Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Sand Blasting Machine

2.Model:MS

3.Operation Way: Manual

Sandblasting machines are versatile tools used for surface cleaning, stripping, and preparation across various industries.

Here’s an overview of the different types of sandblasting machines and their applications:

Types of Sandblasting Machines

Gravity-Fed Sandblaster

1.Description: The abrasive material is loaded into a hopper at the top of the machine and pulled down by gravity when the nozzle is activated. It is simple to operate but less powerful.

2.Applications: Suitable for small-scale projects, hobbyist-level blasting, and lighter surface cleaning tasks.

Pressure Pot Sandblaster

1.Description: This machine uses a pressurized tank to force the abrasive media through a nozzle at high velocity. It provides a continuous and powerful flow of abrasives.

2.Applications: Ideal for heavy-duty applications such as removing heavy corrosion, thick coatings, or preparing large surfaces for painting.

Siphon Sandblaster

1.Description: It operates using suction to draw the abrasive media through a hose and deliver it to the nozzle. It is less expensive upfront but has higher ongoing costs.

2.Applications: Best suited for cleaning lighter surface materials where a gentle touch is needed.

Wheel Abrator

1.Description: This machine uses a rotating wheel or set of paddles to propel metallic abrasives like steel grit or steel shot onto the surface. It is highly effective for large-scale industrial applications.

2.Applications: Rust removal, die-casting cleaning, shot peening, and surface preparation in industries like shipbuilding and automotive.

Vapor Sandblaster

1.Description: This type injects a mixture of water, abrasive media, and compressed air into the blast hose. The water helps suppress dust and keeps surface temperatures lower.

2.Applications: Used for cleaning and degreasing, particularly in applications sensitive to temperature changes.

Portable Sandblaster

1.Description: These machines are versatile and can be easily moved around different job sites. They typically consist of a blasting gun connected to an air compressor.

2.Applications: Ideal for small-scale projects, automotive restoration, graffiti removal, and surface preparation tasks.

Cabinet Sandblaster

1.Description: An enclosed system with gloves and viewing windows that protect the operator from dust and debris. The abrasive material is stored in a hopper and delivered through a nozzle.

2.Applications: Used for delicate or intricate projects requiring precision, such as jewelry making, dental laboratories, and electronics manufacturing.

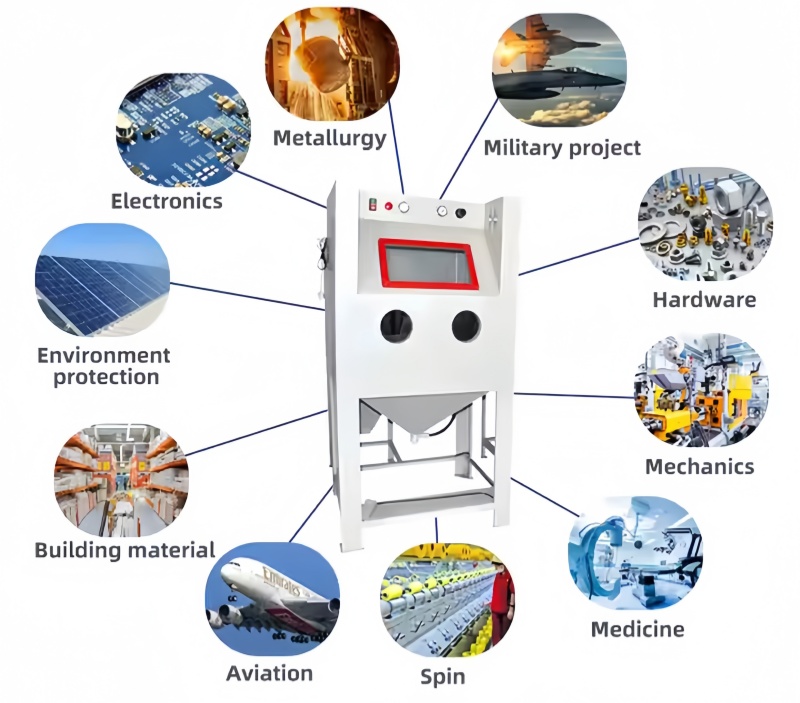

Applications of Sandblasting Machines

1.Industrial Cleaning: Removing rust, paint, and other contaminants from metal surfaces in industries like shipbuilding, automotive, and construction.

2.Surface Preparation: Preparing surfaces for painting, bonding, or other coating activities by achieving a uniform surface texture.

3.Art and Design: Creating intricate patterns and designs on materials like wood, metal, and glass.

4.Maintenance: Cleaning smaller tools and machinery to prevent wear and tear.

5.Concrete Cleaning: Cleaning streets, pavements, and other concrete surfaces.

Safety Considerations

1.Personal Protective Equipment (PPE): Respirators, blast helmets, protective gloves, and blast suits are essential to protect against airborne particles and abrasive media.

2.Ventilation: Ensure adequate ventilation in the work area to prevent the buildup of dust and debris.

3.Regular Maintenance: Regularly inspect and maintain the sandblasting machine to ensure it is in good working condition.

Sandblasting machines are available from various suppliers, including Titan, Cyclone, and Amazon, each offering a range of products to suit different needs.