blasting machines are specialized industrial equipment designed to clean, descale, and enhance the surface quality of various components by propelling high-velocity abrasive media. These machines are widely used in sectors such as automotive, aerospace, foundry, and general manufacturing. The defining feature of a rotary table shot blasting machine is its circular rotating platform, or table, which holds the workpieces during the blasting process. This design allows for efficient and uniform treatment of multiple parts simultaneously, making it ideal for batch processing.

The basic working principle of a rotary table shot blasting machine involves the acceleration of abrasive particles, such as steel shots or grits, by turbines or impellers. These high-speed abrasives impact the surface of the workpieces placed on the rotating table, removing contaminants like rust, paint, scale, and other surface imperfections. The continuous rotation of the table ensures that each part is evenly exposed to the abrasive stream, resulting in a consistent surface finish.

In the realm of surface treatment for metal components, the rotary table shot blasting machine has emerged as a pivotal solution for batch processing of small to medium-sized workpieces. China, as a global manufacturing hub, has developed a sophisticated ecosystem for producing rotary table shot blasters that combine high efficiency, precision, and cost-effectiveness. These machines are designed to clean, descale, and strengthen components by propelling abrasive media at high velocity, making them indispensable in industries such as automotive, aerospace, casting, and general manufacturing.

The rotary table configuration—where workpieces are placed on a rotating platform inside a blasting chamber—offers unique advantages for uniform treatment of complex geometries. Unlike linear conveyor systems, rotary tables enable 360° exposure to abrasive particles, ensuring consistent surface finish on all sides of the workpiece. Chinese manufacturers have refined this design over decades, integrating advanced automation, energy-saving technologies, and robust construction to meet the demanding needs of global industrial clients.

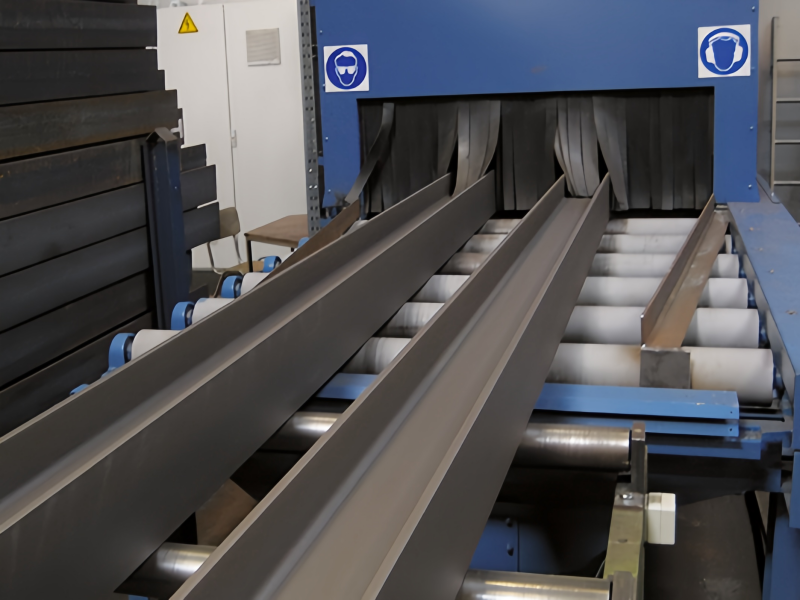

H beam shot blasting machines are specialized industrial equipment designed to clean, descale, and surface-treat H-shaped steel beams, which are widely used in construction, bridge engineering, and heavy manufacturing. These machines utilize high-velocity steel shots or abrasives to remove rust, paint, scale, and other contaminants from the surface of H beams, enhancing their durability, aesthetic appeal, and compatibility with subsequent coating or welding processes.

