Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Our company is well received by customers with perfect solutions, good product quality, performance, and after-sales

Sandblasting is a versatile and effective technique used in various industries and DIY projects. It involves propelling abrasive materials, such as sand, at high speeds onto a surface to clean, etch, or prepare it for further treatment. When it comes to sandblasting equipment, Screwfix offers a range of options to suit different needs and budgets. In this article, we will explore the world of sand blasting machines available at Screwfix, including their types, features, applications, and how to choose the right one for your specific requirements. We will also discuss safety considerations, maintenance tips, and troubleshooting common issues.

In today’s dynamic industrial landscape, businesses across sectors—from construction and manufacturing to marine and automotive—frequently require surface preparation solutions that are both cost-effective and adaptable. Sand blasting machine hireoffers a versatile, low-commitment alternative to purchasing equipment, allowing companies to access high-quality blasting technology without the upfront investment. This comprehensive guide explores the benefits, applications, considerations, and best practices of hiring sand blasting machines, highlighting how this service can optimize project outcomes while minimizing financial and operational risks.

Sand blasting, also known as abrasive blasting, is a versatile and essential technique used across industries to clean, shape, and prepare surfaces for painting, coating, welding, or other finishing processes. At the heart of this process lies the sand blasting machine—a powerful tool that propels abrasive materials (such as sand, garnet, steel shot, or glass beads) at high speeds to remove rust, paint, contaminants, or old coatings from various surfaces. For businesses and individuals seeking cost effective, flexible, and efficient surface preparation solutions, sand blasting machine rental offers a practical alternative to purchasing expensive equipment outright. This comprehensive guide explores the benefits, types, applications, and considerations of renting sand blasting machines, helping users make informed decisions for their projects.

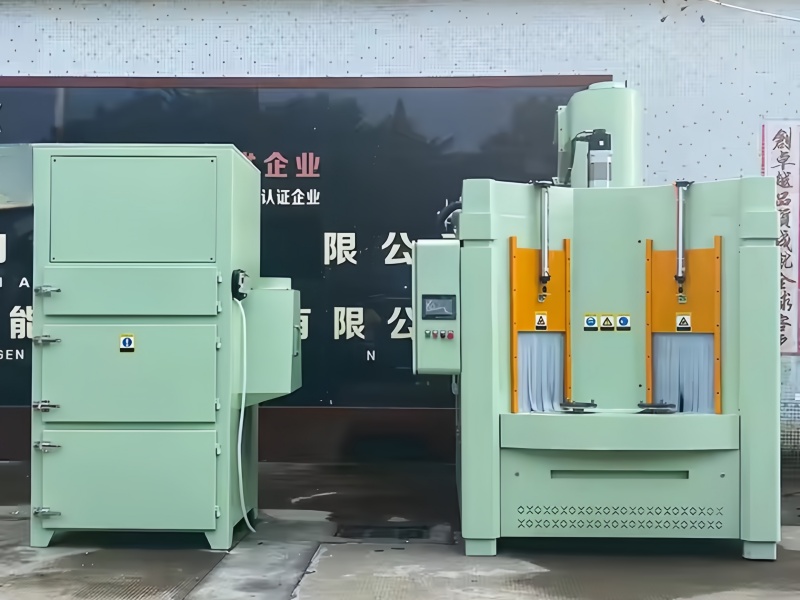

Sand blasting, a cornerstone of industrial surface treatment, has long been valued for its ability to clean, etch, and prepare surfaces with precision. As demand grows across sectors—from automotive and construction to art restoration and manufacturing—sand blasting machines have evolved to offer enhanced efficiency, safety, and environmental compliance. This comprehensive guide explores the world of sand blasting machines for sale, covering their types, applications, key features, purchasing considerations, and the latest market trends. Whether you’re a business owner, contractor, or DIY enthusiast, this overview will help you navigate the options and make an informed decision.

In the realm of industrial surface treatment, few technologies match the versatility and effectiveness of sand blasting—also known as abrasive blasting. At the core of this process lies the sand blasting machine with compressor, a dynamic duo that combines High Pressure air propulsion with abrasive media to clean, etch, or texture surfaces. From removing rust and paint to preparing metals for coating, this system is indispensable across industries, including manufacturing, construction, automotive, and marine. This detailed guide explores the mechanics, components, applications, and advancements of sand blasting machines paired with compressors, highlighting their role in modern industrial workflows.

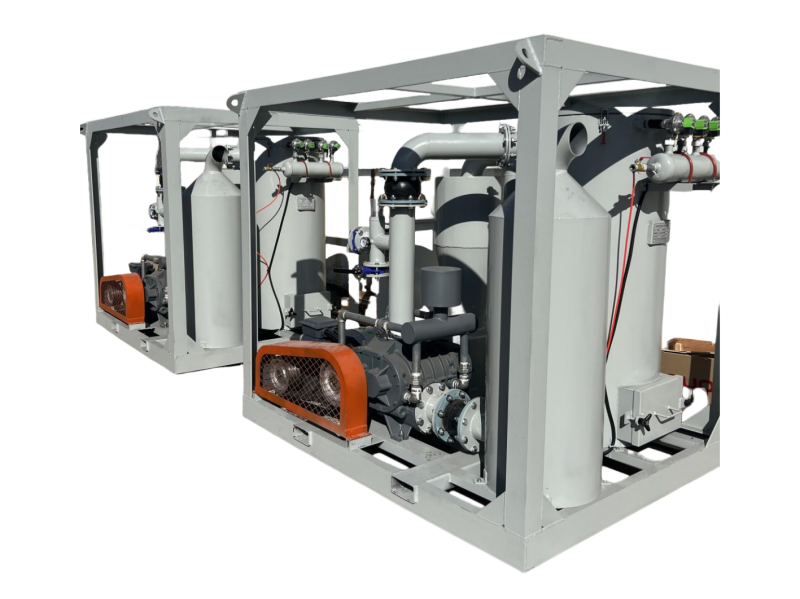

In various industrial applications such as abrasive blasting, water jet cutting, and surface finishing, garnet abrasives have gained significant popularity due to their hardness, sharp edges, and relatively low cost. However, the continuous use of fresh garnet abrasives can be costly and environmentally unfriendly. This has led to the development and increasing importance of garnet abrasive recycling systems. These systems aim to reclaim and reuse garnet abrasives, reducing both the financial and environmental burdens associated with abrasive consumption.

In the dynamic landscape of industrial blasting, where abrasive media are essential for cleaning, peening, and surface preparation, the challenge of waste management and resource sustainability has never been more critical. Abrasive recycling machines for blast operations have emerged as game-changing solutions, addressing the environmental and economic burdens of traditional blasting practices. These advanced systems are designed to reclaim, process, and reuse spent abrasives, transforming them into valuable resources while minimizing landfill waste and operational costs. This comprehensive exploration delves into the technology, applications, benefits, and future trends of abrasive recycling machines, highlighting their role in driving circular economy principles across manufacturing, construction, and beyond.

In the dynamic landscape of modern manufacturing, waterjet cutting has emerged as a versatile and precision-driven technology, capable of slicing through materials as diverse as steel, glass, and stone with unmatched accuracy. At the heart of this process lies the waterjet abrasive recycling system, a critical component that not only enhances operational efficiency but also addresses environmental and economic challenges by reclaiming and reusing abrasive media. This comprehensive guide explores the mechanics, benefits, technological advancements, and industrial applications of waterjet abrasive recycling systems, highlighting their role in driving sustainable manufacturing practices.