Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Industrial Sand Blaster

2.Model:MZ

3.Operation Way: Manual

Industrial sandblasting machines are essential equipment in various manufacturing and surface treatment processes. They are designed to clean, strip, and prepare surfaces by propelling abrasive materials at high velocity using compressed air. Here is a detailed introduction to their uses, functions, main features, and applications across different industrial scenarios.

Uses of Industrial Sandblasting Machines

1.Surface Cleaning:

Industrial sandblasting machines are used to remove rust, paint, and other contaminants from metal surfaces. For example, in the automotive industry, they are used to clean car bodies before painting to ensure a smooth and durable finish.

They are also effective in removing residual stress and improving the surface hardness of materials, which enhances the durability of the treated surfaces.

2.Surface Preparation:

These machines prepare surfaces for painting or coating by creating a rough texture that increases the adhesion of new coatings. This is crucial in industries like aerospace, where high-quality surface preparation is necessary for the longevity and performance of coatings.

3.Rust Removal:

They are highly effective in removing rust from metal surfaces, achieving high cleaning standards (up to Sa3 grade). This is particularly important in the shipbuilding industry, where large metal structures are prone to rust due to exposure to seawater.

4.Paint Stripping:

Industrial sandblasters are used to remove multiple layers of paint from various materials, making them ideal for automotive repair shops and industrial maintenance.

5.Old Machinery Renovation:

These machines are suitable for the renovation of old machinery, restoring surfaces to a like-new condition. This is common in industries where equipment needs to be refurbished to extend its service life.

Functions of Industrial Sandblasting Machines

1.Cleaning and Stripping:

The primary function is to clean and strip surfaces by removing contaminants and old coatings. This is achieved through the high-velocity impact of abrasive materials, which effectively dislodge impurities.

2.Surface Roughening:

They can alter the surface roughness (Ra value) of materials, which is important for achieving the desired texture for subsequent processes.

3.Pre-Treatment for Coating:

Industrial sandblasting machines provide an active surface that enhances the adhesion of coatings, whether for painting, plating, or other surface treatments.

4.Precision Parts Finishing:

They are capable of high-precision and complex-shaped parts finishing, which is difficult to achieve with other methods. This is particularly useful in the manufacturing of precision instruments and aerospace components.

5.Improving Surface Properties:

These machines can change the surface stress state and improve the lubrication conditions of mating parts, reducing noise during operation.

Main Features of Industrial Sandblasting Machines

1.Dust Control:

Industrial sandblasting machines, especially liquid types, effectively control dust pollution, improving the working environment. For example, the SS-1C model from Beijing Changkong uses a combination of water and abrasive to minimize dust.

2.Versatility:

These machines are highly versatile, capable of handling different materials and achieving various surface effects. They can be adjusted to suit different processing requirements, making them suitable for a wide range of applications.

3.High Surface Quality:

The processed surfaces exhibit high quality, with a reduction in roughness values after treatment. This is due to the precise control of abrasive materials and processing parameters.

4.Economic Efficiency:

The machines are designed for economic efficiency, with features like recyclable abrasive materials and long-lasting components. This reduces operational costs and extends the lifespan of the equipment.

5.Safety and Environmental Compliance:

Modern industrial sandblasting machines come with safety and environmental features, such as enclosed systems and efficient dust collection, ensuring compliance with regulations.

