Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

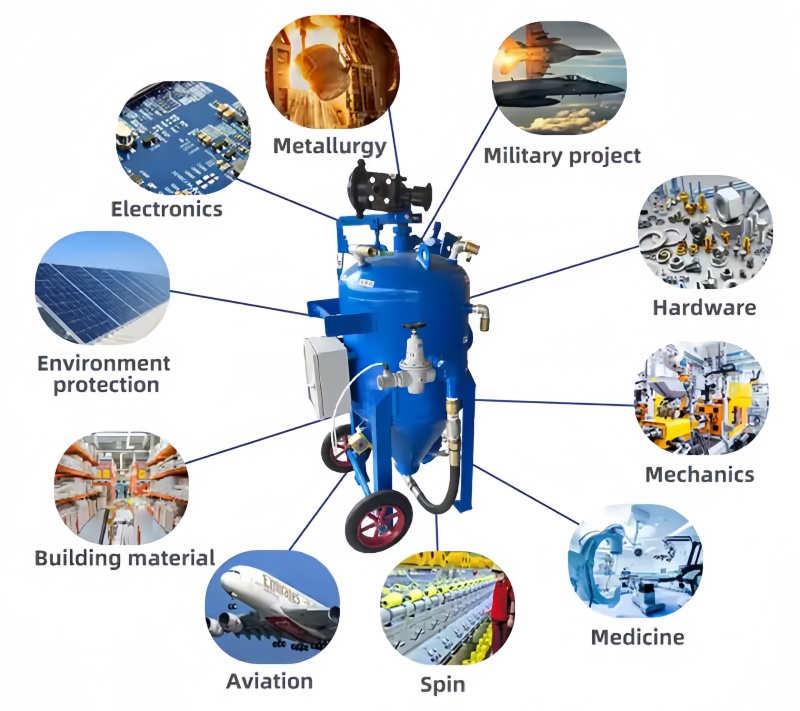

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Uses

Mini sand blasters are compact and portable devices designed for a variety of surface treatment applications. They use compressed air to propel abrasive materials at high speed onto a surface to achieve the desired effect. Here are some of the primary uses:

1.Surface Cleaning:

Mini sand blasters are used to remove rust, paint, and other contaminants from metal surfaces. For example, they can be used to clean car bodies before painting to ensure a smooth and durable finish.

They are also effective in removing residual stress and improving the surface hardness of materials, which enhances the durability of the treated surfaces.

2.Surface Preparation:

These machines prepare surfaces for painting or coating by creating a rough texture that increases the adhesion of new coatings. This is crucial in industries like automotive and aerospace, where high-quality surface preparation is necessary for the longevity and performance of coatings.

They are also used for etching and engraving on surfaces like glass, crystal, jade, marble, and ceramics.

3.Rust Removal:

Mini sand blasters are highly effective in removing rust from metal surfaces, achieving high cleaning standards (up to Sa3 grade). This is particularly important in the maintenance of tools and machinery.

4.Paint Stripping:

They are used to remove multiple layers of paint from various materials, making them ideal for automotive repair shops and industrial maintenance.

5.Delicate Jobs and Hobbyist Use:

Mini sand blasters are ideal for smaller blasting jobs and hobbyist-level blasting. They are also suitable for restoration works that require low pressure and precision, such as tombstones.

Functions

1.Cleaning and Stripping:

The primary function is to clean and strip surfaces by removing contaminants and old coatings. This is achieved through the high-velocity impact of abrasive materials, which effectively dislodge impurities.

2.Surface Roughening:

They can alter the surface roughness (Ra value) of materials, which is important for achieving the desired texture for subsequent processes.

3.Pre-Treatment for Coating:

Mini sand blasters provide an active surface that enhances the adhesion of coatings, whether for painting, plating, or other surface treatments.

4.Precision Parts Finishing:

They are capable of high-precision and complex-shaped parts finishing, which is difficult to achieve with other methods. This is particularly useful in the manufacturing of precision instruments and aerospace components.

5.Improving Surface Properties:

These machines can change the surface stress state and improve the lubrication conditions of mating parts, reducing noise during operation.

Main Features

1.Portability:

Mini sand blasters are designed to be lightweight and easy to transport, making them suitable for on-site work and various locations.

