Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Sand blast equipment, also known as abrasive blasting equipment, is a versatile and essential tool used across various industries for surface preparation, cleaning, and finishing. Below is a detailed introduction to sand blast equipment:

Main Components

1.Air Compressor

The air compressor is a crucial part of the sand blasting system. It generates the high-pressure air needed to propel the abrasive media. The capacity and power of the compressor depend on the size and type of sand blaster being used.

2.Blast Pot

The blast pot serves as the reservoir for the abrasive media. It is a pressure vessel that holds the media and regulates its flow into the compressed air stream. Blast pots come in various sizes, ranging from small portable units to large industrial models.

3.Blast Hose

The blast hose is a durable, flexible conduit that carries the mixture of abrasive media and compressed air from the blast pot to the nozzle. It is designed to withstand high pressure and abrasive wear.

4.Blast Nozzle

The nozzle is the final component through which the abrasive media exits. It accelerates the air/abrasive mixture and directs it onto the target surface. Nozzles come in different shapes, sizes, and materials, such as silicon carbide and boron carbide, which offer greater wear resistance.

5.Dust Collector

A dust collector is essential for capturing excess dust and debris generated during the blasting process. It helps maintain a clean and safe working environment.

6.Control Valve

This valve regulates the flow of air and abrasive media, allowing for precise control over the blasting process.

Types of Sand Blast Equipment

1.Pressure Blast Equipment

This type uses compressed air to propel the abrasive media directly from a pressure vessel. It is suitable for heavy-duty applications and provides consistent blasting performance.

2.Suction (Siphon) Blast Equipment

In this system, the abrasive is drawn into the air stream through a vacuum created by compressed air. It is generally less efficient than pressure blasting but is more cost-effective and easier to set up.

3.Wet Blast Equipment

Wet blasting uses water mixed with abrasive media to reduce dust and provide a gentler cleaning action. It is ideal for delicate surfaces and applications where dust control is critical.

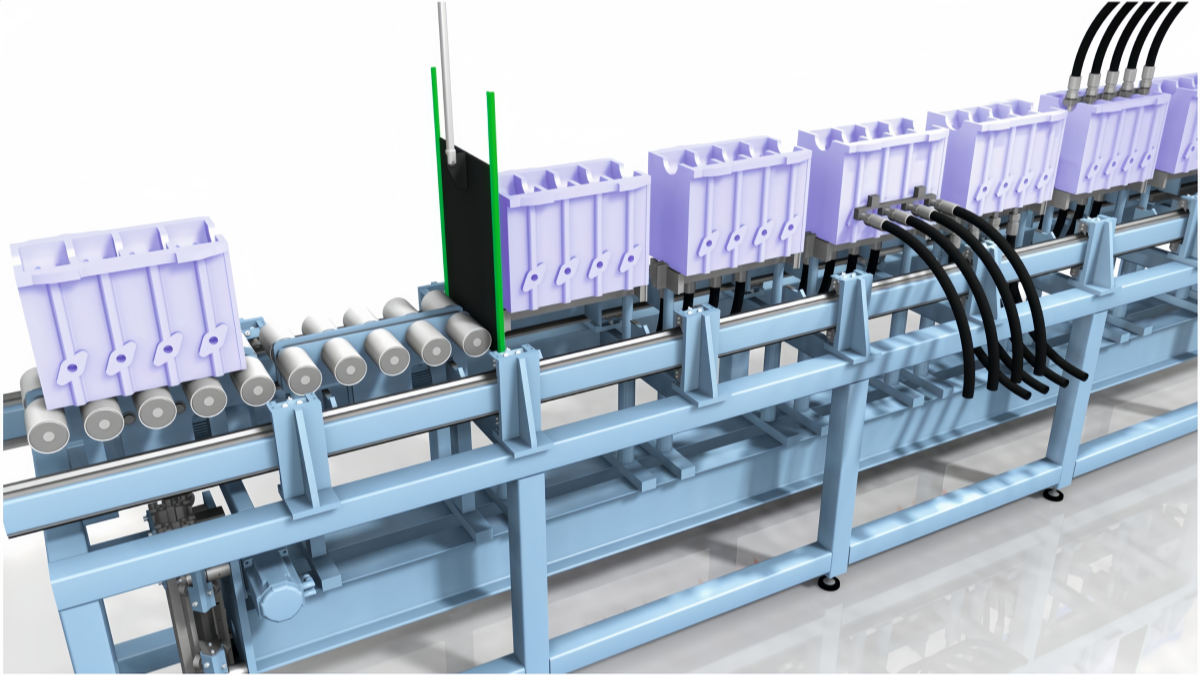

4.Wheel Blast Equipment

This type uses a high-speed wheel to propel the abrasive media. It is highly efficient and often used in automated industrial settings for large-scale surface preparation.

5.Blast Cabinets and Rooms

Blast cabinets are enclosed units designed for blasting smaller objects. They provide controlled environments and minimize dust spread. Blast rooms are larger, enclosed spaces used for cleaning larger structures or objects.

Working Principle

The basic working principle of sand blast equipment involves the following steps:

1.The air compressor generates high-pressure air.

2.The abrasive media is loaded into the blast pot.

3.The compressed air is directed through the blast pot, carrying the abrasive media through the blast hose.

4.The mixture exits through the blast nozzle at high velocity, impacting the target surface to achieve the desired effect.

Applications

Sand blast equipment is used in various industries, including:

1.Automotive and Aerospace: For cleaning and surface preparation of vehicle bodies and aircraft components.

2.Construction: To remove rust, paint, and scale from steel structures.

3.Manufacturing: For deburring, shot peening, and improving surface finishes.

4.Restoration: For cleaning and restoring historic buildings and monuments.

Advantages and Disadvantages

Advantages:

1.Rapid cleaning of large surfaces.

2.Less labor-intensive compared to manual methods.

3.Potential for automation and consistent results.

Disadvantages:

1.High noise and dust levels.

2.Potential environmental impact from certain abrasive media.

3.Risk of equipment wear and operator injury if safety measures are not followed.

In summary, sand blast equipment is a powerful and versatile tool that plays a vital role in many industrial processes. Its effectiveness and adaptability make it an essential component in surface preparation and finishing operations.