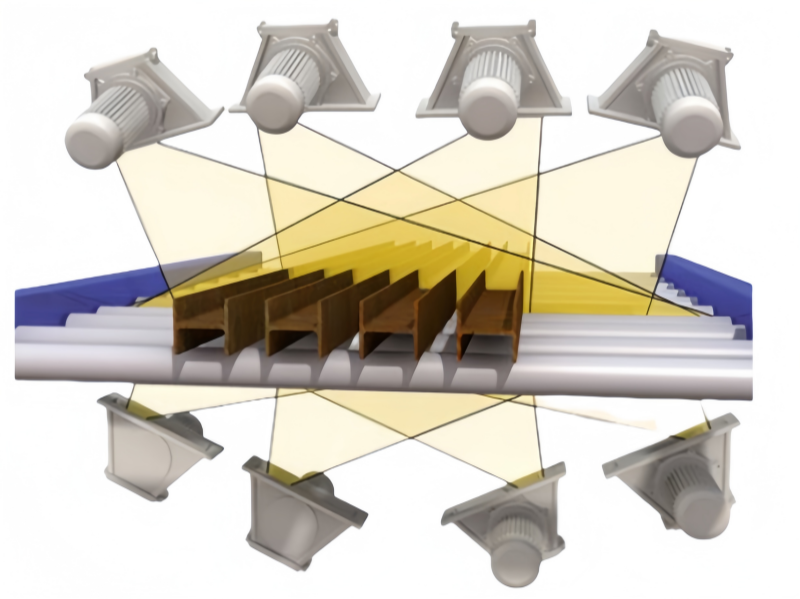

The core working principle of an H beam shot blasting machine involves a combination of mechanical propulsion and abrasive impact. High-speed impellers or turbines accelerate steel shots toward the H beam’s surface, creating a controlled impact that efficiently removes surface imperfections. The design of these machines is tailored to the unique geometry of H beams, which feature a vertical web and two horizontal flanges, requiring specialized mechanisms to ensure uniform treatment across all surfaces.

In the landscape of modern construction and heavy industry, the steel structure H beam shot blasting machine stands as a critical asset for preparing H-shaped steel beams—a fundamental component in infrastructure, bridges, buildings, and industrial equipment. As steel structures demand higher durability and corrosion resistance, the shot blasting process has evolved from a mere surface cleaning technique to a comprehensive material enhancement method.

H beams, named for their cross-sectional resemblance to the letter "H," are prized for their high strength-to-weight ratio. However, during manufacturing, their surfaces accumulate rust, mill scale, welding slag, and contaminants that compromise both aesthetics and structural integrity. Shot blasting machines address this by propelling abrasive media at high velocity to remove impurities, create a uniform surface profile, and induce beneficial compressive stresses. In China, a global hub for steel structure production, these machines have become synonymous with precision, efficiency, and technological innovation, supporting projects from skyscrapers to offshore platforms.

In the realm of metal fabrication and construction, the surface condition of H beams is of paramount importance. H beam shot blasting machines have emerged as an indispensable tool for achieving pristine and prepared surfaces. Shot blasting, as a surface treatment process, involves propelling high velocity abrasive particles onto the surface of the H beam. This mechanical action effectively removes various contaminants, including rust, mill scale, paint residues, welding slag, and other impurities.

The principle behind shot blasting is based on the kinetic energy of the abrasive particles. When these particles, which can be steel shots, grits, or other suitable abrasives, impact the surface of the H beam at high speeds, they physically dislodge and break down the unwanted materials. The impact also creates a rough, textured surface, which is highly beneficial for subsequent processes such as painting, coating, or welding. A clean and properly roughened surface ensures better adhesion of coatings and enhances the overall mechanical properties of the H beam.

The use of H beam shot blasting machines for surface cleaning has revolutionized the metalworking industry. It offers a more efficient, consistent, and environmentally friendly alternative to traditional surface cleaning methods such as manual scraping, sandblasting, or chemical cleaning. By automating the surface cleaning process, shot blasting machines can handle large volumes of H beams in a relatively short period, reducing labor costs and increasing productivity.

In the manufacturing and construction industries, surface treatment of metal components is of utmost importance. The H beam, a widely used structural steel profile, requires proper surface preparation before further processing or application. Shot blasting machines play a crucial role in achieving this. China has emerged as a leading manufacturer and exporter of H beam shot blasting machines, offering a wide range of models with advanced features and high quality performance.

Shot blasting is a process that uses high velocity abrasive particles (such as steel shots or grits) to clean, peen, or roughen the surface of a workpiece. For H beams, shot blasting is mainly used to remove rust, oxide layers, welding slag, and other contaminants from the surface. This not only improves the aesthetic appearance of the H beam but also significantly enhances its mechanical properties and corrosion resistance.

In the realm of industrial manufacturing and metal processing, the H beam shot blasting machine has emerged as a crucial piece of equipment. China, being a global powerhouse in manufacturing, has a vibrant and dynamic industry dedicated to the production of high quality H beam shot blasting machines. These machines play a pivotal role in various sectors such as construction, automotive, shipbuilding, and general manufacturing.

The primary function of an H beam shot blasting machine is to clean, prepare, and strengthen the surface of H shaped steel beams. By propelling abrasive materials at high speeds onto the surface of the H beams, these machines can effectively remove rust, scale, welding slag, and other contaminants. This not only improves the aesthetic appearance of the beams but also significantly enhances their mechanical properties and durability.