Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

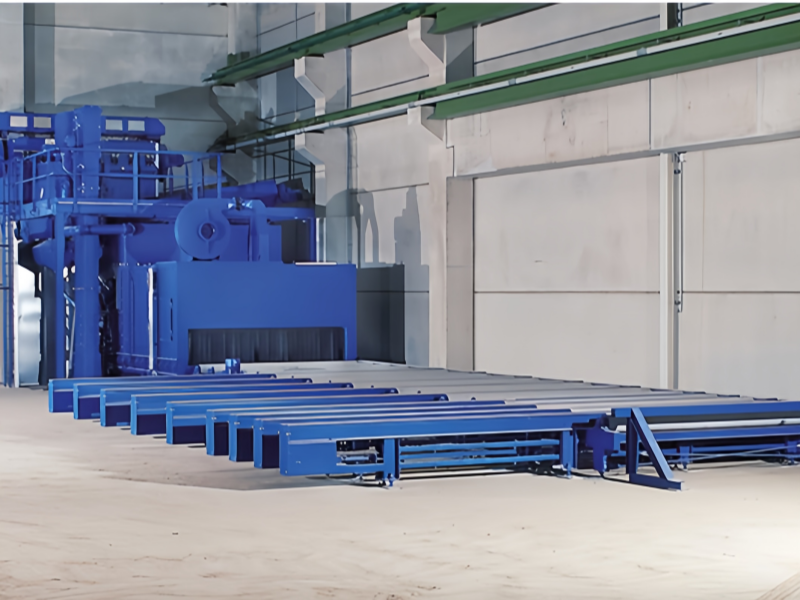

Steel Plate Shot Blasting Machine: A Comprehensive Guide

In the metal processing and surface treatment industries, the Steel Plate Shot Blasting Machine is a crucial piece of equipment. Here's a detailed overview:

Definition

The Steel Plate Shot Blasting Machine is a specialized industrial machine designed for the surface treatment of steel plates. It uses centrifugal force to propel abrasive media, such as steel shot or chilled iron shot, at high speeds onto the steel plate surface. This process effectively removes impurities and enhances the surface quality of the steel plate.

Functions

1.Surface Cleaning: Removes rust, oxide scales, mill scale, and contaminants from the steel plate surface. This prepares the steel for processes like painting, coating, or welding.

2.Surface Strengthening: The shot blasting process creates compressive stresses on the steel plate surface, enhancing its fatigue strength and resistance to stress corrosion cracking.

3.Surface Texturing: Produces a uniform and controlled surface roughness on the steel plate. This improves the adhesion of coatings or other materials applied afterward.

Applications

1.Shipbuilding Industry: Used for processing steel plates used in ship construction. Ensures the steel plates are clean and properly prepared for welding and coating.

2.Construction Sector: Applied to steel plates used in building construction, such as those used in bridges and high - rise buildings. This ensures the longevity and safety of the structures.

3.Heavy Machinery Manufacturing: Used for processing steel plates used in the production of heavy machinery. This improves the surface quality and durability of the machinery.

4.Metal Processing Industry: Applied to steel plates of various sizes and thicknesses to enhance their surface conditions before further fabrication.

Operating Procedure

1.Pre - operation Preparation: Check the machine to ensure it is in good working condition. Load the steel plates onto the machine's transportation system and secure them properly.

2.Start the Machine: Turn on the power and initiate the shot blasting process. The abrasive media will be propelled onto the steel plate surface by the spinning blast wheels.

3.Adjustment: Depending on the steel plate's thickness, size, and required surface finish, adjust parameters such as the blasting time, abrasive flow rate, and blast wheel speed.

4.Completion and Cleaning: Once the shot blasting is completed, turn off the machine and unload the steel plates. Clean off any residual abrasive from the steel plates and the machine.

Advantages

1.High - Efficiency Cleaning: Can quickly and thoroughly remove contaminants from large steel plates, significantly improving cleaning efficiency compared to manual methods.

2.Uniform Processing: The mechanical operation ensures consistent shot blasting results across the entire surface of the steel plate, achieving a uniform surface quality.

3.Enhanced Cleaning Quality: The high - speed bombardment of abrasive media effectively removes even the most stubborn contaminants, providing a high - quality surface finish.

4.Customizable Process: Parameters can be adjusted according to different steel plate specifications and requirements, offering flexibility in processing various types of steel plates.

Disadvantages

1.High Equipment Cost: The initial investment for purchasing and installing a steel plate shot blasting machine is relatively high, which may be a barrier for some small - scale enterprises.

2.Complex Operation and Maintenance: The machine has a relatively complex structure and operating principles. Operators need specialized training to master its operation and maintenance. Additionally, regular maintenance and timely replacement of worn - out parts are required to ensure its proper functioning.

3.Noise and Dust Generation: The shot blasting process may produce noise and dust, necessitating effective soundproofing and dust - collection measures in the operating environment.

Maintenance and Care

1.Daily Cleaning: Clean the machine's exterior and interior after each use to remove residual abrasive and contaminants. Clean the filters of the dust - collection system to ensure effective dust removal.

2.Regular Inspection: Periodically check the wear and tear of blast wheels, abrasive valves, and conveyor belts. Replace worn - out parts promptly to prevent equipment failures.

3.Lubrication: Apply lubricants to the machine's bearings, gears, and other moving parts as per the manufacturer's recommendations. This reduces friction and extends the service life of components.

4.Storage: When the machine is not in use for an extended period, store it in a dry and well - ventilated area. Cover it with a protective cover to prevent dust and moisture from affecting its performance.

By understanding the Steel Plate Shot Blasting Machine in depth, businesses can better assess its suitability for their specific needs and make informed decisions about its use and maintenance. This helps maximize the machine's benefits in industrial steel plate processing applications and improve the quality and efficiency of production processes.