Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Our company is well received by customers with perfect solutions, good product quality, performance, and after-sales

Tumble belt shot blasting machines have long been vital for high-volume surface treatment of small castings, but the accumulation of abrasive media, metal debris, and dust within their components has posed significant challenges for maintenance and hygiene. Traditional designs often require hours of manual cleaning, leading to prolonged downtime, increased labor costs, and potential contamination risks. The development of easy clean designs has revolutionized these systems, prioritizing accessibility, self-cleaning features, and anti-contamination materials to minimize maintenance burdens and enhance operational efficiency.

Easy clean designs focus on:

Minimizing Trapping Points: Eliminating crevices, recesses, and horizontal surfaces where media or dust can accumulate.

Enhancing Accessibility: Designing components for quick disassembly and rapid cleaning.

Self-Cleaning Mechanisms: Integrating features that automatically remove debris during operation.

Hygienic Material Selection: Using non-porous, corrosion-resistant materials that resist fouling and are easy to sanitize.

This technological advancement is particularly critical for industries requiring high cleanliness standards, such as medical device manufacturing, food processing, and aerospace, where even minor contamination can lead to product failures or regulatory non-compliance.

Tumble belt shot blasting machines have long been essential for high-volume surface treatment of small castings, but the inherent abrasion from continuous exposure to steel grit, cast iron parts, and high-velocity abrasive streams poses significant challenges to belt durability. Traditional steel or rubber belts often require frequent replacement, leading to unplanned downtime, increased maintenance costs, and production inefficiencies. The development of anti-wear belt technologies has revolutionized these systems, extending belt service life, reducing operational costs, and enhancing overall machine reliability.

Anti-wear belts are engineered to:

Withstand millions of cycles of abrasive impact without degradation

Maintain dimensional stability under high-temperature and corrosive environments

Minimize particle trapping and media contamination

Enable faster cleaning and reduced maintenance interventions

This technological advancement is particularly critical for industries processing abrasive materials like cast iron, stainless steel, and high-chrome alloys, where belt wear was once a limiting factor in system productivity.

