Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Automated Sandblasting

2.Model:MZ

3.Operation Way: Automatic

Working Principle of Automated Sandblasting

Automated sandblasting machines operate by combining high-pressure air with abrasive materials to clean and prepare surfaces. The process involves the following steps:

Working Principle of Automated Sandblasting

Automated sandblasting machines operate by combining high-pressure air with abrasive materials to clean and prepare surfaces. The process involves the following steps:

1.Compressed Air Generation:

A compressor generates high-pressure air, which is then regulated to control the pressure and flow.

2.Abrasive Delivery:

The high-pressure air creates a negative pressure inside the blast gun, which draws abrasive material (such as steel shot, glass beads, or sand) from a storage tank. The abrasive is then propelled through the blast gun.

3.Surface Impact:

The abrasive material is accelerated and ejected from the blast gun, hitting the workpiece surface at high speed. This impact force removes contaminants, rust, paint, and other impurities while increasing surface roughness for better coating adhesion.

4.Material Recovery and Recycling:

After impacting the surface, the abrasive material is collected and separated from waste material. The reusable abrasive is then recycled back into the storage tank for further use.

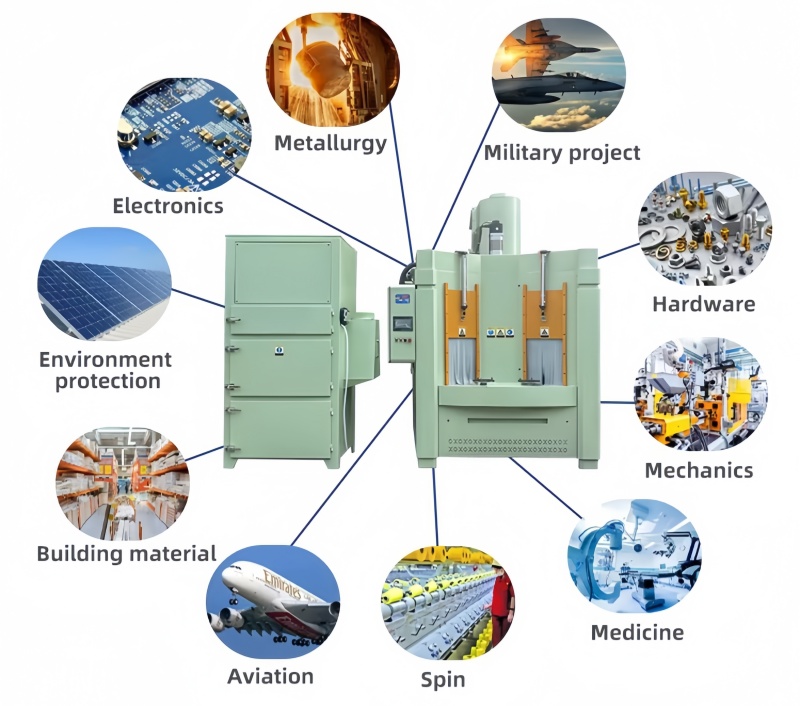

Applications of Automated Sandblasting

Automated sandblasting machines are used across various industries for their efficiency, precision, and ability to handle large volumes of workpieces. Key applications include:

1.Automotive Industry:

Used for removing paint, rust, and other contaminants from metal parts, ensuring surfaces are clean and smooth before painting or coating.

2.Aerospace Industry:

Critical for maintenance, repair, and overhaul (MRO) of components. Automated systems provide precise surface preparation, removing oxides and old coatings without damaging the underlying material.

3.Manufacturing Industry:

Employed for cleaning molds, dies, and preparing surfaces for welding or bonding.

These systems handle large volumes of workpieces with consistent quality, improving throughput and reducing downtime.

4.Construction and Shipbuilding:

Used to prepare concrete surfaces, clean steel structures, and remove coatings from various materials. In shipbuilding, they maintain hull integrity by removing marine growth and old paint

5.Glass and Stone Processing:

Used for engraving and decoration. By adjusting the type and particle size of abrasives and the pressure and angle of the spray, unique textures and patterns can be created on glass and stone surfaces.

Advantages of Automated Sandblasting

1.Improved Safety:

Automated systems reduce worker exposure to hazardous environments, minimizing health risks associated with inhalation of abrasive particles and dust.

2.Enhanced Precision:

Robotic arms and programmable systems provide precise control over the sandblasting process, ensuring consistent results and reducing the risk of damaging the workpiece.

3.Higher Quality:

Automated systems produce uniform surface finishes, meeting high-quality standards and ensuring better adhesion of coatings.

4.Increased Productivity:

These systems can operate continuously without breaks, optimizing production processes and reducing lead times.

5.Cost Savings:

While the initial investment can be significant, the long-term savings in labor, improved productivity, and reduced material waste make automated sandblasting a worthwhile investment.

Choosing the Right Automated Sandblasting System

Selecting the appropriate automated sandblasting system involves considering several factors:

1.Type of Surface Preparation:

Different applications may require varying levels of abrasiveness, precision, and coverage. For example, delicate aerospace components need fine-tuning to avoid damage, while large industrial parts benefit from robust systems.

2.Industry-Specific Requirements:

Each industry has unique demands regarding surface finish standards, material handling, and safety regulations. For instance, the automotive industry requires high throughput and precise finishes, while the aerospace industry demands exceptional precision and consistency.

3.Robotic System Capability:

Modern systems come with advanced features such as programmable robotic arms, real-time monitoring, and adaptive control systems. These features enable dynamic adjustments for optimal performance.

4.Scalability and Flexibility:

The ability to scale up or reconfigure the system for different tasks provides long-term benefits. Modular components and software upgrades can enhance versatility.

Cost:

Conducting a thorough cost-benefit analysis helps justify the investment, considering both direct and indirect savings.

Reliable Partner:

Choosing a partner that offers comprehensive support services, including training and maintenance, ensures smooth implementation and maximizes the system’s benefits.

Conclusion

Automated sandblasting technology has revolutionized surface treatment processes, offering significant improvements in efficiency, precision, and safety. By selecting the right system and partner, industries can achieve high-quality surface finishes, reduce operational costs, and enhance overall productivity.