Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Automatic Suspended chain through shot blasting machine +Powder coating Line : 1 set

2.The Max. parts size: L2100*W300*H1300mm

3.The line speed: 2m/min

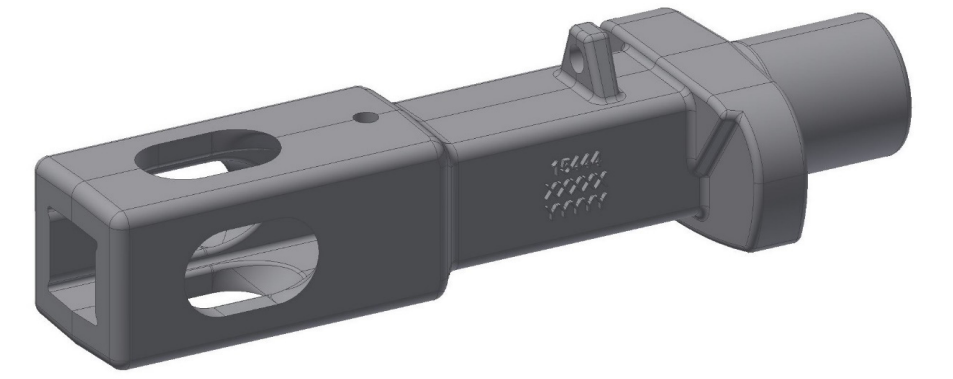

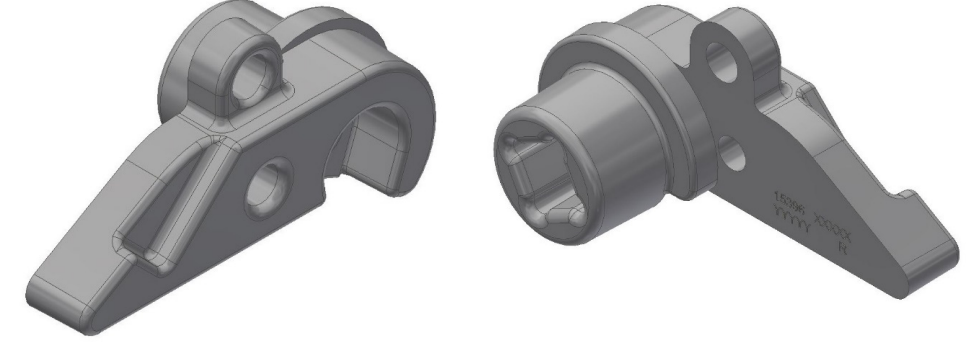

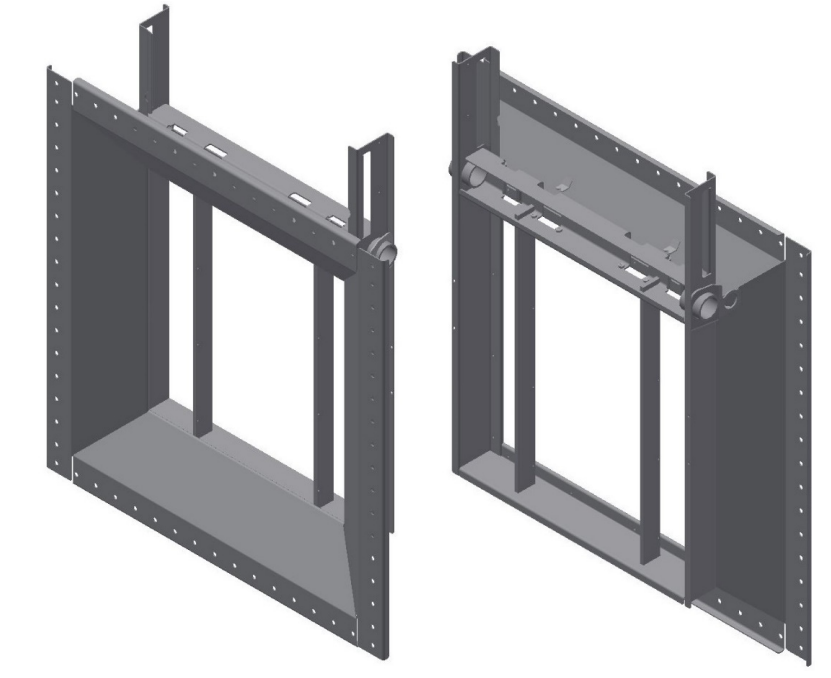

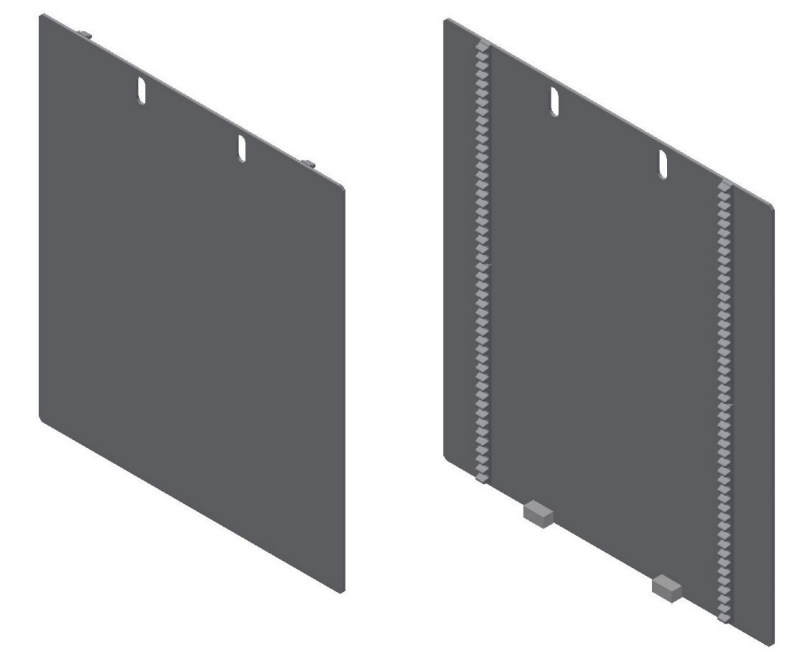

It is applied to gate parts shot blasting and powder coating

Shot Blasting Machine+Powder Coating Line Introduction:

1. Design Basis and Parameter

(1) Product Name: Welded Parts

(2) Workpiece material; Carbon steel, with oil stains on the surface but no rust

(3) Comprehensive hanging size of the workpiece: L2100*W300*H1300mm (Max.)

(4) The hanging weight of the workpiece group: no more than 125kg

(5) Suspended conveyor chain: QXT-300.100 closed chain

(6) Process chain speed: 2.0m/min (adjustable by frequency conversion from 1.5 to 2.5m/min).

(7) Heating energy: Natural gas

(8) Tap water: Water supply pressure 2 to 4 kg/cm ² (meeting national tap water standards)

(9) Power supply: The voltage is: 240V± 15%, three-phase four-wire system, 60HZ

(10) Compressed air: 4 to 6kg/cm ², oil content: ≤0.1ppm, water content: ≤1.3g/m ³

(11) Available space for the equipment: 16m W x 52.5m L x 8m H

(12) Other indicators

