Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Our company is well received by customers with perfect solutions, good product quality, performance, and after-sales

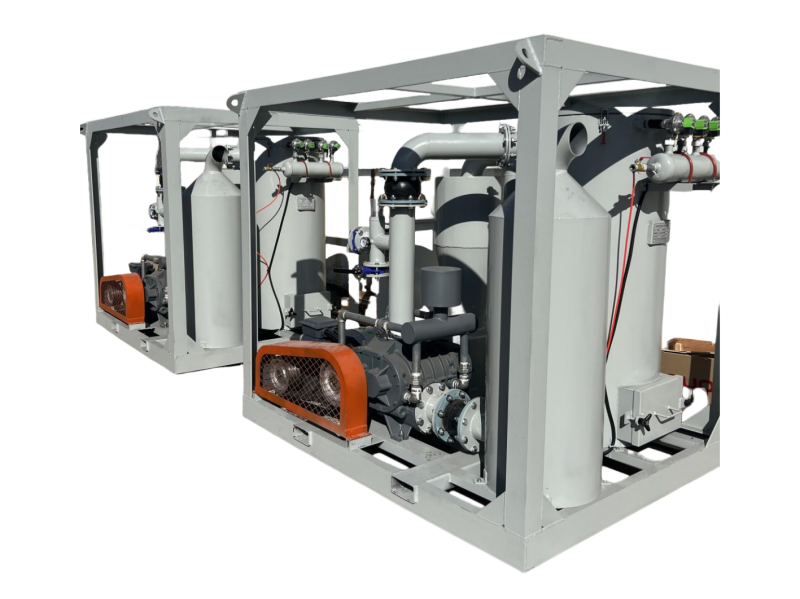

In the realm of industrial surface treatment, abrasive blasting is a cornerstone process for cleaning, finishing, and strengthening materials. However, the widespread use of abrasives—ranging from steel shot to glass beads—presents significant environmental and economic challenges. Industrial abrasive recovery and recycling machines have emerged as transformative solutions, addressing the dual goals of waste reduction and resource efficiency. These systems are designed to reclaim, clean, and reuse spent abrasives, minimizing landfill waste, lowering operational costs, and aligning with global sustainability mandates. This comprehensive guide explores the technology, applications, benefits, and future trends of abrasive recovery and recycling machines, highlighting their role in driving circular economy practices across industries.

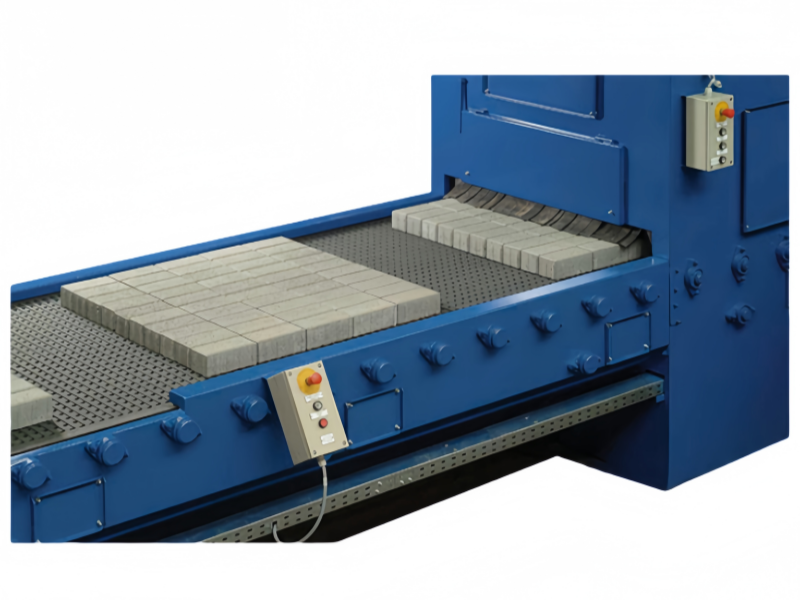

In the ever evolving world of construction, architecture, and decorative arts, stone has remained a timeless and versatile material. From the majestic facades of ancient cathedrals to the sleek countertops of modern kitchens, stone's beauty and durability have made it a preferred choice. However, to unlock its full potential and achieve the desired aesthetic and functional properties, proper surface treatment is crucial. Enter the stone shot blasting machine, a remarkable piece of equipment that has revolutionized the way stones are processed. This comprehensive introduction will delve into the various aspects of stone shot blasting machines, including their working principles, components, applications, benefits, challenges, and future trends.

In the world of architecture, design, and craftsmanship, natural stones like marble, granite, limestone, and sandstone have long been revered for their beauty, durability, and timeless appeal. From ancient monuments to modern luxury interiors, these materials serve as canvases for both functional and artistic expression. However, achieving the desired aesthetic—whether a rugged texture for exterior cladding or a refined finish for flooring—requires advanced surface treatment. Enter the marble and stone shot blasting machine—a specialized tool that combines mechanical precision with creative versatility to transform raw stone into works of art. This comprehensive guide explores the mechanics, applications, benefits, and innovations of stone shot blasting machines, showcasing their role in enhancing the beauty and functionality of natural stone.

