Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Sand blasting machines, also known as abrasive blasting machines, are utilized across various industries for surface preparation, cleaning, and finishing. These machines operate by propelling abrasive materials at high speeds onto a surface to achieve a desired texture, cleanliness, or finish.

Uses of Sand Blasting Machines

1.Surface Preparation:

Sand blasting machines are extensively used for preparing surfaces before painting or coating . The process ensures that the surface is free from contaminants, providing an optimal base for the application of new layers.

Example: In the automotive industry, sand blasting is used to prepare car bodies for repainting by removing old paint and rust.

2.Cleaning:

These machines effectively remove rust, scale, and paint from metal surfaces . They are also used to clean concrete surfaces before sealing or coating.

Example: In construction, sand blasting is used to clean large structures like bridges to remove old paint and prepare the surface for new coatings.

3.Finishing:

Sand blasting provides a uniform finish on surfaces, which can be either decorative or functional . It can create a matte finish on metals or a non-slip surface on floors.

Example: In the manufacturing of kitchen utensils, sand blasting is used to give a smooth, satin finish to stainless steel products.

4.Etching and Engraving:

Sand blasting machines can etch or engrave designs onto glass, stone, or metal surfaces . This is commonly used for creating signs, awards, and personalized items.

Example: In the signage industry, sand blasting is used to create frosted effects on glass or to engrave logos and text on stone or metal plaques.

Working Principle

The working principle of sand blasting machines involves the use of compressed air or a mechanical means to propel abrasive materials onto a surface. There are two main types of sand blasting machines based on their working principle:

1.Air-Powered Sand Blasters:

These machines use compressed air to accelerate abrasive particles through a nozzle, which is directed at the surface to be treated . The force of the abrasive particles removes surface materials or contaminants.

The pressure can be adjusted depending on the material being blasted and the desired effect.

2.Mechanical Sand Blasters (Wheel Abrators):

These machines use a spinning wheel to propel abrasive materials onto the surface . The wheel's centrifugal force accelerates the abrasive particles, which are then directed at the workpiece.

This type is more suitable for heavy-duty applications and can handle larger volumes of abrasive material.

Types of Sand Blasting Machines

1.Suction or Siphon Sand Blasters:

These machines use the venturi effect to draw abrasive materials into a stream of compressed air . They are less aggressive and require higher air pressure to maintain media flow.

Suitable for lighter tasks and short-run production.

2.Pressure Sand Blasters:

These machines use a pressure vessel to hold the abrasive material, which is then forced through a hose and out of a nozzle using compressed air .

They are more aggressive and can handle heavier media, making them suitable for industrial applications.

3.Wet Sand Blasters:

These machines use water mixed with abrasive materials to clean or prepare surfaces . The water acts as a coolant and dust suppressant, making this type suitable for environments where dust control is critical.

4.Vapor Sand Blasters:

Similar to wet sand blasters, vapor sand blasters use a mixture of water, abrasive media, and compressed air . They offer a lower dust generation footprint and can be used for cleaning and degreasing.

5.Portable Sand Blasters:

These are versatile machines that can be moved around different job sites . They are ideal for small-scale projects or when mobility is required.

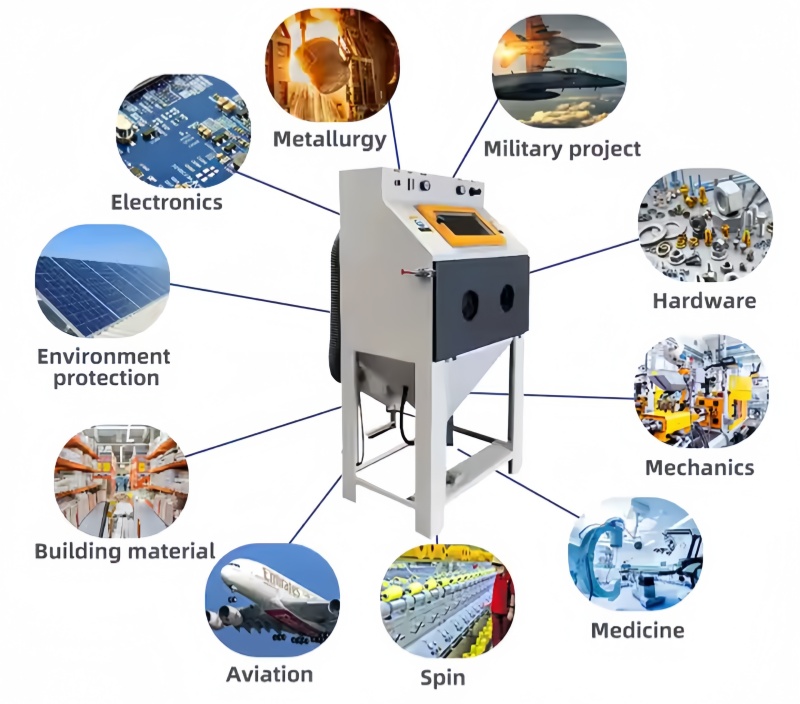

Applications of Sand Blasting Machines

Sand blasting machines are used in a variety of applications across different industries:

1.Automotive Industry:

Used for removing old paint and rust from car bodies, preparing surfaces for new coatings, and cleaning engine parts .

2.Aerospace Industry:

Sand blasting is used for cleaning and preparing aircraft parts, such as turbine blades, and for etching or engraving identification marks .

3.Construction Industry:

Used for cleaning and preparing surfaces of buildings, bridges, and other structures before painting or sealing .

4.Manufacturing:

Sand blasting machines are used for surface preparation before processes like electroplating, painting, and coating to ensure an absolutely clean surface .

5.Marine Industry:

Used for removing rust and old paint from ships and marine structures, as well as for preparing surfaces for new coatings .

6.Metalworking:

Used for deburring, deflashing, and surface preparation of metal parts .

7.Glass and Ceramics:

Sand blasting is used for etching and frosting glass, as well as for surface preparation of ceramic products .

Safety and Environmental Considerations

1.Health Risks:

Sand blasting can generate fine dust, which can be harmful if inhaled . The use of personal protective equipment (PPE) such as respirators, gloves, and protective clothing is essential.

2.Environmental Impact:

The process can produce a significant amount of waste material and dust, which requires proper disposal to avoid environmental contamination . The use of dust collection systems and air filtration systems is crucial.

3.Regulatory Compliance:

Industries must comply with regulations set by bodies like OSHA and EPA regarding worker protection and environmental standards .

4.Sustainable Alternatives:

There is a growing trend towards using environmentally friendly abrasive materials and recycling systems to reduce waste and environmental impact .

Conclusion

Sand blasting machines are indispensable in various industries for their ability to clean, prepare, and finish surfaces effectively. With advancements in technology, these machines have become more efficient, safer, and environmentally friendly. As industries continue to evolve, the role of sand blasting machines in surface treatment processes will remain significant, with ongoing innovations ensuring their relevance in modern manufacturing and industrial applications.