Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

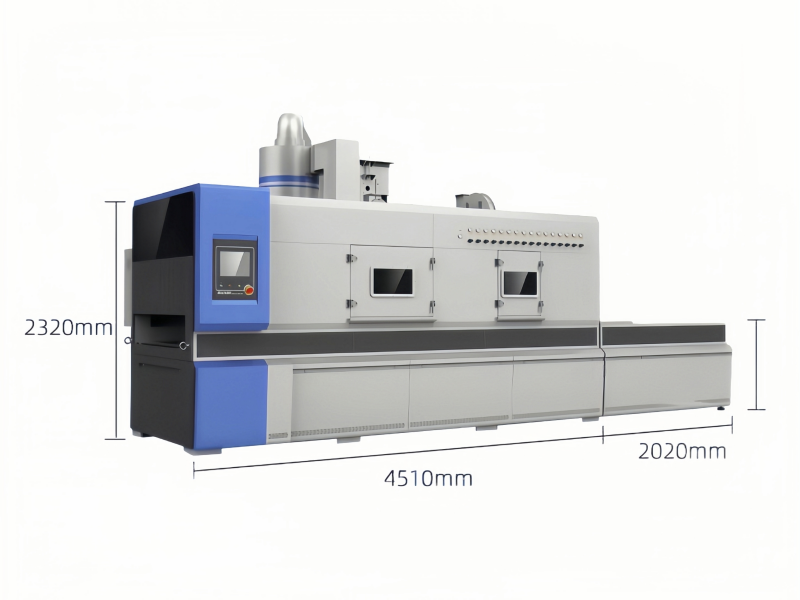

1.Name:Roller Conveyor Sand Blasting Machine

2.Model:MZ

3.Operation Way: Automatic

Roller Conveyor Sand Blasting Machine: An In-Depth Overview

Definition

A Roller Conveyor Sand Blasting Machine is an industrial device designed for the surface treatment of flat or long workpieces, such as steel plates, profiles, pipes, or beams. It uses a roller conveyor system to transport the workpieces through a blasting chamber where abrasive media are propelled at high velocity to clean, descale, derust, and prepare surfaces.

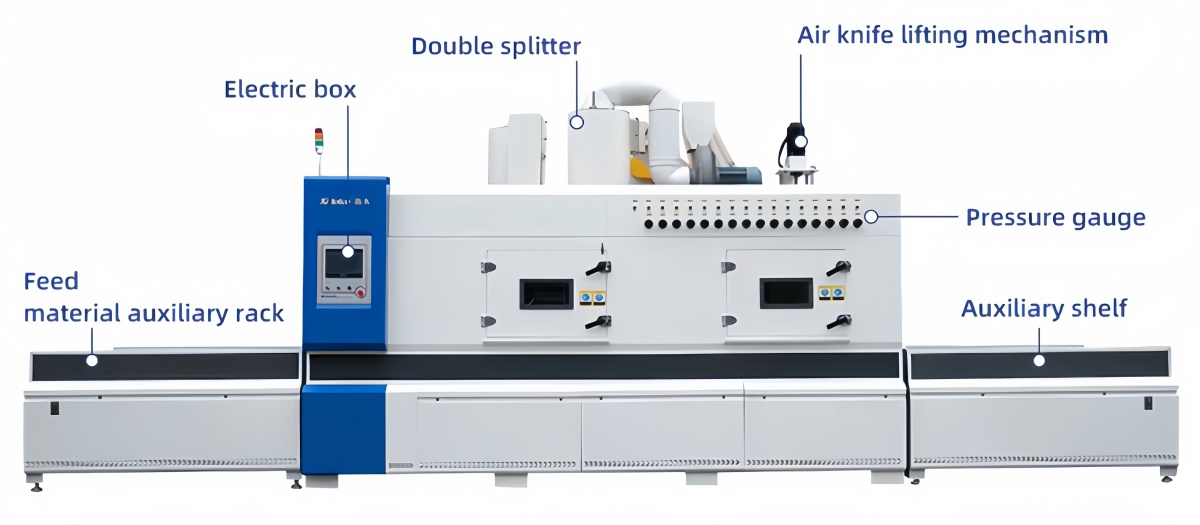

Components

1.Roller Conveyor System:

(1) Rollers: Made of high-grade wear-resistant materials (e.g., manganese steel) to withstand abrasive blasting. Rollers in the blast zone have additional dust seals to prevent abrasive media from entering the bearings.