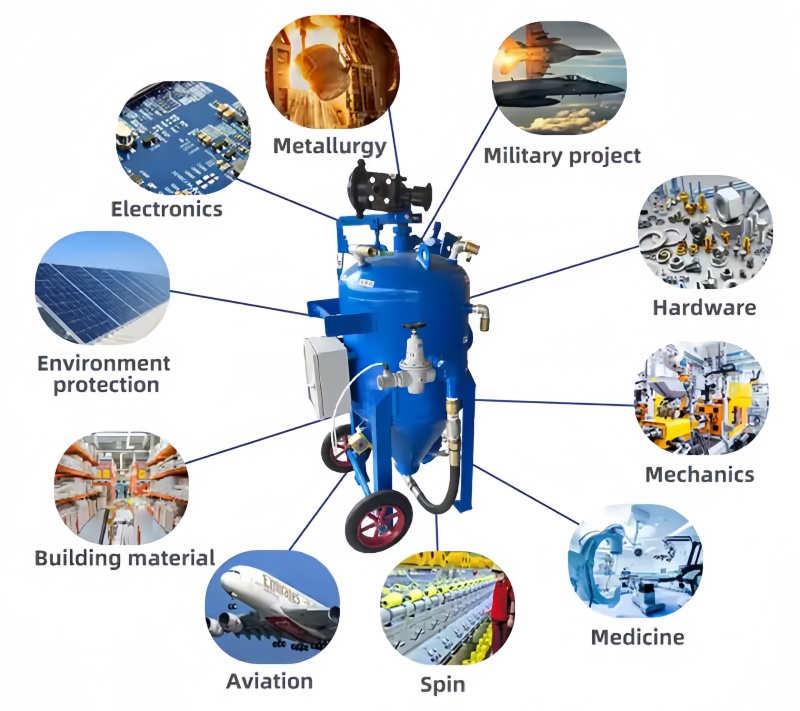

Applications in Different Industrial Scenarios

1.Automotive Industry:

In the automotive industry, sandblasting machines are used for cleaning car bodies, removing rust and old paint layers before applying new coatings. They are also used for precision parts finishing and surface preparation for high-quality paint jobs.

2.Aerospace Industry:

In aerospace manufacturing, conveyor-type automatic sandblasting machines are used for high-precision and high-efficiency surface treatment of aircraft components. These machines ensure uniform spray quality and reduce human error, meeting the high standards of the industry.

3.Shipbuilding Industry:

In shipbuilding, sandblasting machines are essential for rust removal and surface preparation of large metal structures. They are used to clean and prepare the hulls of ships for painting, ensuring durability and longevity.

4.Construction Industry:

In construction, sandblasting machines are used for surface preparation of building materials and structures. They are also used for removing old coatings and contaminants from concrete surfaces.

5.Medical Equipment Manufacturing:

In the medical field, sandblasting machines are used for surface treatment of medical devices and equipment, ensuring cleanliness and precision. They are particularly useful for preparing surfaces for sterilization and coating.

6.Food Processing Equipment:

In food processing, sandblasting machines are used for cleaning and preparing surfaces of equipment that comes into contact with food products. They ensure hygiene and safety by removing contaminants and old coatings.

7.Chemical Equipment Manufacturing:

In chemical manufacturing, sandblasting machines are used for surface treatment of chemical reactors and storage tanks. They ensure the durability and longevity of equipment by removing rust and contaminants.

8.Mold Manufacturing:

In mold manufacturing, sandblasting machines are used for surface treatment of molds to improve their lifespan and performance. They ensure uniformity and precision in mold finishing, which is crucial for high-quality molding.

9.Metalworking Industry:

In metalworking, sandblasting machines are used for surface preparation and rust removal from metal parts. They ensure the quality and durability of metal components by providing a clean and smooth surface for further processing.

In conclusion, industrial sandblasting machines are indispensable tools in various industries due to their versatility, efficiency, and ability to provide high-quality surface treatments. Their applications range from automotive and aerospace to construction and food processing, making them a crucial part of modern manufacturing processes.

Model | Capacity (CF) | Continuous Time(min) | External Dimensions(mm) | Weight (kg) | Pressure (Psi) |

MZ-150 | 1 | 15 | H1240x800x900 | 120 | 30-150 |

MZ-225 | 2 | 30 | H1400x760x910 | 140 | 30-150 |

MZ-500 | 5 | 60 | H1560x1000x1080 | 220 | 30-150 |

MZ-800 | 8 | 90-120 | H1800x1000x1080 | 240 | 30-150 |

Machine including | |||||

1) 15m sandblasting hose:1pc 2) Boron carbide nozzle:1 pc 3) Pipe-clamping valve:1pc 4) Feeding hopper:1pc 5) Vibrator:1pc 6) Pressure regulating valve:1pc 7) Pressure reducing valve:1pc | |||||