In the architectural and design world, stone has long been revered for its beauty, durability, and timeless appeal. From ancient monuments to modern skyscrapers, natural and engineered stones are used in applications ranging from flooring and cladding to sculptures and countertops. However, achieving the desired aesthetic and functional properties often requires advanced surface treatment, and shot blasting has emerged as a versatile solution. Stone shot blasting machines are specialized systems designed to refine, texture, and clean stone surfaces, unlocking new possibilities in design while enhancing practical performance. This comprehensive guide explores the principles, applications, technical considerations, and innovative solutions in stone shot blasting, highlighting how these machines transform raw stone into artistry and functionality.

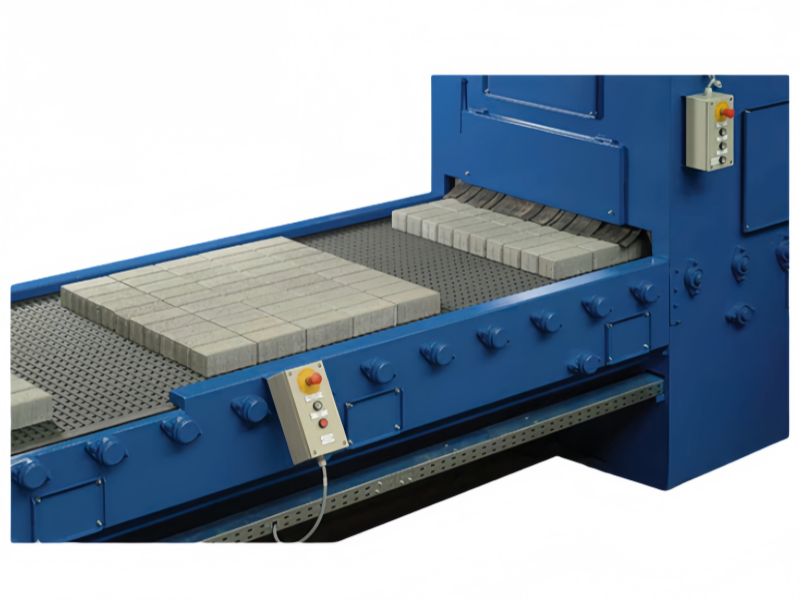

Stone shot blasting machines are specialized pieces of equipment designed to modify and enhance the surface of various types of stones. These machines have become increasingly important in the stone processing industry, offering a range of benefits from aesthetic improvements to functional enhancements. The basic principle behind a stone shot blasting machine is the use of high velocity abrasive media, such as steel shots, grits, or other suitable materials, to impact the surface of the stone. This impact action removes contaminants, alters the surface texture, and can even change the color appearance of the stone to a certain extent.

