Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Automatic Rotary Table Sand Blasting Machine

2.Model:MZ

3.Operation Way: Automatic

Automatic Rotary Table Sand Blasting Machine: An In-Depth Overview

Definition

An Automatic Rotary Table Sand Blasting Machine is a specialized industrial device designed for the efficient surface treatment of small to medium-sized workpieces. It features an automated rotating table that holds multiple workpieces, allowing them to be blasted simultaneously from multiple angles. This machine is ideal for high-volume production environments where consistent and uniform surface treatment is required.

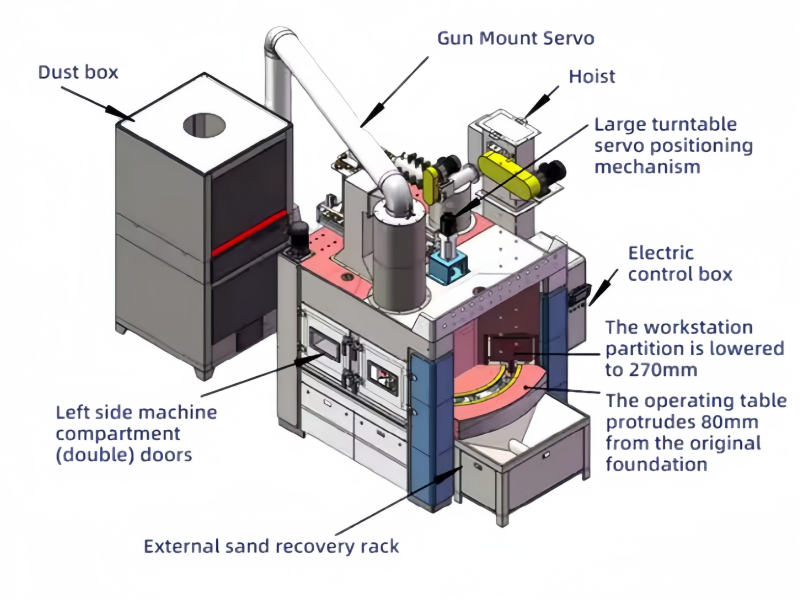

Components

1.Rotary Table:

(1) Table Surface: Typically made of wear-resistant materials, designed to hold multiple workpieces.

(2) Drive Mechanism: Ensures smooth and continuous rotation of the table. The speed can often be adjusted to match the specific requirements of the blasting process.

2.Blasting Chamber:

(1) Enclosure: A sealed chamber that contains the blasting process, preventing abrasive media and dust from escaping into the environment.

(2) Viewing Windows: Allow operators to monitor the blasting process without interrupting it.

3.Blasting Guns:

(1) Nozzles: Positioned around the rotary table to deliver high-velocity streams of abrasive media onto the workpieces.

(2) Control System: Regulates the flow and pressure of the abrasive media, ensuring consistent and uniform blasting.

4.Abrasive Media System:

(1) Hopper: Stores the abrasive media before it is fed into the blasting guns.

(2) Recycling System: Collects and recycles used abrasive media, reducing waste and operational costs.

5.Dust Collection System:

Filters and Fans: Capture and remove dust generated during the blasting process, maintaining a clean working environment and protecting the operator's health.

6.Control Panel:

(1) User Interface: Allows operators to adjust parameters such as rotation speed, blasting pressure, and cycle time.

(2) Safety Features: Includes emergency stop buttons and safety interlocks to ensure safe operation.

Working Principle

The Automatic Rotary Table Sand Blasting Machine operates by placing multiple workpieces on the rotating table. As the table rotates, the workpieces are exposed to high-velocity streams of abrasive media from the blasting guns positioned around the chamber. The rotation ensures that all sides of the workpieces are blasted uniformly. The used abrasive media are collected and recycled, while the dust is captured by the dust collection system.

Uses

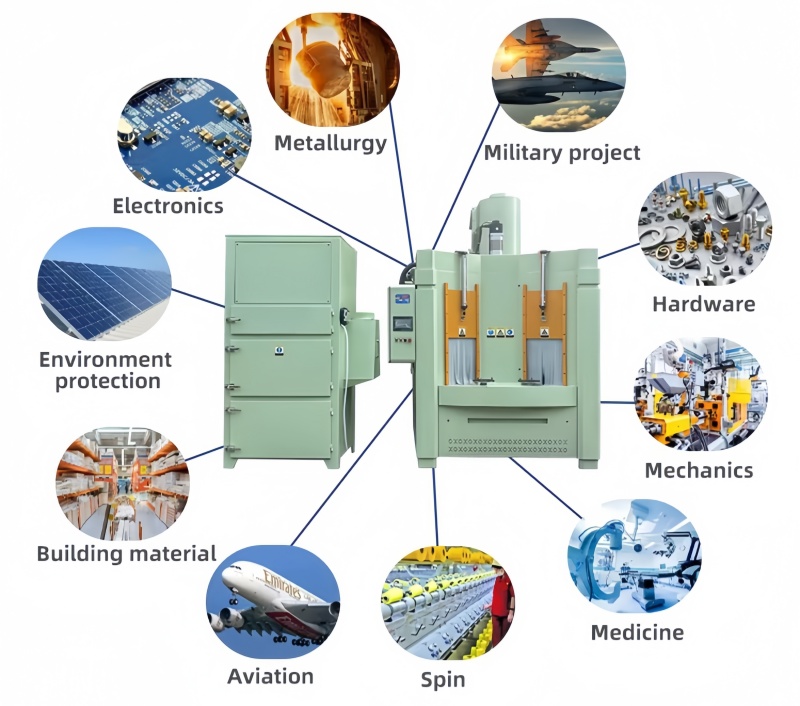

1.Surface Cleaning: Removes rust, scale, and contaminants from small to medium-sized parts.

2.Paint and Coating Removal: Prepares surfaces for repainting or other treatments.

3.Surface Preparation: Improves surface finish and increases paint adhesion.

4.Deburring and Finishing: Smooths rough edges and improves surface quality.

5.High-Volume Production: Ideal for industries that require consistent and uniform surface treatment for large quantities of parts.

Advantages

1.High Efficiency: Simultaneous treatment of multiple workpieces increases production rates.

2.Uniformity: Rotating table ensures consistent and uniform blasting on all sides of the workpieces.

3.Automation: Reduces the need for manual intervention, minimizing operator fatigue and improving consistency.

4.Safety: Enclosed blasting chamber and safety features protect operators from hazardous dust and abrasive media.

5.Cost-Effectiveness: Recycling system reduces the need for frequent abrasive media replacement, lowering operational costs.

6.Versatility: Suitable for a wide range of materials and applications, including metal, plastic, and composite parts.

7.Customizability: Can be tailored to specific production requirements, including table size, rotation speed, and blasting parameters.

Conclusion

The Automatic Rotary Table Sand Blasting Machine is a highly efficient and versatile solution for surface treatment in high-volume production environments. Its ability to treat multiple workpieces simultaneously, combined with uniform blasting and automated operation, makes it an ideal choice for industries requiring consistent and high-quality surface finishes. The machine’s design ensures safety, cost-effectiveness, and adaptability to various production needs, making it a valuable addition to any manufacturing facility.