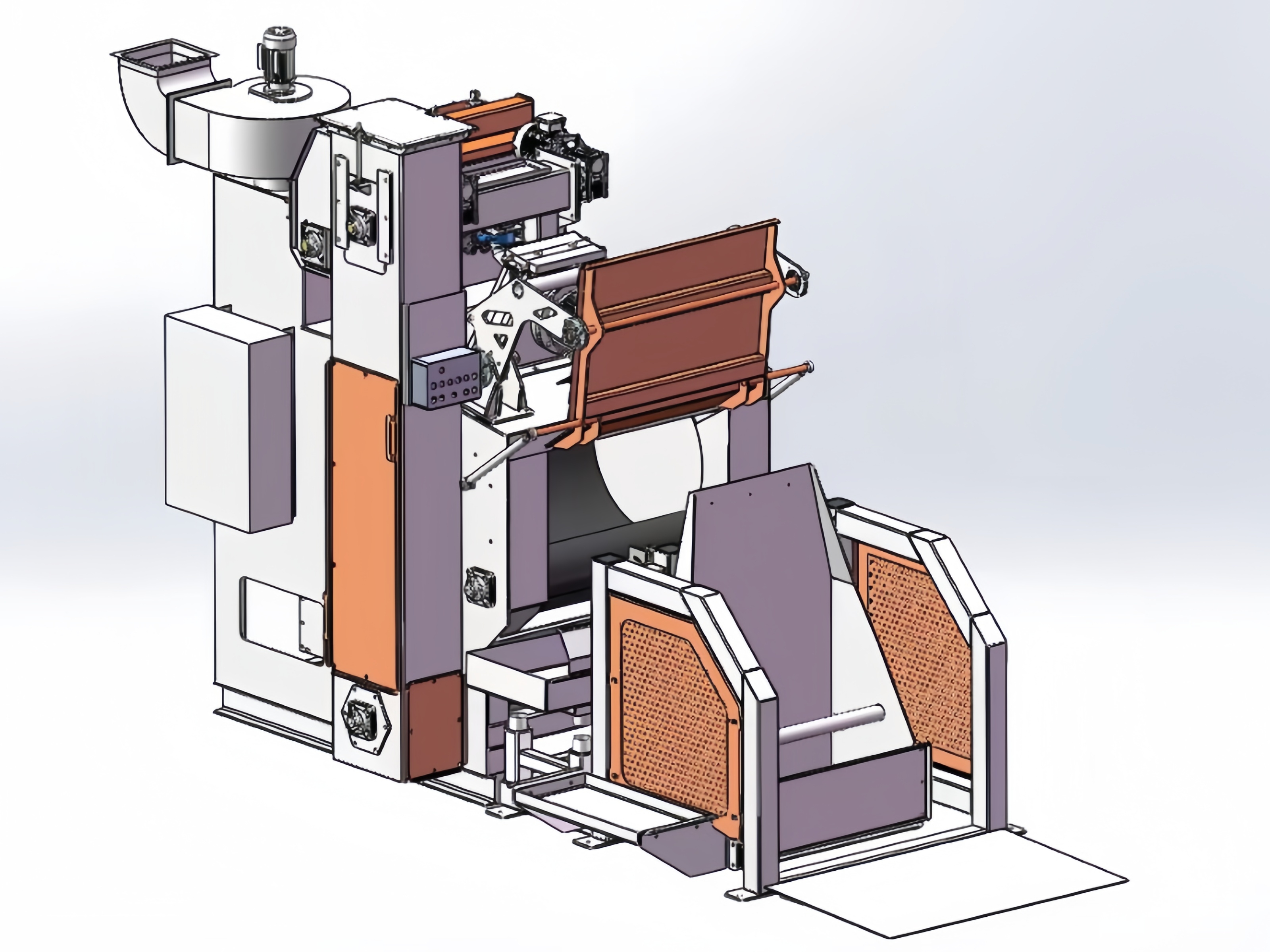

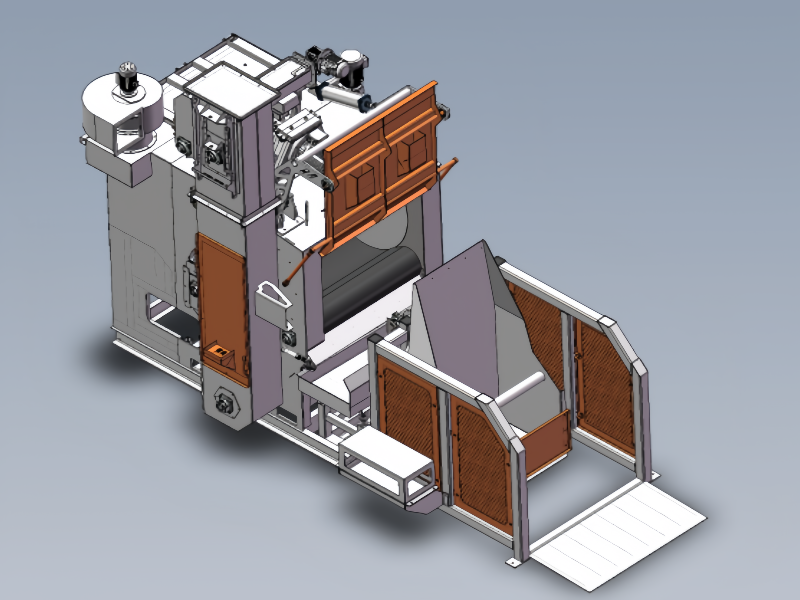

In the realm of industrial surface treatment, heavy duty tumble belt shot blasting machines stand as robust and reliable workhorses, specifically engineered to handle the most demanding and arduous tasks. These machines are designed to cater to industries that deal with large scale production of heavy and bulky workpieces, where traditional shot blasting methods may fall short.