① Electricity: 240V±10%,60HZ. Power supply mode: Three-phase four-wire system.

② Gas: Calorific value: Natural gas ~ 8500Kcal/Nm3.

2. Coating Process Design

(1)Powder coating process flow parameters:

NO. | Name | Process Method | Temperature | Time | Remarks |

1 | Loading | Manual | |||

2 | Shot blasting | Shot Blasting Machine | |||

3 | Wash with hot water | Spray | 45-50℃ | 30S | Plate heating outside the tank, equipped with a complete tank liquid monitoring system |

4 | Pre-degreasing | Spray | 45-50℃ | 60S | |

5 | Main degreasing | Spray | 45-50℃ | 120S | Plate heating outside the tank, equipped with a complete tank solution monitoring system, overflows to pre-degreasing |

6 | Water-washed 1# | Spray | Room temperature | 36S | Overflow drainage ditch |

7 | Water-washed 2# | Spray | Room temperature | 36S | Overflow into water washing 1 |

8 | Fresh water is sprayed directly | Spray | Room temperature | Single row | Flow into the water wash 2 |

9 | Surface conditioning | Spray | Room temperature | 60S | Overflow drainage ditch |

10 | Phosphating | Spray | 35-45℃ | 180S | The external plate heat exchanger is equipped with a complete tank liquid monitoring system |

11 | Fresh pure water sprayed directly | Spray | Room temperature | Single row | |

12 | Water-washed 3# | Spray | Room temperature | 30S | Overflow drainage ditch |

