Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

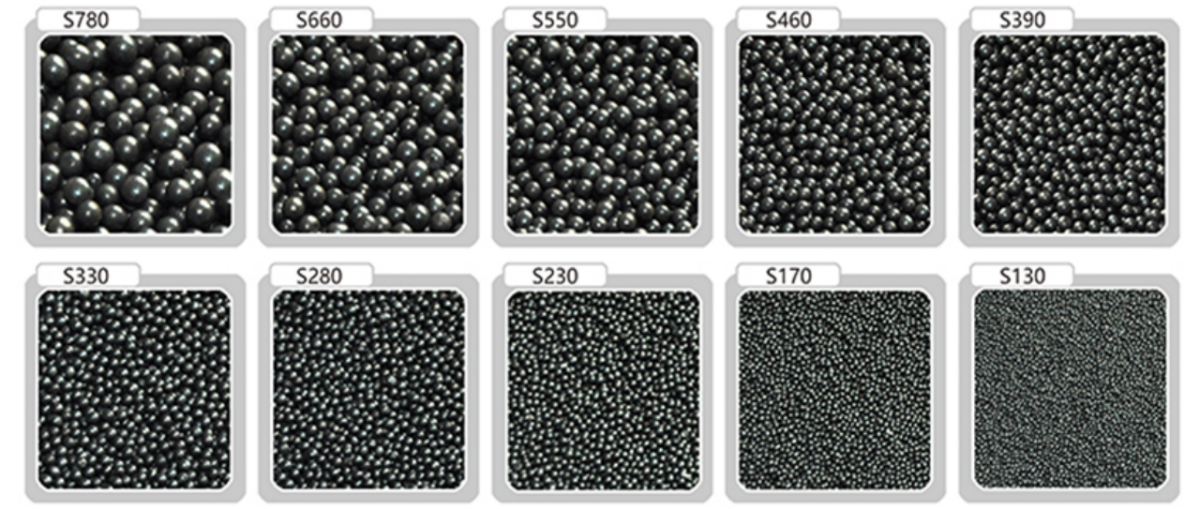

1.Name:Cast Steel Shot

2.Model: S50-S930

3.Hardness:HRC40-50

Definition

Low-Carbon Steel Shot is a type of steel shot with a carbon content typically ranging from 0.05% to 0.3%. It is designed for applications that require a softer, more ductile material to minimize surface damage and reduce the risk of breakage。

Characteristics

1.Lower Hardness: With a hardness range of approximately 40-50 HRC, low-carbon steel shot is softer than high-carbon steel shot。

2.Ductility and Impact Resistance: It has a bainite microstructure, which provides good impact resistance and reduces the risk of sudden breakage。

3.Reduced Machine Wear: Due to its lower hardness, it causes less wear on blasting equipment compared to high-carbon steel shot。

4.Recyclability: Low-carbon steel shot is fully recyclable, making it an environmentally friendly option。

Applications

Low-carbon steel shot is widely used in various industrial processes, including:

1.Surface Cleaning: Removing rust, scale, and old paint from metal surfaces。

2.Descaling and Deburring: Cleaning and smoothing surfaces, especially on softer materials。

3.Shot Peening: Used for surface treatment on softer materials to improve fatigue resistance without causing excessive surface damage。

4.Foundry Cleaning: Removing sand and scale from castings。

5.Pre-Treatment Before Painting: Preparing metal surfaces for coating by providing a clean and uniform base。

Advantages

1.Minimized Surface Damage: The softer nature of low-carbon steel shot reduces the risk of damaging delicate or thin-walled parts。

2.Longer Equipment Lifespan: Lower hardness means less wear on blasting machinery。

3.Cost-Effective: While it may not be as durable as high-carbon steel shot, its flexibility and reduced machine wear can lead to long-term cost savings。

4.Sustainability: Fully recyclable, supporting eco-friendly industrial practices。

Selection Considerations

When choosing between low-carbon and high-carbon steel shot, consider the specific requirements of your application.

Low-carbon steel shot is ideal for:

1.Applications requiring a gentler, more controlled impact.

2.Processes where surface damage needs to be minimized.

3.Situations where equipment wear is a concern。

In contrast, high-carbon steel shot is better suited for heavy-duty applications that demand higher hardness and wear resistance。

In summary, low-carbon steel shot offers a versatile and durable solution for industrial surface treatment processes, particularly where a softer, more ductile material is required. Its reduced impact on machinery and surfaces, combined with its recyclability, makes it a valuable choice for many applications。

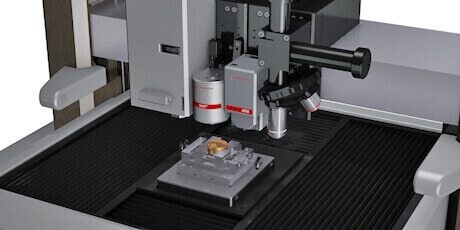

Hardness Tester

1. No friction spindle,High testing accuracy.

2. Stable construction,High testing efficiency.

3. High precision micrometer readings metering system.

4. Testing process automation,no human operator error.

5. Accuracy class:GB/T4340.2/ISO6507-2 and American ASTME92.

Microscope

1. To identificate and analyze the organizational structure of various metals and alloys.

2. The instrument is widely used in factories or laboratories to identify the quality of castings,inspect raw materials,or Microstructure analysis after-treatment.

Three Element Analyzer

1. A newer multi-element analyzer.

2. It is used in detection of variety of elements such as :Si/Mn/P/Cr/Ni/Mo/Cu/Ti of all kinds of material such as:ball mill cast iron,cast iron,ductile iron,alloy cast iron and stainless steel ,carbon steel,low alloy steel,high alloy steel etc. The analysis result is fast and accurate.

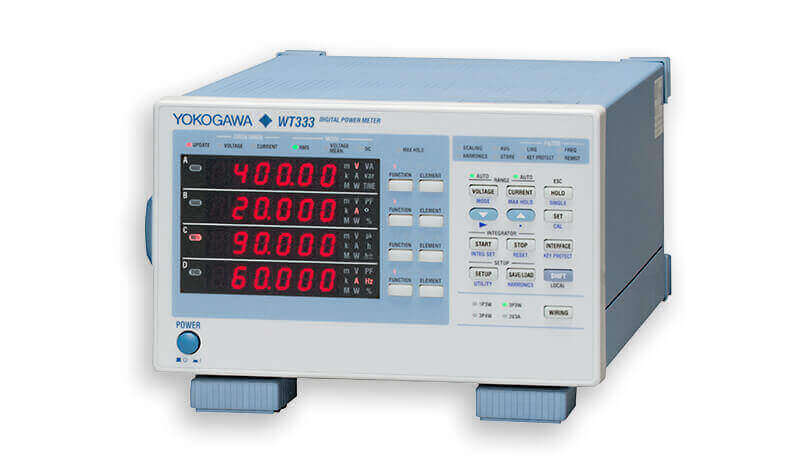

Carbon & Sulfur Analyzer

1. The equipment is one of the high-tech products and a collection of optical ,mechanical and electrical ,computer,analysis technology.

2. It has the advantage of wide measuring range,strong anti-jamming capability,complete functions,simple operation,analysis results accurate and reliable,ti is the ideal analysis equipment of the 2 element of carbon and sulfur in industries determination.