Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

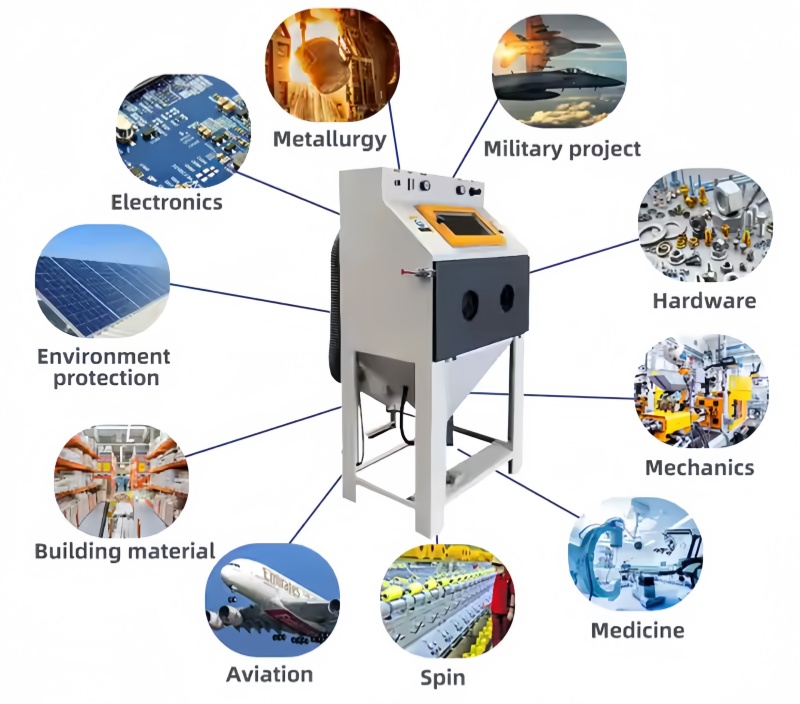

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Small Sand Blaster

2.Model:MS

3.Operation Way: Manual

A small sand blaster is a compact and portable device designed to clean, strip, and prepare surfaces by propelling abrasive materials at high velocity using compressed air. It is commonly used for tasks such as rust removal, paint stripping, and surface roughening.

Uses

1.Small sand blasters are versatile tools suitable for various applications, including:

2.Rust Removal: Quickly and effectively removes rust from metal surfaces.

3.Paint Stripping: Removes multiple layers of paint from various materials.

4.Surface Preparation: Prepares surfaces for painting or coating by creating a rough texture.

5.Glass Etching: Creates designs and patterns on glass surfaces.

6.Home Appliance Maintenance: Cleans and restores small appliances and tools.

Functions

The primary functions of a small sand blaster include:

1.Cleaning: Removes contaminants, rust, and old coatings.

2.Surface Smoothing: Smooths rough surfaces and removes imperfections.

3.Surface Roughening: Increases surface roughness to enhance adhesion of new coatings.

4.Decorative Effects: Etches designs into glass or other materials.

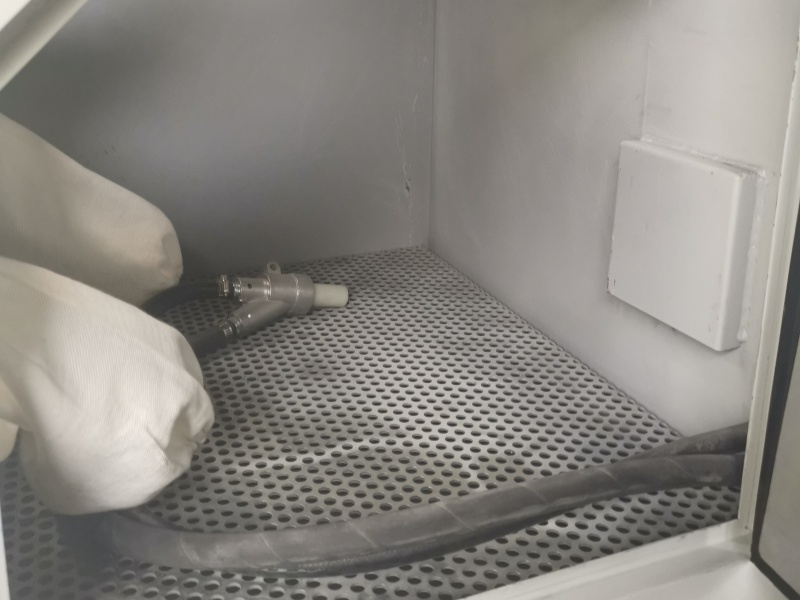

Components

A small sand blaster typically consists of the following key components:

1.Air Compressor: Provides the necessary air pressure to propel the abrasive material.

2.Blast Pot or Reservoir: Holds the abrasive material and feeds it into the airstream.

3.Blast Nozzle: Directs the abrasive stream onto the workpiece.

4.Foot Pedal or Trigger: Controls the flow of the abrasive material.

5.Dust Collector: Captures and filters the dust generated during the process.

6.Safety Gear: Includes protective clothing, gloves, goggles, and a respirator.

Working Principle

The working principle of a small sand blaster involves the following steps:

1.Air Compression: The air compressor generates high-pressure air.

2.Abrasive Delivery: The blast pot or reservoir releases the abrasive material into the airstream.

3.Propulsion: The compressed air propels the abrasive particles at high speed through the blast nozzle.

4.Surface Impact: The abrasive stream impacts the workpiece, removing contaminants and achieving the desired surface effect.

5.Dust Management: The dust collector captures and filters the resulting dust and debris.

Workflow

The typical workflow for using a small sand blaster includes:

1.Preparation: Clean the workpiece and select the appropriate abrasive material.

2.Equipment Setup: Connect the air compressor, blast pot, and nozzle, and adjust the air pressure.

3.Blasting Process: Activate the foot pedal or trigger and move the nozzle across the workpiece surface.

4.Inspection: Check the treated surface for the desired effect and repeat if necessary.

5.Cleanup: Remove any residual abrasive material and clean the workpiece.

How to Choose a Small Sand Blaster

When selecting a small sand blaster, consider the following factors:

1.Type of Sandblaster: Choose between gravity-fed, pressure, and siphon sandblasters based on your specific needs.

2.Air Pressure and Flow: Ensure the sandblaster's PSI (pounds per square inch) and CFM (cubic feet per minute) ratings match your compressor's capabilities.

3.Abrasive Compatibility: Select a sandblaster that supports the type of abrasive material you plan to use.

4.Portability and Size: Consider the size and weight of the sandblaster, especially if you need to move it frequently.

5.Safety Features: Look for models with built-in safety features, such as dust collectors and protective gear.

6.After-Sales Service: Ensure the supplier offers good after-sales service for any maintenance or repair needs.

7.Price: Choose a sandblaster that offers good cost performance for your budget.

By carefully considering these factors, you can choose a small sand blaster that meets your needs and delivers effective results for your projects.