(2) Drive Mechanism: Consists of sprockets and chain drives to rotate the rollers. The transport speed can be regulated using a variable frequency drive unit.

2.Machine Housing:

(1) Entrance and Exit Sections: Equipped with rubber screens or curtains to seal the machine and prevent abrasive media from escaping.

(2) Blasting Chamber: Constructed with wear-resistant manganese steel cladding or interchangeable wear plates to protect against abrasive impacts.

3.Blasting Wheels:

Strategically positioned to achieve complete coverage of the workpiece. The number of wheels can vary from 4 to 16, depending on the machine size and application.

4.Media Transport and Recovery System:

(1) Hoppers and Screw Conveyors: Collect and transport used abrasive media from the blast zone to the bucket elevator.

(2) Bucket Elevator: Transports the abrasive media from the bottom to the top of the machine for recycling.

(3) Media Cleaner: Separates dust and fines from the abrasive media, ensuring only clean media are reused.

(4) Storage Silo: Temporarily stores the cleaned abrasive media before it is reused.

5.Cleaning Section:

Roller Brushes and Air Blowers: Remove residual dust and abrasive media from the workpiece after blasting. The height of the brushes can be adjusted to accommodate different workpiece heights.

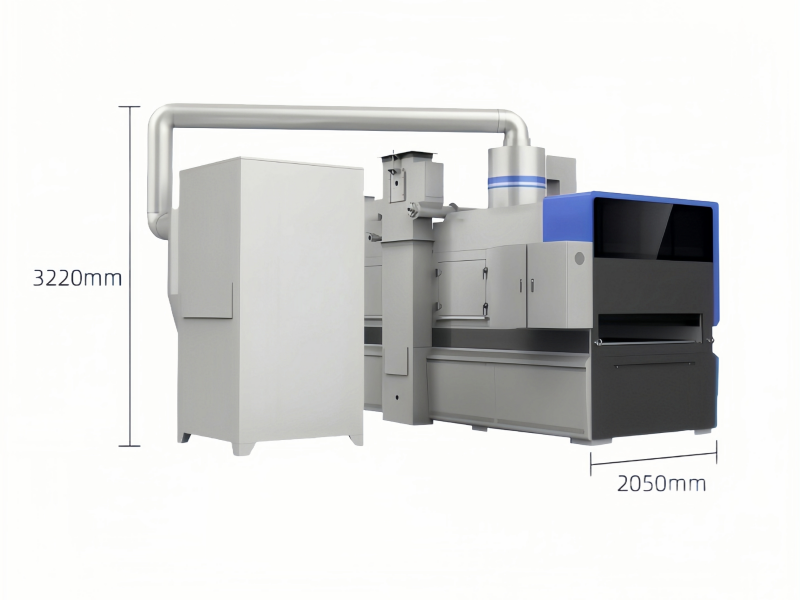

6.Dust Collection System:

Ensures a clean working environment by capturing and filtering dust generated during the blasting process.

Function and Operation

The Roller Conveyor Sand Blasting Machine operates by loading workpieces onto the roller conveyor at one end. The workpieces are then transported through the blasting chamber, where they are exposed to a high-velocity stream of abrasive media propelled by the blasting wheels.

The workpieces are blasted on all sides to ensure thorough cleaning and surface preparation. After blasting, the workpieces pass through the cleaning section to remove any residual dust and abrasive media.

Uses

1.Surface Cleaning and Descaling: Removes rust, scale, and contaminants from steel plates, profiles, and pipes.

2.Paint and Coating Removal: Prepares surfaces for repainting or other treatments.

3.Surface Preparation: Improves surface finish and increases paint adhesion.

4.Deburring and Finishing: Smooths rough edges and improves surface quality.

Advantages

1.High Throughput: Continuous blasting process ensures high production rates.

2.Uniform Coverage: Strategically positioned blasting wheels ensure all surfaces are treated.

3.Low Maintenance: Durable construction and easy access for maintenance reduce downtime.

4.Customizability: Machines can be tailored to specific workpiece sizes and production requirements.

5.Environmental Protection: Efficient dust collection and media recycling systems minimize environmental impact.

Conclusion

The Roller Conveyor Sand Blasting Machine is a versatile and efficient solution for surface treatment in various industries. Its ability to handle large and heavy workpieces, combined with high throughput and customizable options, makes it an ideal choice for applications ranging from steel descaling to surface preparation for painting. The machine’s design ensures minimal maintenance and environmental impact, further enhancing its value in industrial settings.