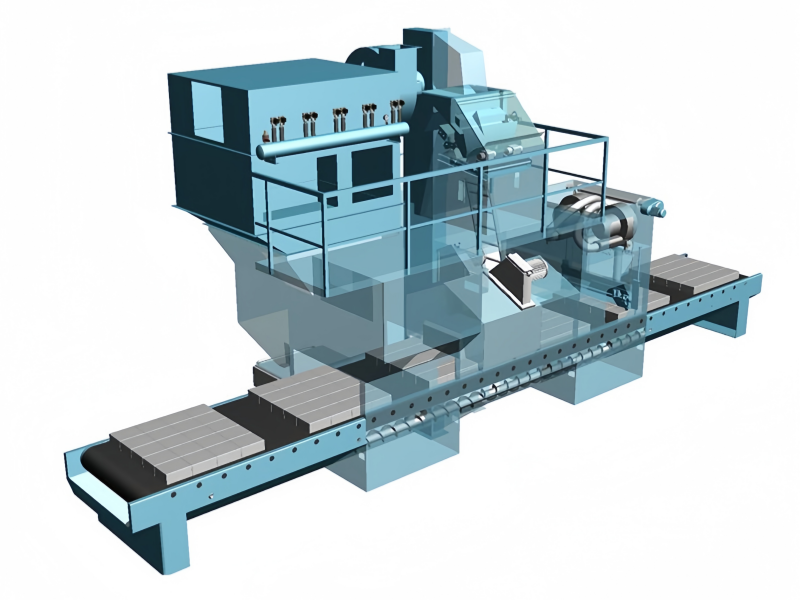

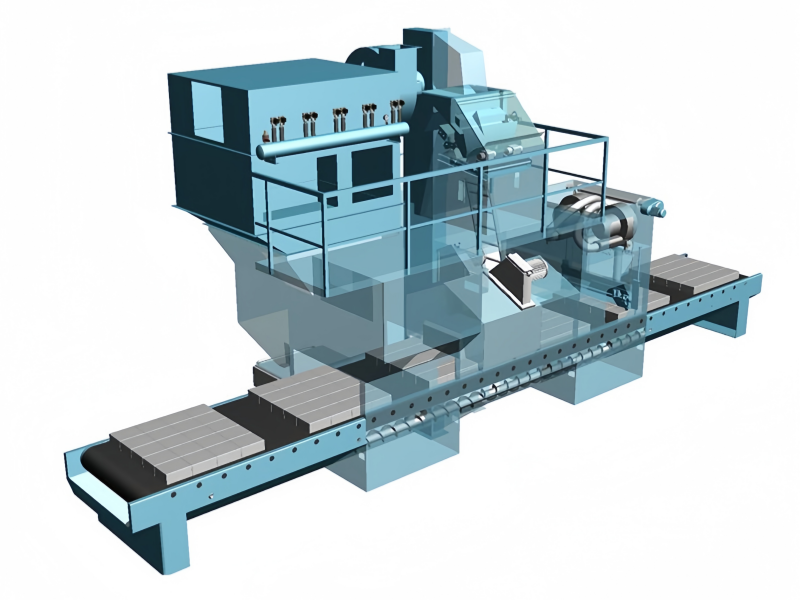

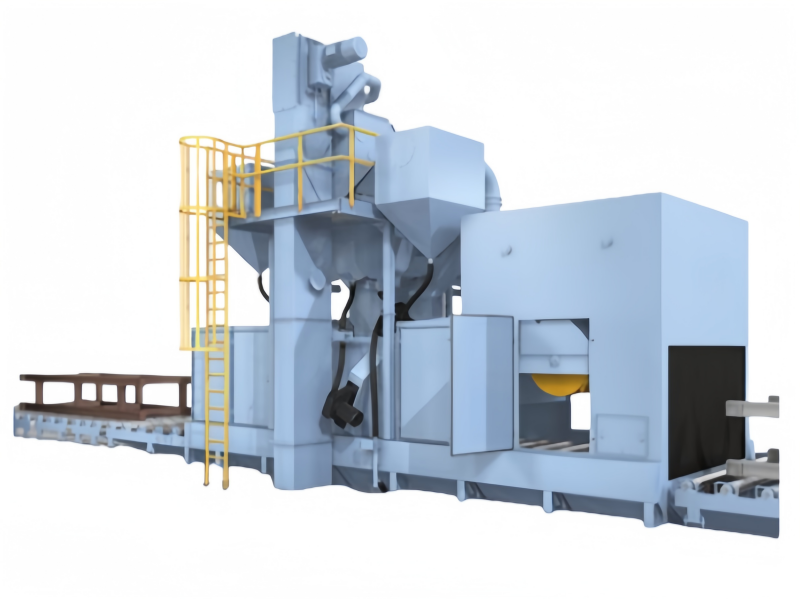

In the realm of industrial steel processing, few components are as critical as H beams—also known as I beams or universal beams. These robust structural elements, characterized by their horizontal flanges and vertical web (resembling the letter "H"), form the backbone of skyscrapers, bridges, offshore platforms, and industrial facilities worldwide. However, raw H beams straight from the mill often carry mill scale, rust, welding slag, or contaminants that compromise their performance and longevity. Enter the H beam shot blasting machine—a specialized industrial tool designed to transform these raw components into precision-engineered structures through advanced surface treatment. This comprehensive guide explores the mechanics, applications, benefits, and innovations of H beam shot blasting machines, highlighting their pivotal role in modern construction and manufacturing.

In the global landscape of steel fabrication and construction, H beams serve as the backbone of modern infrastructure, supporting skyscrapers, bridges, and industrial facilities. Ensuring their durability and structural integrity requires rigorous surface treatment, and China has emerged as a leading innovator in this field with its advanced H beam shot blasting machines. These specialized systems are designed to tackle the unique challenges of cleaning and preparing H-shaped steel profiles, combining robust engineering with cutting-edge technology to meet international standards. This comprehensive article explores the design, functionality, applications, and competitive advantages of Chinese H beam shot blasting machines, highlighting their role in driving efficiency and quality in global construction and manufacturing sectors.

In the realm of structural steel fabrication, the H beam—with its distinctive “H” cross-section—serves as a cornerstone for buildings, bridges, and industrial infrastructure. Renowned for its high strength-to-weight ratio, the H beam’s performance hinges on meticulous surface preparation to ensure durability, corrosion resistance, and seamless integration with other components. At the heart of this preparation lies the H beam shot blasting machine, a specialized system designed to clean, descale, and enhance the surface of H beams through high-velocity abrasive blasting. This comprehensive guide explores the intricacies of the H beam shot blasting process, including its technical mechanisms, industrial applications, technological advancements, and operational best practices.