Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Sand blasting equipment, also known as abrasive blasting equipment, is a system used to clean, smooth, or roughen surfaces by propelling abrasive materials at high speed using compressed air. Despite the name, modern sand blasting rarely uses sand due to health risks and inefficiencies; instead, alternatives like steel grit, glass beads, and aluminum oxide are commonly used.

Uses

Sand blasting equipment is widely used across various industries for multiple purposes:

1.Surface Cleaning: It effectively removes rust, paint, and other contaminants from metal surfaces.

2.Surface Preparation: It prepares surfaces for coating or painting by creating a rough texture that enhances adhesion.

3.Restoration: It is used to restore antique items, clean historical monuments, and refurbish old machinery.

4.Etching and Engraving: It can etch designs or text into surfaces for decorative or identification purposes.

5.Deburring and Smoothing: It removes burrs from machined parts and smooths rough edges.

Functions

The primary functions of sand blasting equipment include:

1.Cleaning: Removing surface impurities, oxides, and old coatings.

2.Surface Hardening: Increasing the surface hardness and durability of metal parts.

3.Roughening: Creating a textured surface to improve the adhesion of subsequent coatings.

4.Decorative Effects: Applying a matte finish or specific patterns to surfaces.

Components

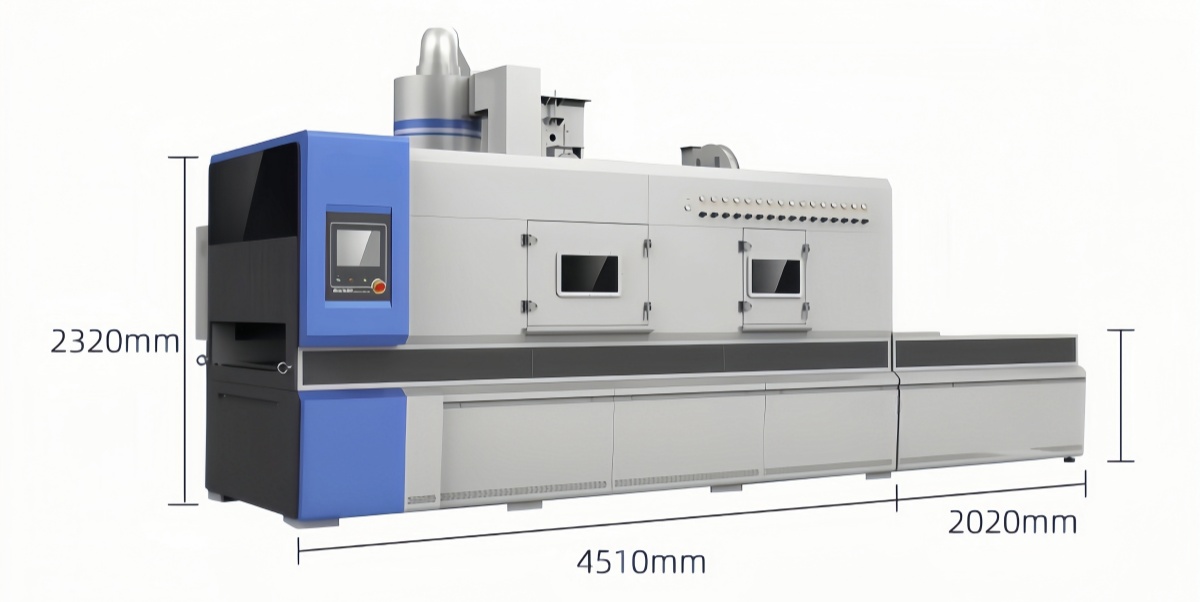

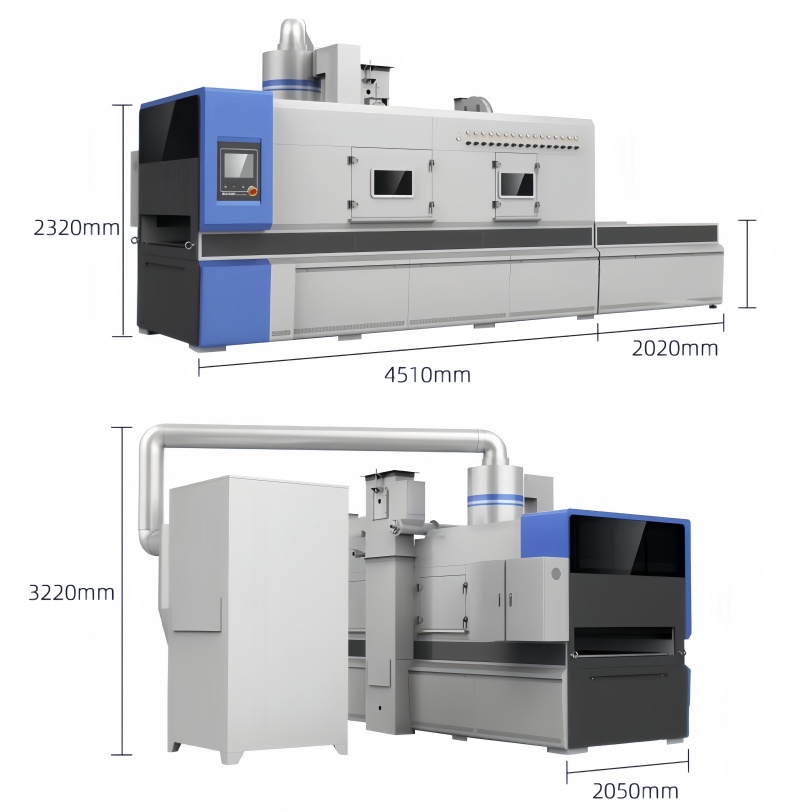

Sand blasting equipment consists of several key components:

1.Air Compressor: Provides the pressurized air needed to propel the abrasive material.

2.Blast Pot: A container that holds the abrasive material and regulates its flow into the airstream.

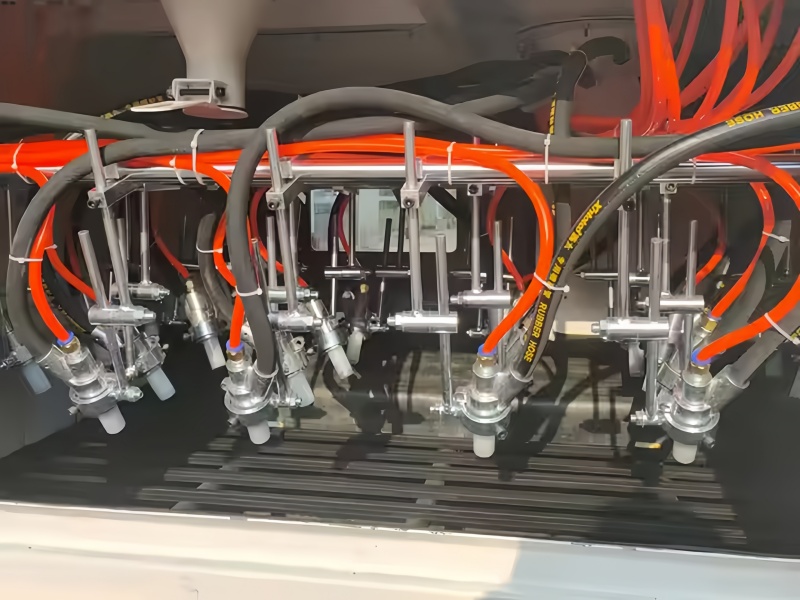

3.Blasting Nozzle: Directs the abrasive stream onto the workpiece, with different nozzle sizes and shapes for various applications.

