Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Dustless Water Sandlaster Machine

2.Model:MZ

3.Operation Way: Manual

Dustless Water Sandblasting Machine: An In-Depth Overview

Definition

A Dustless Water Sandblasting Machine is a specialized industrial tool designed to clean, strip, and prepare surfaces using a combination of water and abrasive media. Unlike traditional dry sandblasting methods, this machine incorporates water to significantly reduce dust emissions, making the process safer and more environmentally friendly.

Components

1.Water Reservoir: Stores and supplies water to mix with the abrasive media.

2.Abrasive Hopper: Holds the abrasive material, such as sand, glass beads, or other media.

3.Mixing Chamber: Combines water and abrasive media to create a slurry.

4.High-Pressure Pump: Pressurizes the slurry mixture to ensure effective blasting.

5.Nozzle and Blast Gun: The nozzle directs the high-pressure slurry onto the surface, while the blast gun controls the flow and pressure.

6.Compressed Air System: Provides the necessary air pressure to accelerate the slurry through the nozzle.

7.Recycling System: Some models feature a recycling system to reuse the abrasive media, reducing waste and costs.

Working Principle

The Dustless Water Sandblasting Machine operates by mixing water and abrasive media in a mixing chamber. This mixture is then pressurized by a high-pressure pump and propelled through a nozzle using compressed air. The water in the slurry helps to suppress dust, making the process much cleaner and safer compared to traditional dry sandblasting. The slurry is directed onto the surface at high speed, effectively removing contaminants, paint, rust, and other materials.

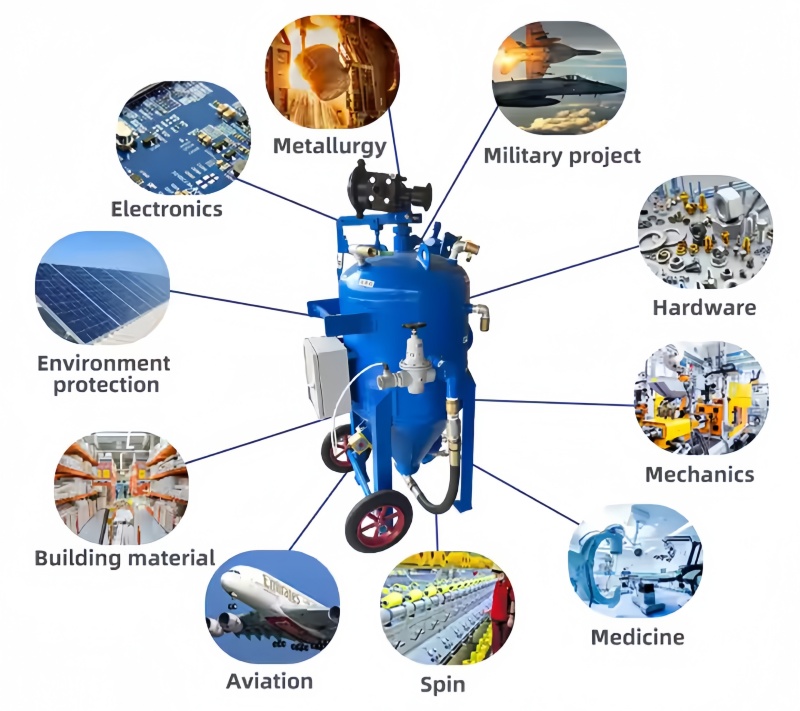

Applications

1.Surface Cleaning: Removes rust, paint, and contaminants from metal surfaces.

2.Paint Stripping: Efficiently strips old paint from various substrates, including metal, wood, and concrete.

3.Deburring and Descaling: Smooths rough edges and removes scale from metal parts.

4.Surface Preparation: Prepares surfaces for coating, bonding, or welding by creating a clean, uniform finish.

5.Restoration: Used in the restoration of historic buildings, monuments, and vehicles to remove old finishes without damaging the underlying material.

Advantages

1.Dust Suppression: The water in the slurry significantly reduces dust emissions, improving air quality and reducing the risk of respiratory issues for operators.

2.Safety: Lower dust levels also reduce the risk of fire and explosion, making the process safer in environments where flammable materials are present.

3.Environmental Friendliness: Reduces the amount of airborne particulates, minimizing environmental impact and compliance with air quality regulations.

4.Surface Protection: The water helps to cool the surface, reducing the risk of heat damage and static electricity buildup.

5.Precision and Consistency: Provides a more controlled and consistent finish compared to dry sandblasting.

6.Versatility: Suitable for a wide range of materials, including delicate surfaces that could be damaged by dry blasting.

7.Cost-Effective: The recycling system in some models reduces the need for frequent abrasive media replacement, lowering operational costs.

Conclusion

The Dustless Water Sandblasting Machine is a highly effective and environmentally friendly alternative to traditional dry sandblasting. Its ability to significantly reduce dust emissions while providing precise and consistent surface preparation makes it an ideal choice for a variety of industrial and restoration applications. As awareness of environmental and safety concerns grows, dustless water sandblasting is likely to become an increasingly popular method for surface treatment and preparation.

|

Model |

Capacity (CF) |

Continuous Time(min) |

External Dimensions(mm) |

Weight (kg) |

Pressure (Psi) |

|

MZ-150 |

1 |

15 |

H1240x800x900 |

120 |

30-150 |

|

MZ-225 |

2 |

30 |

H1400x760x910 |

140 |

30-150 |

|

MZ-500 |

5 |

60 |

H1560x1000x1080 |

220 |

30-150 |

|

MZ-800 |

8 |

90-120 |

H1800x1000x1080 |

240 |

30-150 |

|

Machine including |

|||||

|

1) 15m sandblasting hose:1pc 2) Boron carbide nozzle:1 pc 3) Pipe-clamping valve:1pc 4) Feeding hopper:1pc 5) Vibrator:1pc 6) Pressure regulating valve:1pc 7) Pressure reducing valve:1pc |

|||||