Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

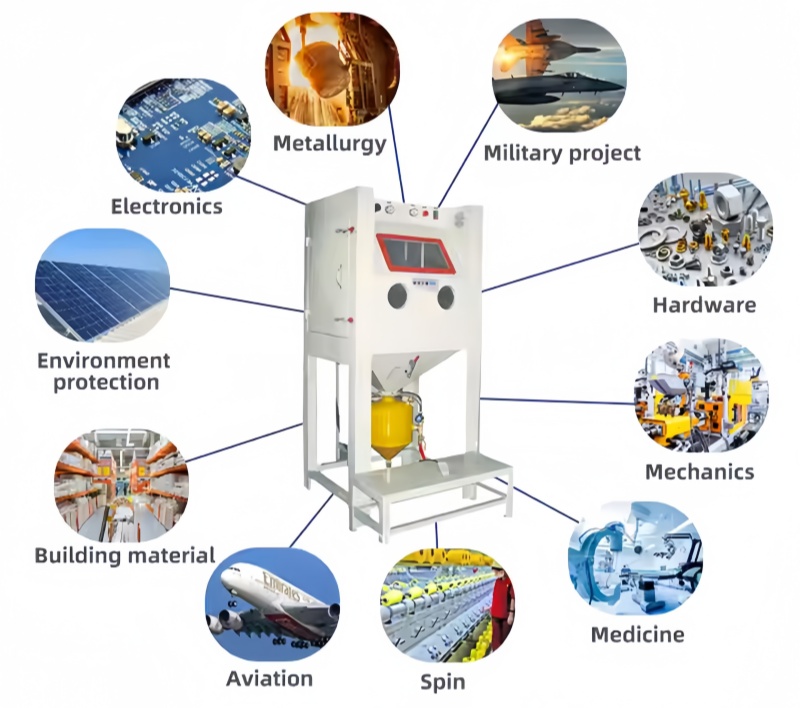

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:High Pressure Sand Blasting Machine

2.Model:MS

3.Operation Way: Manual

High Pressure Sand Blasting Machine: An In-Depth Overview

Definition

A High Pressure Sand Blasting Machine is a specialized industrial tool designed to clean, strip, and prepare surfaces using a combination of high-pressure air and abrasive media. This machine is capable of delivering abrasive particles at extremely high velocities, making it highly effective for heavy-duty applications.

Components

1. Air Compressor: Provides the necessary high-pressure air to propel the abrasive media.

2. Pressure Tank: Stores the abrasive media and maintains the required pressure.

3. Blast Hose: Transfers the high-pressure abrasive mixture from the tank to the nozzle.

4. Blast Nozzle: Directs the high-velocity stream of abrasive media onto the surface.

5. Control System: Includes valves and gauges to regulate pressure and flow.

6. Safety Equipment: Essential for operator protection, including blast suits, gloves, and respiratory protection.

7. Optional Accessories: Some models feature additional components like moisture traps, pressure regulators, and various nozzle sizes for different applications.

Working Principle

The High Pressure Sand Blasting Machine operates by mixing high-pressure air with abrasive media inside the pressure tank. When the operator activates the control valve, the high-pressure mixture is propelled through the blast hose and out of the nozzle. The abrasive particles strike the surface at extremely high velocities, effectively removing contaminants, paint, rust, and other materials.

Uses

High Pressure Sand Blasting Machines are used in a variety of industrial applications, including:

1. Surface Cleaning: Removes rust, scale, and contaminants from metal surfaces.

2. Paint and Coating Removal: Prepares surfaces for repainting or other treatments.

3. Deburring and Descaling: Smooths rough edges and removes scale from metal parts.

4. Surface Preparation: Creates a clean, uniform surface for welding, bonding, or coating.

5. Maintenance and Repair: Ideal for heavy-duty applications in automotive, shipyard, railway, and construction industries.

Advantages

1.High Efficiency: Delivers abrasive media at high velocities, resulting in faster and more effective cleaning and stripping.

2.Versatility: Can handle a wide range of abrasive media, including sand, glass beads, steel grit, and more.

3.Portability: Many models are designed to be mobile, allowing for easy transport between job sites.

4.Consistency: Provides a consistent and uniform finish across large surfaces.

5.Safety: With proper safety equipment, reduces the risk of dust inhalation and other hazards.

6.Durability: Built with heavy-duty materials to withstand harsh industrial environments.

Comparison with Other Sand Blasting Machines

1.Pressure vs. Siphon-Feed: High-pressure machines are more efficient and faster than siphon-feed systems, which rely on suction to draw abrasive media into the airstream.