4.Dust Collection System: Captures and filters the dust and debris generated during the blasting process to maintain a clean environment.

5.Reclamation System: Recovers and recycles used abrasive material, reducing waste and costs.

6.Control Panel: Allows operators to adjust parameters such as pressure, nozzle angle, and media flow rate.

Working Principle

The working principle of sand blasting equipment involves the following steps:

1.Compressed Air Supply: The air compressor generates high-pressure air.

2.Abrasive Delivery: The blast pot releases the abrasive material into the airstream.

3.Propulsion: The compressed air propels the abrasive particles at high speed through the blasting nozzle.

4.Surface Impact: The abrasive stream impacts the workpiece surface, removing contaminants and achieving the desired surface effect.

5.Dust Management: The dust collection system captures and filters the resulting dust and debris.

Workflow

The typical workflow for using sand blasting equipment includes:

1.Preparation: The workpiece is cleaned and positioned, and the appropriate abrasive material is selected.

2.Equipment Setup: The air compressor, blast pot, and nozzle are configured according to the job requirements.

3.Blasting Process: The operator starts the equipment, adjusts the pressure and nozzle angle, and moves the nozzle across the workpiece surface.

4.Inspection: The treated surface is inspected for the desired roughness or cleanliness, and adjustments are made if necessary.

5.Post-Processing: The workpiece is cleaned to remove any residual abrasive material, and the surface is inspected for quality.

Sand blasting equipment is an essential tool in many industries due to its versatility and effectiveness in surface treatment. Proper selection, operation, and maintenance of the equipment are crucial for achieving optimal results and ensuring a safe working environment.