Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

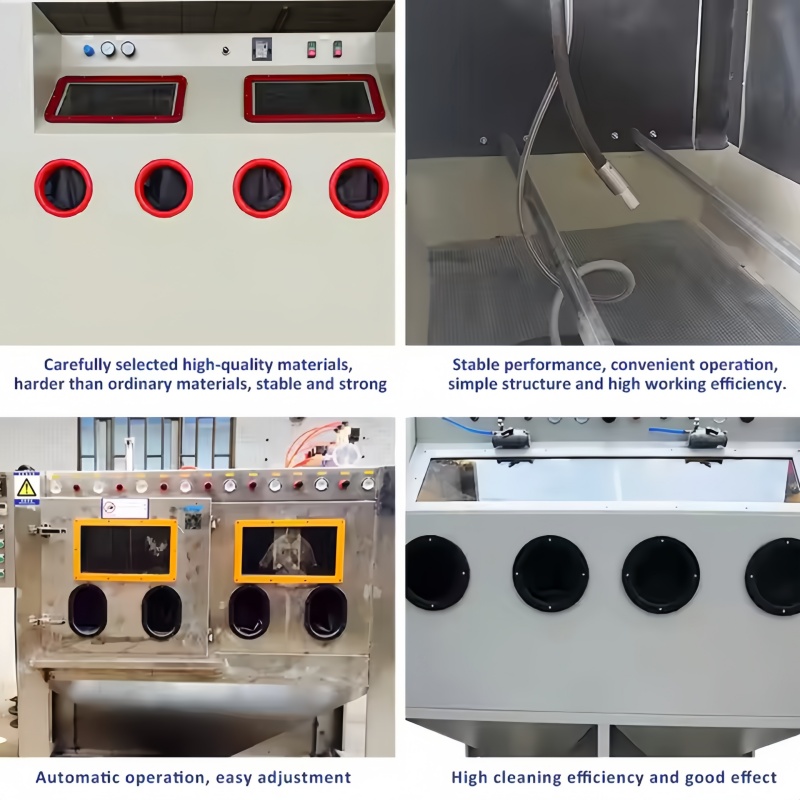

1.Name:Wet Sand Blasting Machine

2.Model:2012W-SQ

3.Operation Way: Manual

Wet Sand Blasting Machine: An In-Depth Overview

Definition

A Wet Sand Blasting Machine, also known as a wet abrasive blasting machine, vapor blasting machine, or slurry blasting machine, is an industrial device that uses a pressurized mixture of water and abrasive media to clean or finish surfaces. This process is an alternative to traditional dry sandblasting and offers several environmental and operational advantages.

Components

1.High-Volume Pump: This specialized pump mixes the abrasive media with water to create a slurry.

2.Nozzle: The slurry is sent to a nozzle where regulated compressed air is used to adjust the pressure of the slurry as it is blasted onto the surface.

3.Blast Tank: The slurry is circulated from the blast tank to the blast gun by a blast pump.

4.Compressed Air System: Compressed air is used to accelerate the slurry mixture, applying it to the target workpiece.

Working Principle

The process begins with the high-volume pump mixing abrasive media with water to form a slurry. This slurry is then sent to the nozzle, where regulated compressed air propels it onto the surface at ultr

a-high speeds. The slurry is continuously recirculated from the blast tank to the blast gun, ensuring efficient use of materials and minimal waste.

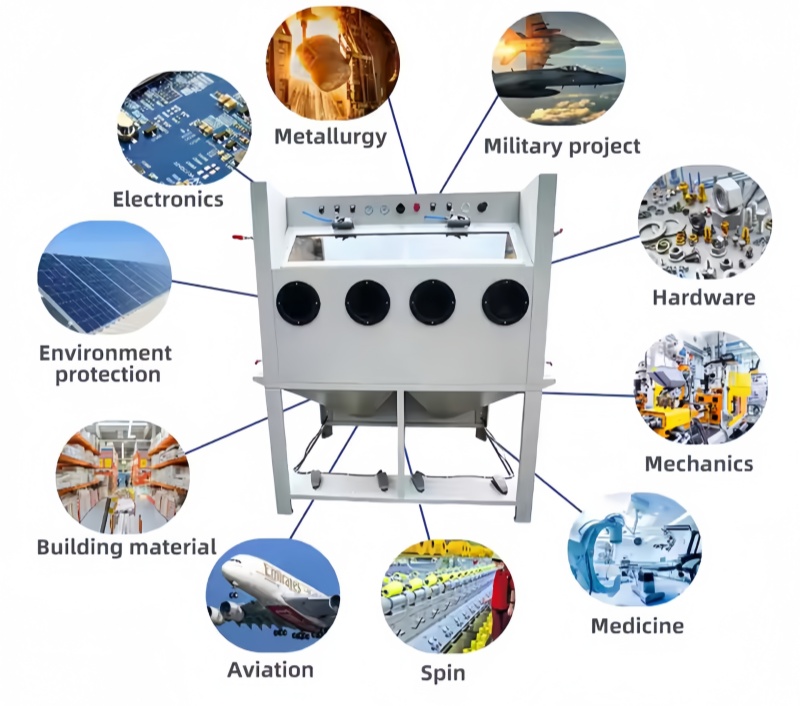

Applications

Wet sand blasting machines are used in various industries for:

1.Cleaning and Degreasing: Effective in removing dirt, grease, and contaminants from surfaces.

2.Deburring and Descaling: Removes burrs and scales from metal surfaces.

3.Paint and Chemical Removal: Capable of stripping old paint and chemical coatings.

4.Surface Profiling and Texturing: Ideal for creating specific surface profiles and textures on metals and other substrates.

5.High-Precision Composite Etching: Used for precision etching in bonding applications.

Advantages

6.Reduced Dust Levels: The water in the slurry suppresses dust, making the process much cleaner and safer for workers and the environment.

7.Less Surface Damage: The water helps to cool the workpiece, reducing the risk of heat damage and static electricity.

8.Enhanced Precision: Allows for greater control over the blasting process, resulting in more consistent and precise finishes.

9.Environmental Sustainability: Uses less water and generates less waste compared to traditional dry blasting methods.

10.Versatility: Suitable for a wide range of materials and applications, from delicate surfaces to heavy-duty industrial components.

Conclusion

The Wet Sand Blasting Machine is a versatile and environmentally friendly tool that offers significant advantages over traditional dry blasting methods. Its ability to reduce dust, minimize surface damage, and provide precise finishes makes it an ideal choice for a variety of industrial applications. As technology continues to advance, wet sand blasting is likely to become even more integral to advanced manufacturing and surface treatment processes.