Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

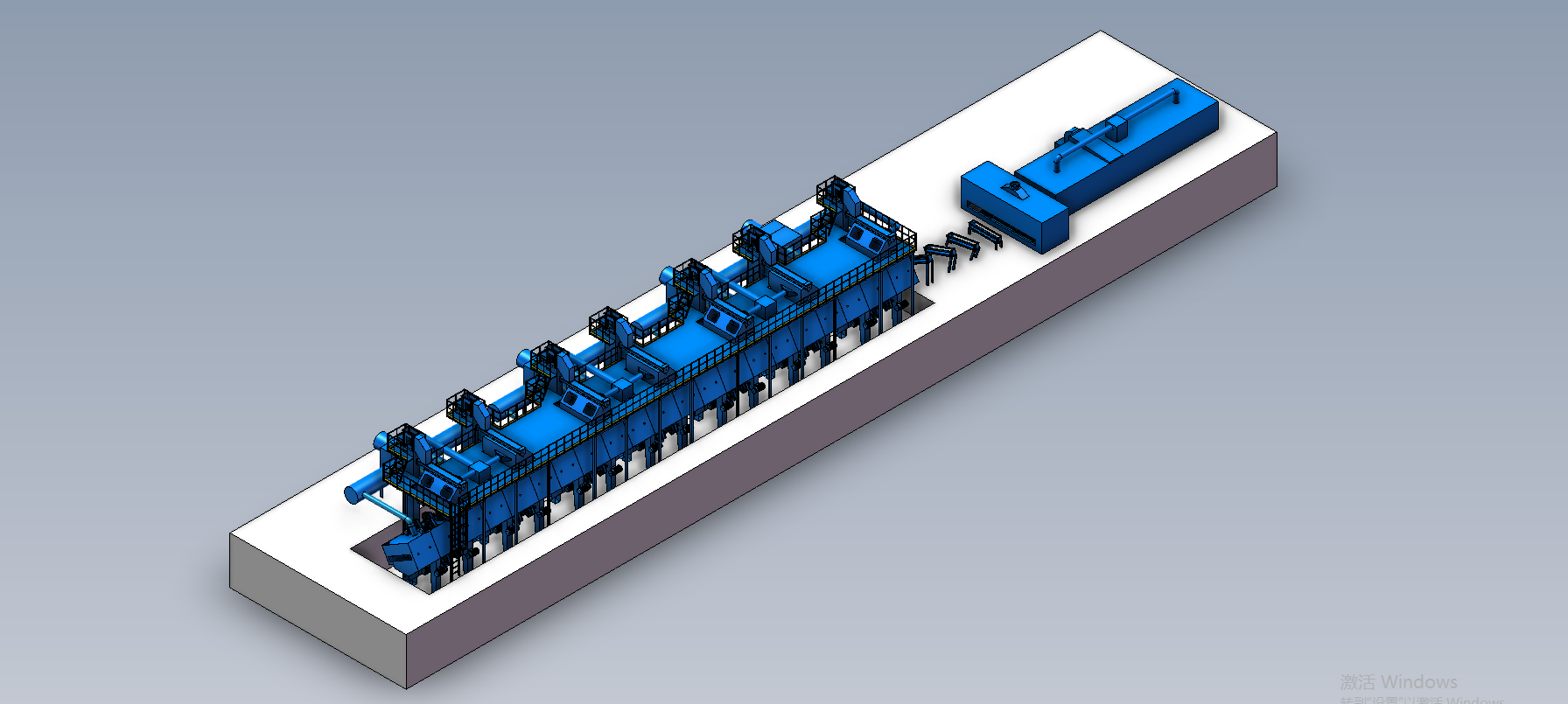

1.Name:Steel Coil Shot Blasting Machine

2.Model:MTR

3.It Is Used For Steel Coil Shot Blasting

Working Principle

A steel coil shot blasting machine operates by mechanically propelling abrasive media, such as steel shots or grits, at high velocity towards the surface of steel coils. The impact of the abrasive material removes contaminants, rust, or old coatings, leaving the surface clean and prepared for subsequent processing。