13 | Water-washed 4# | Spray | Room temperature | 30S | Overflow into the water washing 3 |

14 | Pure water-washed 1 | Spray | Room temperature | 30S | Overflow into the water washing 4 |

15 | Fresh pure water sprayed directly | Spray | Room temperature | Single row | Flow into pure water 1 |

16 | Dripping water + blowing water | Automatic | Room temperature | 7min | Reserve manual water blowing before entering the drying furnace |

17 | Moisture drying furnace | Hot air circulation | 120-16o℃ | 15min | Direct heating of natural gas |

18 | Natural cooling | R.T | 12min | ||

19 | Powder spraying | Reciprocating machine + hand supplement | R.T | Large cyclone quick color change, automatic gun + reserved manual re-spray position | |

20 | Powder curing furnace | Hot air circulation | 180-220°C | 30min | Direct heating of natural gas,Adjustable temperature |

21 | Natural cooling | R.T | 17min | ||

22 | Unloading | Manual | R.T |

(2)Process Description

① In the process design, the rust removal process for going online is not taken into account, and the rust is resolved before going online.

② Pre-degreasing, main degreasing and ceramizing adopt medium-temperature processes. The heating method is indirect heating outside the hot water tank, and the secondary heating time is less than 45 minutes.

③ To save water, all water washing processes adopt multi-stage counter-flow technology. Among them, the pre-degreasing, degreasing and ceramizing tanks are equipped with mixed-flow stirring tubes to prevent the sedimentation of the tank solution.

④ Powder coating adopts an automatic electrostatic spraying process to enhance the powder coating rate.

⑤ The powder spraying adopts a large cyclone two-stage recovery system, with automatic spraying by a reciprocating machine, and powder is sprayed on both sides and the front.

3.Equipment composition and performance description

(1) Coating line: The production line adopts the QXT-300.100 chain conveyor production line, mainly consisting of the following parts: shot blasting machine, pretreatment section, powder spraying section, moisture drying section, powder curing section, conveying system, and auxiliary equipment of the production line.

(2) Pretreatment section: A 10-station cleaning machine is adopted, mainly consisting of a process tank body, a closed shed body, a tank liquid circulation filtration and spray system, a tank liquid heating system, a maintenance ladder, an exhaust system, a water supply and drainage pipeline system, a liquid level control system, an automatic metering pump feeding system, etc.

(3) Moisture drying section: One bridge-type moisture drying furnace is adopted. The drying furnace is mainly composed of a heat preservation room body, a direct gas heating system and other parts.

(4) Powder spraying section: The powder spraying section mainly consists of a powder spraying chamber, powder spraying equipment, an automatic powder spraying system, a large cyclone two-stage recovery system, a powder room refrigeration and air supply system, isolation rooms, etc.

(5) Powder curing section: One bridge-type powder curing furnace is adopted. The drying furnace is mainly composed of a heat preservation room body, a direct gas heating system and other parts.

(6) Wastewater treatment system: The internal collection tank and transfer pipeline of the workshop are the responsibility of buyer. The wastewater treatment station is also the responsibility of Buyer. MIZHI is responsible for the configuration of transfer pumps in the water accumulation pool. The pre-treatment sewage is discharged through pipelines to the centralized wastewater temporary storage pool and then transferred to the wastewater treatment station through the transfer pump provided by Buyer. No separate sub-item drainage ditches are set up.

(7) Conveying system: It adopts the air QXT300.100 chain conveying and is controlled by variable frequency speed regulation and dual drive, featuring a high degree of automation.

(8) Production line supporting equipment: including hot water boilers, pure water units, primary hangers, etc.

(9) Electrical control system: To enhance the automation level of the production line and the scientific management, the production line adopts a PLC control system, which consists of an upper computer central control system, centralized control, and on-site control, among other components.

Main equipment details list

(1) Shot blasting machine 1 Set

(2) Pretreatment system 1 Set

(3) Moisture drying system 1 Set

(4) Suspended conveying system 1 Set

(5) Automatic powder spray chamber system 1 Set

(6) Automatic powder curing system 1 Set

(7) Powder room isolation room 1 Set

(8) Pure water system 1 Set

(9) Hot water boiler heating system 1 Set

(10) Electrical control system 1 Set

(11) Safety supervision and explosion-proof system 1 Set

(12) Air conditioning system (fresh air - adjustable temperature) 1 Set

4.It is used to gate parts: