Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

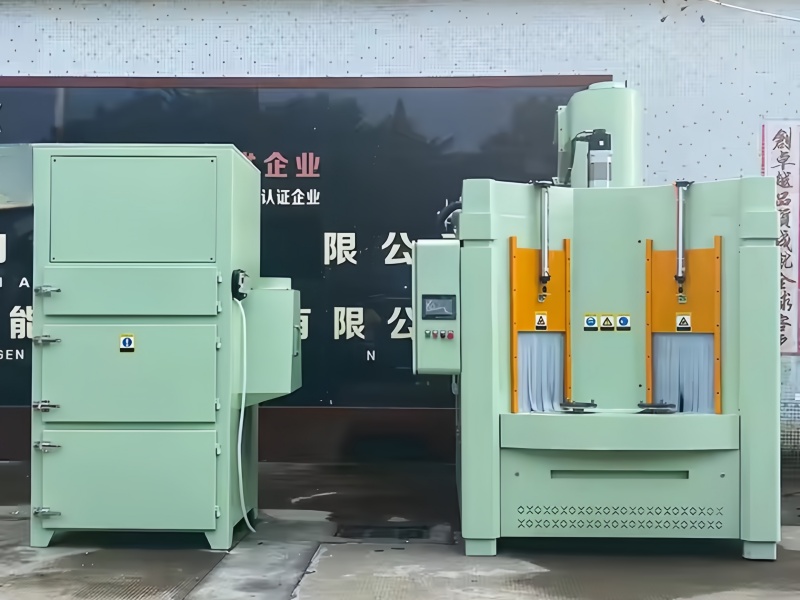

Machine Sandblast: An Overview

Sandblasting, also known as abrasive blasting, is a widely used industrial process that involves propelling abrasive materials at high speed onto a surface to clean, smooth, or prepare it for further treatment. This technique is highly effective for removing rust, old paint, and other contaminants, and it can also be used to create specific surface finishes。

Key Components of Sandblasting Equipment

1.Air Compressor: Provides the high-pressure air needed to propel the abrasive media。

2.Blast Pot or Pressure Vessel: Holds the abrasive media and regulates its flow into the airstream。

3.Blast Hose: Transports the abrasive-laden air from the blast pot to the nozzle。

4.Blast Nozzle: Directs the high-velocity stream of abrasive media onto the target surface。

5.Moisture Filter/Separator: Removes moisture from the compressed air to prevent clumping of the abrasive media。

6.Protective Gear: Includes respirators, blast hoods, gloves, and protective clothing to ensure operator safety。

Sandblasting Process

1.Preparation: Choose the appropriate abrasive media (e.g., sand, steel grit, glass beads) and ensure all equipment is functioning properly。

2.Equipment Setup: Connect the sandblasting machine to an air compressor and ensure a dry air supply. Assemble hoses and attach the nozzle。

3.Activation and Blasting: Adjust the air pressure according to the surface being treated and activate the air compressor to start the blasting process。

4.Application: Use the abrasive media to achieve the desired surface finish, such as cleaning, smoothing, or etching。

Main Applications

1.Surface Cleaning: Removes rust, paint, and oxidation from metal, wood, and concrete surfaces。

2.Surface Preparation: Prepares surfaces for painting, coating, or welding by creating a clean and roughened surface。

3.Specialized Applications: Used for creating patterns on glass or etching designs on metal surfaces。

Benefits of Sandblasting

1.Versatility: Suitable for a wide range of materials, including metals, glass, wood, and stone。

2.Efficiency: Reduces labor and maintenance costs while improving surface adhesion for coatings。

3.Durability: Enhances the longevity of coatings by creating a clean and roughened surface。

4.Cost-Effectiveness: Offers a balance of affordability and performance。

Safety Considerations

1.Respiratory Protection: Operators must wear appropriate protective gear to avoid inhaling abrasive particles。

2.Moisture Control: Ensure a dry air supply to prevent clumping of the abrasive media。

3.Proper Maintenance: Regularly inspect and maintain equipment to ensure optimal performance and safety。

Sandblasting is a powerful and versatile technique used across various industries for surface preparation and cleaning. Its effectiveness, combined with modern safety measures and equipment, makes it an indispensable tool for many applications。