Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Our company is well received by customers with perfect solutions, good product quality, performance, and after-sales

In the intricate world of industrial manufacturing, the wire mesh shot blasting machine has emerged as a game - changing solution for wire mesh surface treatment. This specialized equipment is designed to handle the unique challenges associated with wire mesh products, offering a comprehensive range of benefits that enhance both the quality and performance of wire meshes.

In the ever - evolving world of industrial surface treatment, the tumble belt shot blasting machine has emerged as an indispensable and highly adaptable piece of equipment. This innovative machine is purpose - built to carry out a wide array of operations, spanning from meticulous cleaning and deburring to sophisticated surface strengthening, making it an integral part of countless manufacturing and processing sectors.

In the fast-paced and highly competitive industrial manufacturing domain, surface treatment stands as a linchpin in determining the quality, durability, and performance of products. Among the diverse array of surface treatment equipment, the rotary table shot blasting machine has emerged as a remarkable and highly efficient solution. This machine is engineered to offer comprehensive and precise surface treatment for a wide spectrum of workpieces, making it an indispensable asset in numerous industries.

In the dynamic landscape of industrial manufacturing, the roller conveyor shot blasting machine has emerged as a pivotal solution for surface treatment processes. This specialized equipment combines advanced technology with efficient material handling, offering a comprehensive approach to enhancing the quality and durability of a wide range of industrial products.

In the realm of industrial surface treatment, the pipe shot blasting machine stands as a crucial and versatile piece of equipment. This article will delve into its various aspects, including its introduction, applications, features, components, and basic parameters.

A pipe shot blasting machine is designed to clean, strengthen, and prepare the surfaces of pipes. It achieves this by propelling a stream of abrasive materials, such as steel shots or grits, at high velocities onto the pipe surfaces. The impact of these abrasive particles effectively removes rust, scale, paint, and other contaminants, leaving behind a clean and textured surface. This process not only improves the appearance of the pipes but also enhances their adhesion properties for subsequent coatings or treatments.

The working principle of a pipe shot blasting machine typically involves a power source, such as an electric motor or a compressed air system, which drives a mechanism to accelerate the abrasive media. The media is then directed towards the pipes through nozzles or rotating wheels, depending on the machine design. The pipes are either stationary or moved through the blasting area, ensuring that all surfaces are evenly treated.

In the advanced manufacturing sector, the hanger hook shot blasting machine has emerged as a revolutionary solution for surface treatment of large - scale and complex - shaped workpieces. By combining automated material handling with high - intensity abrasive blasting, this machine offers a perfect balance between efficiency and precision, setting new standards for industrial cleaning, deburring, and surface strengthening.

The hanger hook shot blasting machine is a specialized piece of equipment designed for continuous processing of workpiece batches. It operates on a unique overhead conveyor system where workpieces are suspended by hooks or fixtures. As the conveyor moves the workpieces through the blasting chamber, multiple high - velocity impellers project abrasive media at the workpiece surfaces. The combination of controlled rotation of the workpieces and strategically positioned blasting wheels ensures comprehensive coverage of even the most intricate geometries.

In the world of surface preparation and maintenance, the floor shot blaster has become an invaluable tool for a wide range of industries and applications. This article will provide an in - depth look at floor shot blasters, covering their introduction, applications, features, components, and basic parameters.

A floor shot blaster is a specialized piece of equipment designed to clean, prepare, and treat various types of floors. It operates on the principle of using high - velocity abrasive media, such as steel shots or grits, to impact the floor surface. This impact effectively removes contaminants like dirt, grease, paint, rust, and old coatings. The process not only restores the floor's appearance but also improves its adhesion properties for subsequent treatments like painting, coating, or tiling.

The working mechanism typically involves a power source, which can be an electric motor, a gasoline engine, or a diesel engine. This power source drives a mechanism that accelerates the abrasive media. The media is then directed onto the floor surface through nozzles or rotating wheels. As the machine moves across the floor, the abrasive particles continuously strike the surface, achieving a uniform and thorough cleaning and preparation.

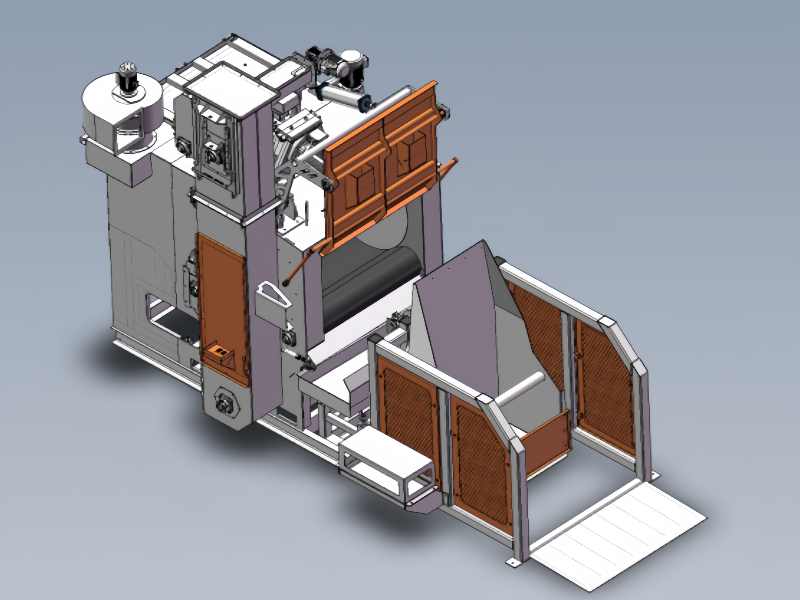

In the dynamic landscape of industrial surface treatment, one size does not fit all. This is where custom - design shot blasting machines come into play. These machines are engineered to meet the specific requirements of various industries, offering a highly personalized approach to surface cleaning, preparation, and finishing. This article will provide an in - depth exploration of custom - design shot blasting machines, covering their introduction, applications, features, components, and basic parameters.