Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Wet Sand Blasting Machine

2.Model:1610W-GL

3.Operation Way: Manual

Introduction

A wet sand blasting machine, also known as a vapor blaster or water blaster, is a versatile tool used for surface cleaning, degreasing, deburring, descaling, and removing paint, chemicals, and oxidation. It works by combining water and abrasive media to create a slurry that is blasted onto the surface, providing a controlled and precise cleaning or finishing process.

How Wet Sand Blasting Machines Work?

Wet sand blasting machines use a mixture of water and abrasive particles to create a slurry. This slurry is then propelled at high pressure onto the surface to be cleaned or treated. The water in the slurry helps to reduce dust levels significantly compared to dry blasting, making the process cleaner and safer. It also prevents the abrasive particles from embedding into the workpiece surface, resulting in a smoother finish.

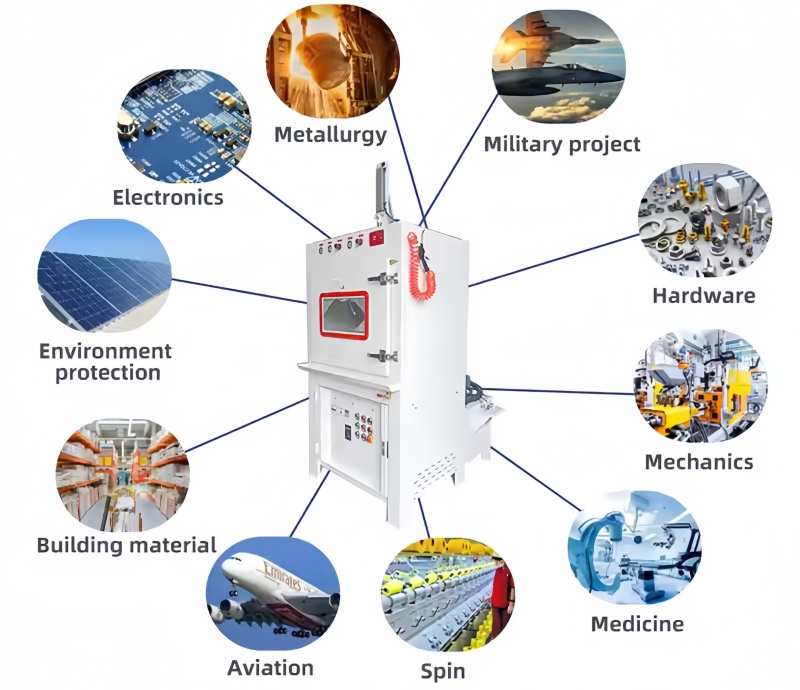

Applications of Wet Sand Blasting Machines

1.Surface Cleaning and Preparation: Wet sand blasting is highly effective for cleaning and preparing surfaces for painting, bonding, or other treatments. It can remove rust, scale, and old paint from metal surfaces without causing damage.

2.Degreasing and Deburring: The process is also used for degreasing and deburring metal parts, ensuring a clean surface for further processing.

3.Descaling: Wet sand blasting can remove scale from industrial equipment, extending its lifespan and improving efficiency.

4.Art and Design: Artists and designers use wet sand blasting to create intricate designs on materials like glass, metal, and stone. The precision and control offered by wet sand blasting make it ideal for delicate work.

Benefits of Wet Sand Blasting

1.Reduced Dust Levels: The water in the slurry suppresses dust, making the process much cleaner and safer for operators and the environment.

2.Less Surface Damage: Wet sand blasting reduces the risk of surface damage and contamination, resulting in a cleaner and more consistent finish.

3.Energy Efficiency: Wet sand blasting machines are generally more energy-efficient than their dry counterparts.

4.Environmental Friendliness: The process generates less waste and requires less water than traditional dry blasting methods.

5.Enhanced Visibility: The reduced dust levels improve visibility during the blasting process, enhancing safety.

Safety Measures for Wet Sand Blasting

1.Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including respirators, safety goggles, protective suits, and gloves.

2.Ventilation: Ensure the blasting area is well-ventilated to minimize dust and chemical exposure.

3.Regular Breaks: Take regular breaks to reduce fatigue and heat stress.

4.Equipment Maintenance: Regularly inspect and maintain the blasting equipment to prevent malfunctions.

5.Training: Ensure all operators are properly trained in equipment use and safety procedures.

Choosing the Right Wet Sand Blasting Machine

When selecting a wet sand blasting machine, consider the following factors:

1.Capacity: Choose a machine with the appropriate capacity for your needs.

2.Versatility: Look for machines that offer multiple functions, such as wet blasting, dry blasting, and blow-off capabilities.

3.Portability: Consider the portability of the machine, especially if you need to move it around different job sites.

4.Ease of Use: Select a machine with user-friendly controls and easy setup.

Wet sand blasting machines offer a range of benefits over traditional dry blasting methods, making them a preferred choice for many industries where precision, cleanliness, and environmental sustainability are crucial.