2.Wet vs. Dry Blasting: High-pressure sand blasting machines are typically dry, making them more suitable for heavy-duty applications where water is not needed. However, wet blasting machines offer dust suppression and are better for delicate surfaces.

Conclusion

The High Pressure Sand Blasting Machine is a powerful and versatile tool for surface preparation and cleaning. Its ability to deliver abrasive media at high velocities makes it highly effective for heavy-duty applications. Whether used for rust removal, paint stripping, or surface preparation, a high-pressure sand blasting machine offers significant advantages in terms of efficiency, consistency, and versatility. As industrial processes continue to demand more efficient and effective surface treatment solutions, high-pressure sand blasting machines remain a crucial tool in many industries.

Sandblasting chamber

The sandblasting chamber is made and welded into one piece with high-quality carbon steel plates that are treated by our shot blasting machine, our sand blasting machines are sturdy and highly durable for frequent sand blasting under nasty working environment.

Pressure tank system (only for high pressure sandblasting machine)

The system is installed with 1 peach-type pressure tank to increase steel grit fluidity. The upper part is connected with a pneumatic butterfly valve and a storage bin. The pneumatic valve is closed during the blasting operation and opened to input shot at the end of the blasting.

Recycling pipes (only for siphonic sandblasting machine)

After cyclone separation, good abrasives are heavier and fall to the bottom of the separator and be sucked to the sand conveyor pipe to recycle usage.

Separator system (only for siphonic sandblasting machine)

Cyclone separator is used to separate good shots, broken shots and dust. Shots, In the cyclone separator and under the action of centrifugal wind, good shots are heavy to fall to the bottom of the separator but tiny broken shots and dust are much lighter to be sucked out of the separator.

Pressure Regulation Valve

It can control the fixed outlet pressure of the main valve, so that the outlet pressure of the main valve won’t change with the pressure or the volume of inlet and outlet air.

Dedusting System: (cartridge filter)

a.Most of good abrasive is separated and collected in the cyclone separator. The escaped air & dust mixture goes into the cartridge filter in which dust is blocked by the filter inside and fresh clean air goes through the filter to go out.

b.electromagnetic pulse technology is used to separate the dust from the filter and dust goes down to the collect storage cabinet due to its gravity.

c.This dedusting system works to ensure that the dust emission is lower than 50mg/m³.

Name | Manual siphon sandblasting machine | High Pressure sandblasting machine | Turntable sandblasting machine | ||

Model | MS-6050 | MS-9060 | MS-9090 | MS-9060F | MS-1305 |

Air pressure type | Suction Type | High Pressure | |||

Abrasive | Glass sand、ceramic sand、Brown corundum、white corundum etc. | Glass shot/sand、ceramic shot /sand、Brown corundum、white corundum etc. | |||

Application | Hardware、electronics、mould and some small workpiece surface rust cleaning ,Degreasing,deburring,descaling ,cleaning the surface paint,currently widely used for spraying,electroplate pretreatment process to enhance the coating (plating) surface Adhesion. | ||||

Chamber Size (L*W*H )mm | 600*500*500 | 900*600*600 | 900*900*700 | 900*600*600 | 1500*1500*1400 |

Workpiece Size(L*W*H )mm | 400*400*200 | 550*450*230 | 600*600*300 | 550*450*230 | 1200*1200*600 |

Dust collector type | Electromagnetic pulse dust collector (filter cartridge type) | ||||

Dedusting Fan | 550W 220V/50hz | 750W 220V/50hz | 4KW 380V/50HZ | ||

Floodlight | 50W-LED(1 set) | ||||

Floodlight | 6mm | 8mm | |||

Cyclone Separator | 50W-LED(1 set) | ||||

Foot Switch | 1 PC | ||||

Solenoid Valve | 1 PC | ||||

Pressure Regulation Valve | 1 PC | ||||

Pulse valve | 1 PC | ||||

Filter +Automatic Emission | 1 set | ||||

Pressure | 5-8KG/m3 | ||||

Cotton Glove | 1 Pair | ||||

Low-Voltage Apparatus | CHINT | ||||

Power | AC220V | ||||

Total Power | 0.6KW | 0.8KW | 5.6KW | ||

Total Weight | 0.2T | 0.3T | 0.38T | 0.42T | 1.56T |

Equipment Dimension(L*W*H )mm | 700*1000*1600 | 1334*1000*2102 | 1000*1500*1700 | 1000*1000*2100 | 4608*3220*2644 |