Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

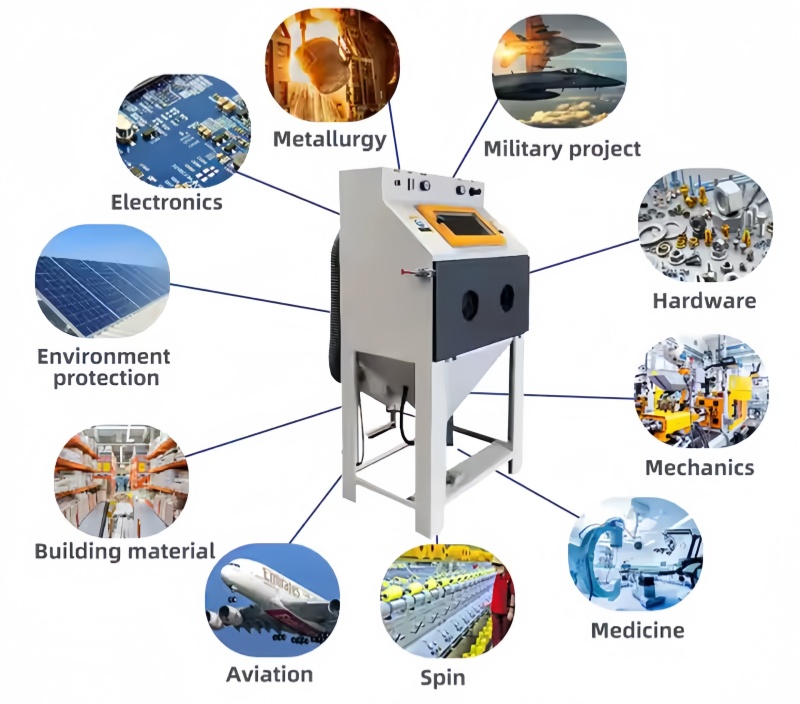

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Sand Blasting Cabinet

2.Model:MS

3.Operation Way: Manual

A sand blasting cabinet is an enclosed system designed to safely and efficiently perform sand blasting operations. It is widely used in various industries for surface cleaning, paint stripping, and preparation. Here’s a detailed overview of sand blasting cabinets, including their features, benefits, and safety considerations.

Features of Sand Blasting Cabinets

1.Enclosed Design:

Sand blasting cabinets are fully enclosed to contain dust and debris, protecting the operator and the surrounding environment.

They typically feature a viewing window and gloves for the operator to control the blasting process without direct exposure to the abrasive materials.

2.Efficient Dust Collection:

Many cabinets come with built-in dust collection systems to filter out fine particles, reducing the risk of inhalation and maintaining a cleaner work environment.

3.Versatile Abrasive Media:

Sand blasting cabinets can use a variety of abrasive media, including aluminum oxide, glass beads, steel grit, and garnet sand, depending on the specific application.

4.User-Friendly Operation:

Cabinets are designed for easy operation, with features like adjustable blast pressure, ergonomic controls, and easy media loading and disposal.

Applications of Sand Blasting Cabinets

1.Industrial Cleaning: Removing rust, paint, and other contaminants from metal surfaces.

2.Surface Preparation: Preparing surfaces for painting, bonding, or other coatings.

3.Art and Design: Creating intricate patterns and designs on materials like glass, wood, and metal.

4.Maintenance: Cleaning and restoring small tools and machinery.

Safety Considerations

1.Respiratory Protection:

Inhalation of dust and particles is a significant hazard. Operators should wear NIOSH-certified respirators to prevent exposure to harmful substances such as crystalline silica.

2.Eye and Skin Protection:

Flying particles can cause eye injuries and skin abrasions. Operators should wear safety goggles, gloves, and protective clothing.

3.Noise Hazards:

Sand blasting generates high levels of noise, which can lead to hearing loss. Ear protection, such as earplugs or noise-canceling headphones, is essential.

4.Dust Control:

Proper ventilation and dust collection systems are crucial to minimize the risk of dust explosions and inhalation of toxic particles.

5.Regular Maintenance:

Regular inspection and maintenance of the sand blasting cabinet and associated equipment are essential to ensure safe and efficient operation.

Health Risks of Sand Blasting

Sand blasting poses several health risks, particularly related to inhalation of fine particles:

1.Respiratory Issues: Inhalation of silica dust can lead to silicosis, lung cancer, and chronic obstructive pulmonary disease (COPD).

2.Skin and Eye Injuries: Direct contact with abrasive materials can cause skin abrasions and eye irritation.

3.Hearing Loss: High noise levels during sand blasting can cause permanent hearing damage.

Choosing the Right Sand Blasting Cabinet

When selecting a sand blasting cabinet, consider the following factors:

1.Size and Capacity: Choose a cabinet that fits the size of the items you need to blast.

2.Dust Collection System: Ensure the cabinet has an effective dust collection system to minimize airborne particles.

3.Media Compatibility: Select a cabinet that can handle the type of abrasive media you plan to use.

4.Safety Features: Look for cabinets with built-in safety features, such as blast-resistant windows and ergonomic controls.

By understanding the features, applications, and safety considerations of sand blasting cabinets, you can effectively utilize this powerful tool while minimizing potential health risks.