The heavy duty tumble belt shot blasting machine represents a significant advancement in shot blasting technology, combining the power of high velocity abrasive media projection with a unique tumble belt mechanism. This combination allows for thorough and efficient surface cleaning, descaling, and preparation of a wide range of components. As industries strive for increased productivity, improved product quality, and cost effective manufacturing processes, the role of heavy duty tumble belt shot blasting machines has become increasingly crucial. This article will provide an in depth exploration of these machines, covering their design, functionality, applications, advantages, and future prospects.

Tumble belt shot blasting machines represent a specialized category of surface treatment equipment designed to process small castings, forgings, and machined parts in high-volume production environments. Unlike batch-type tumble machines or conveyor-based systems, these machines utilize a continuous belt mechanism to transport components through a blasting chamber, combining the advantages of thorough tumbling action with efficient throughput. This makes them ideal for parts ranging from 5 mm to 150 mm in size, such as automotive engine components, hardware fasteners, and agricultural machinery parts, which require consistent cleaning, deburring, or surface finishing.

In the ever evolving landscape of industrial manufacturing, the pursuit of higher efficiency, enhanced productivity, and improved quality control has led to the development of advanced machinery and technologies. Among these, shot blasting machines with automated loading systems have emerged as a game changer in surface treatment processes. These innovative machines combine the powerful capabilities of traditional shot blasting with the convenience and precision of automated material handling, offering significant advantages over manual loading counterparts.

Shot blasting is a well established technique used to clean, descale, and prepare surfaces by propelling abrasive media at high speeds onto workpieces. By integrating an automated loading system, manufacturers can streamline the entire shot blasting operation, reducing human error, minimizing downtime, and increasing throughput. This article will explore the various aspects of shot blasting machines with automated loading systems, including their design, functionality, benefits, applications, and future prospects.

Precision shot blasting machines represent a specialized class of surface treatment equipment designed to handle fragile, high-value components without compromising their structural integrity or functional performance. Unlike conventional blasting systems, these machines integrate advanced control technologies, specialized abrasive media, and ergonomic chamber designs to achieve micron-level precision in surface finishing, deburring, and cleaning. Delicate components—ranging from aerospace turbine blades to medical implants—often require surface treatments that remove minimal material while adhering to strict roughness tolerances (e.g., ±0.1 μm) and defect-free standards.

The key challenges in precision blasting for delicate parts include:

Preventing micro-damage (e.g., surface cracking, material thinning)

Achieving uniform treatment across complex geometries

Controlling abrasive impact energy to nanojoule-level precision

Minimizing particulate contamination in critical applications

Modern precision systems address these through a combination of variable speed control, intelligent process monitoring, and specialized abrasive delivery mechanisms, setting new standards for surface treatment in industries where margin for error is negligible.

In the vast landscape of industrial manufacturing, industrial grade shot blasting machines stand as formidable workhorses, playing a pivotal role in surface treatment processes. These robust machines are engineered to handle the most demanding tasks, making them indispensable in a multitude of industries. From the automotive sector to heavy construction, and from metal fabrication to aerospace, industrial grade shot blasting machines are utilized to clean, descale, deburr, and prepare surfaces for further processing.

As industries strive for higher productivity, superior product quality, and cost effective operations, the significance of industrial grade shot blasting machines continues to grow. This article will comprehensively explore the various aspects of these machines, including their design, functionality, applications, benefits, and the future trends that will shape their evolution.

Shot blasting machines are industrial tools designed to clean, strengthen, or finish metal surfaces by propelling abrasive media at high speeds. The integration of variable speed control technology has revolutionized their functionality, enabling precise adjustments to operational parameters for optimized performance across diverse applications. This technology addresses the limitations of traditional fixed-speed systems, where one-size-fits-all settings often led to inefficiencies, surface damage, or inconsistent results.

Variable speed control in shot blasting machines primarily refers to the ability to adjust:

The rotational speed of the impeller wheels that propel abrasive media

The conveyor belt speed for workpiece transportation

The flow rate of abrasive material delivery

By fine-tuning these variables, operators can tailor the blasting process to specific material types, surface requirements, and production scales. For instance, delicate components like aerospace alloys may require lower impeller speeds to avoid micro-damage, while rugged automotive parts might need higher speeds for aggressive de-rusting.