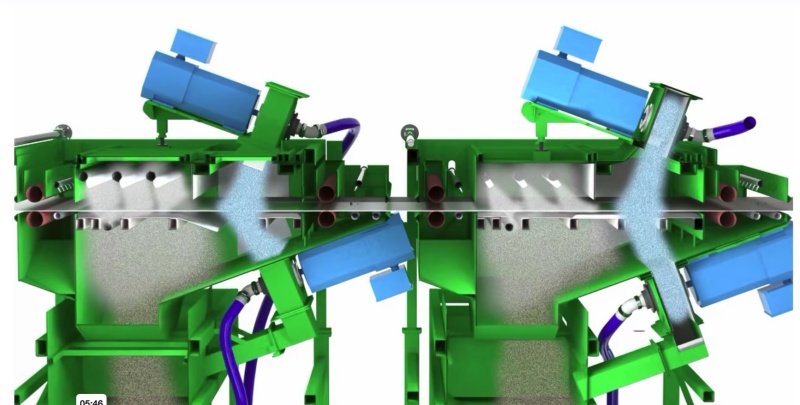

The key component of this machine is the blast wheel, which converts electrical energy into kinetic energy to propel the abrasive media. The blast wheel consists of blades, an impeller, and a control cage. The control cage regulates the flow and direction of the abrasive media, ensuring it hits the steel coils at the correct angle and speed。

The process involves several steps:

1.Loading the Steel Coils: The steel coils are loaded into the blasting chamber, which can be done manually or via an automated system。

2.Blasting Operation: The blast wheel propels the abrasive media at high speed towards the steel coils. The impact removes rust, scale, and other contaminants。

3.Media Recovery: The used media, along with debris and contaminants, falls to the bottom of the chamber. An elevator lifts this mixture to a separator, where reusable media is separated from waste materials。

4.Dust Collection: A dust collector captures fine particles and dust, maintaining a clean environment。

5.Unloading the Steel Coils: After blasting, the clean steel coils are removed from the chamber, ready for further processing。

Applications

Steel coil shot blasting machines are widely used in various industries for the following purposes:

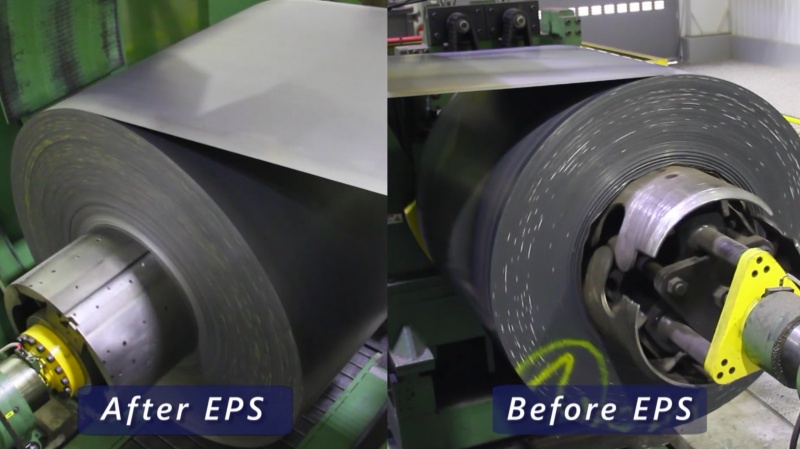

1.Preparation for Coating: The machine prepares the surface of steel coils for painting or coating by removing rust and scale, ensuring better adhesion of the coating。

2.Surface Cleaning: It effectively removes contaminants from steel coils, improving their surface quality。

3.Stress Relief and Strengthening: By creating a rough surface, the machine can change the stress state of the steel coils from tensile to compressive, thereby increasing their service life。

Advantages

1.Efficiency: The machine can handle large volumes of steel coils, making it suitable for high-throughput operations。

2.Automation: Modern steel coil shot blasting machines come with automated controls that enhance operational efficiency and reduce the need for manual intervention。

3.Environmental Friendliness: The process is environmentally friendly as it does not use harsh chemicals and the abrasive media can be recycled。

4.Surface Quality: It delivers superior surface preparation, resulting in a clean surface that enhances paint adhesion and overall durability of steel components。

In summary, the steel coil shot blasting machine is an essential tool in industries that require high-quality surface preparation of steel coils. Its efficient and environmentally friendly operation makes it a preferred choice for many manufacturing processes.