2.Versatility:

They can handle different types of abrasive media, allowing them to tackle a wide range of tasks. They can be used with sand, glass beads, baking soda, and other media.

3.Ease of Use:

Mini sand blasters are user-friendly, with adjustable air pressure and media flow to suit different applications. Some models come with a user-friendly pneumatic valve for air inlet and a discharge diaphragm valve.

4.Safety:

Many models come with safety features such as dust collection systems to protect the user from harmful particles. Some models include an operator’s system that includes a filter for hood’s supply.

5.Economic Efficiency:

They are designed for economic efficiency, with features like recyclable abrasive materials and long-lasting components. This reduces operational costs and extends the lifespan of the equipment.

Applicable Scenarios

1.Automotive Repair Shops:

In automotive repair shops, mini sand blasters are used for cleaning car parts, removing rust and old paint layers before applying new coatings. They are also used for precision parts finishing and surface preparation for high-quality paint jobs.

2.Hobbyists and DIY Enthusiasts:

For hobbyists and DIY enthusiasts, mini sand blasters are ideal for smaller projects such as model building, furniture refinishing, and artwork. They provide the necessary precision and control for detailed work.

3.Restoration Projects:

In restoration projects, mini sand blasters are used for cleaning and restoring antiques, sculptures, and architectural elements. They can be calibrated to preserve intricate detail while removing grime and debris.

4.Industrial Maintenance:

In industrial settings, mini sand blasters are used for maintenance tasks such as cleaning machinery, removing rust from equipment, and preparing surfaces for recoating.

5.Educational Institutions:

In educational settings, mini sand blasters are used for teaching purposes, allowing students to learn about surface treatment processes and gain hands-on experience with industrial equipment.

6.Art and Craft Applications:

Artists and craftsmen use mini sand blasters for creating designs on glass, wood, and other materials. They offer precise control and the ability to achieve various surface effects.

7.Jewelry Making:

In jewelry making, mini sand blasters are used for surface finishing and polishing of small, delicate pieces. They provide the precision needed to achieve a high-quality finish without damaging the materials.

8.Electronic Component Manufacturing:

In the electronics industry, mini sand blasters are used for cleaning and preparing surfaces of electronic components. They ensure the cleanliness and precision required for high-quality electronic devices.

Examples of Mini Sand Blasters

1.MZ-100 Mini Sand Blaster:

Capacity: 10 gallons.

Applications: Suitable for removing metal mill scale, surface dirt of metal or non-metal items, etching processing for glass and ceramics, and pre-treatment for various coatings.

Features: Easy operation, high safety, low processing cost.

2.Miniblast Portable Sandblaster:

Tank Capacity: 15 liters.

Features: Professional handy and portable, designed for restoration works, comes with a 3mm nozzle lance and an additional 2mm micro-nozzle for small touch-up works.

Optional Features: Can be equipped with a vacuum recovery system for dust-free operation.

3.MIZHI Sandblaster - Miniblast R:

Tank Capacity: 15 liters.

Features: Portable, easy to use, light sandblaster designed for on-site works.

Included Equipment: Brush head with 4mm nozzle, remote control handle, 1100 W vacuum, 4 meters suction hose, and sand blast hose.

Conclusion

Mini sand blasters are versatile and essential tools for a wide range of applications, from automotive repair to artistic endeavors. Their compact size, ease of use, and ability to handle various abrasive media make them suitable for both professionals and hobbyists. By choosing the right mini sand blaster and abrasive media, users can achieve high-quality surface treatments efficiently and safely.

Model | Capacity (CF) | Continuous Time(min) | External Dimensions(mm) | Weight (kg) | Pressure (Psi) |

MZ-150 | 1 | 15 | H1240x800x900 | 120 | 30-150 |

MZ-225 | 2 | 30 | H1400x760x910 | 140 | 30-150 |

MZ-500 | 5 | 60 | H1560x1000x1080 | 220 | 30-150 |

MZ-800 | 8 | 90-120 | H1800x1000x1080 | 240 | 30-150 |

Machine including | |||||

1) 15m sandblasting hose:1pc 2) Boron carbide nozzle:1 pc 3) Pipe-clamping valve:1pc 4) Feeding hopper:1pc 5) Vibrator:1pc 6) Pressure regulating valve:1pc 7) Pressure reducing valve:1pc | |||||