Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

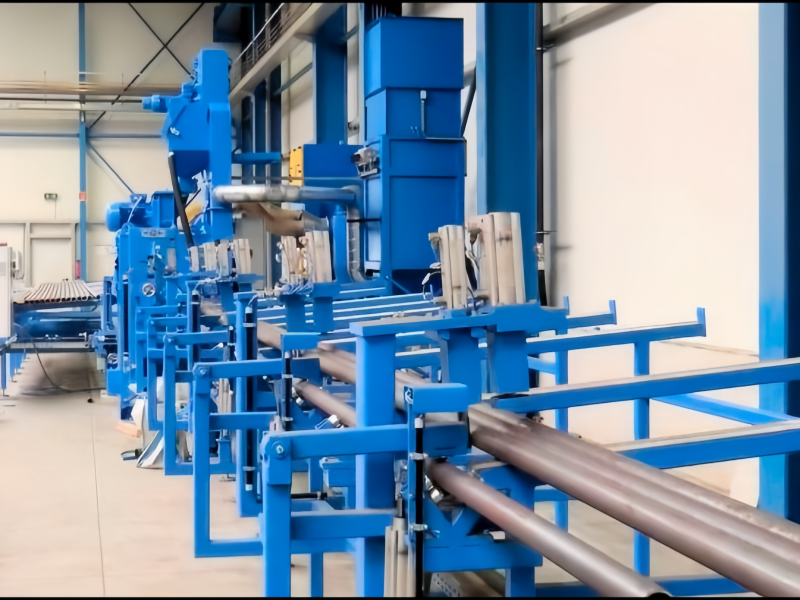

What is Steel Pipe Outer Wall Shot Blasting Machine with Roller Conveyor?

A Steel Pipe Outer Wall Shot Blasting Machine with Roller Conveyor is a specialized industrial device designed to clean and treat the exterior surfaces of steel pipes through shot blasting. This machine is widely used in industries such as steel manufacturing, construction, and shipbuilding to remove rust, scale, and other contaminants from steel pipes, preparing them for further processing like welding, painting, or coating.

Key Features

1.Efficient Surface Cleaning:

The machine uses high-speed blast wheels or nozzles to propel abrasive media (such as steel shot or grit) onto the outer surface of the steel pipes, effectively removing rust, scale, and other contaminants.

2.Automated Conveyor System:

Equipped with a roller conveyor system that transports the steel pipes through the blast chamber. The rollers are designed to rotate the pipes while they move through the machine, ensuring uniform blasting.

3.Adjustable Settings:

The machine can be adjusted to accommodate different pipe diameters and lengths. The conveyor speed is typically adjustable (e.g., 1.0-5 m/min), allowing for optimal cleaning based on the specific requirements.

4.High-Quality Construction:

Built with durable materials such as manganese steel liners to protect the blast chamber and ensure long-term performance.

5.Environmental Protection:

Integrated dust collection systems capture and filter the dust generated during the blasting process, minimizing environmental impact.

6.PLC Control System:

The machine is controlled by a PLC (Programmable Logic Controller) system, which allows for precise control of the blasting process and ensures consistent results.

Technical Parameters

1.Cleaning Size:

Diameter range: Typically from 50 mm to 2800 mm.

2.Cleaning Speed:

Conveyor speed: 1.0-5 m/min.

3.Blast Wheels:

Power: 6 x 15 kW (for example).

Abrasive flow rate: Up to 6 x 250 kg/min.

4.Surface Quality:

Surface quality grade: Sa2-Sa2.5 (GB8923-88).

Surface roughness: 15-50 µm (GB1031-83).

Applications

1. Rust and Scale Removal: Effective in removing rust, scale, and other contaminants from steel pipes.

2. Paint Preparation: Prepares the surface for painting or coating by creating a uniform texture.

3. Surface Texturing: Enhances the surface finish, making it suitable for further processing.

Benefits

1. Increased Production Efficiency: The automated process allows for high production rates with minimal manual labor.

2. Improved Surface Quality: Ensures a consistent and high-quality surface finish suitable for further processing.

3. Cost-Effective: Reduces labor costs and minimizes waste through the recycling of abrasive media.

Overall, the Steel Pipe Outer Wall Shot Blasting Machine with Roller Conveyor is an essential tool for industries that require high-quality surface treatment of steel pipes. It offers a combination of efficiency, versatility, and environmental protection, making it a valuable investment for any steel processing facility.