Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Dustless Sandblasting Equipment

2.Model:MZ

3.Operation Way: Manual

Introduction to Dustless Sandblasting Equipment

Dustless sandblasting equipment is a specialized type of surface preparation machinery designed to clean, strip, and prepare surfaces without generating harmful dust. This is achieved through the use of compressed air to propel abrasive materials at high speed, while simultaneously capturing and separating the dust and abrasive particles. This equipment is widely used in industries such as automotive, construction, and metal fabrication for its efficiency, safety, and environmental benefits.

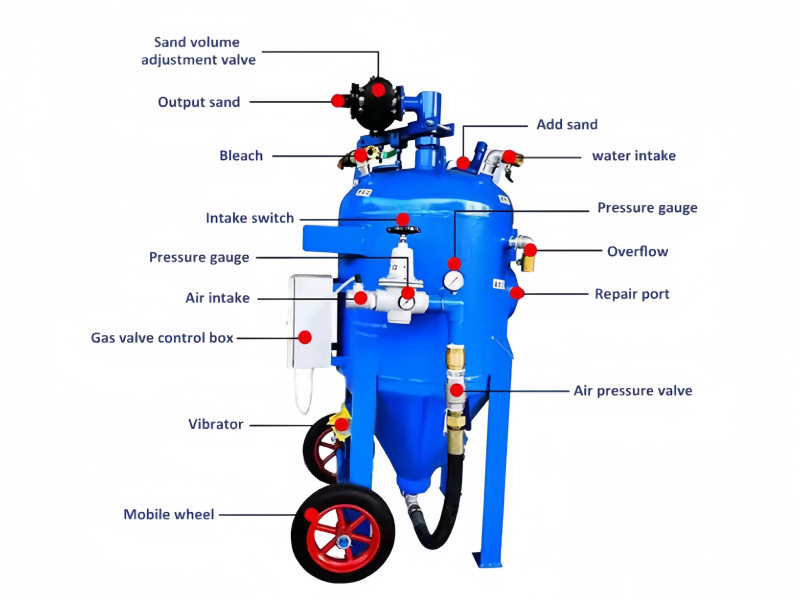

Key Components of Dustless Sandblasting Equipment

1.Blast Pot

The blast pot is the container that holds the abrasive material. It is designed to withstand high pressure and is typically made of durable materials like steel. The MZ150 Abrasive Blaster, for example, has a 1 cubic foot capacity and can hold 50 lbs of abrasive per fill.

The blast pot is connected to an air compressor, which provides the necessary pressure to propel the abrasive material.

2.Air Compressor

The air compressor is essential for providing the high-pressure air required to operate the sandblaster. The MZ150 requires at least a 60 CFM compressor to function effectively.

The compressor's capacity must match the blast pot's requirements to ensure optimal performance.

3.Blast Nozzle

The blast nozzle directs the abrasive stream onto the surface to be treated. It is typically made of tungsten carbide or other durable materials to withstand the abrasive impact.

The nozzle's size and shape can be adjusted depending on the specific application and the desired surface effect.

4.Dust Collection System

The dust collection system is a critical component that captures and separates the dust and abrasive particles from the air. This system ensures a clean work environment and reduces the risk of dust inhalation.Some dustless sandblasters, like the MZ150, can be paired with an air drying and cooling system to enhance dust management.

5.Water System (for Wet Blasting)

For wet blasting applications, the equipment includes a water system that mixes water with the abrasive material. This reduces dust generation and cools the surface being treated.

The MZ150 can hold up to 5 gallons of water per fill, allowing for continuous operation for approximately 15 minutes.

Working Principle

The working principle of dustless sandblasting equipment involves the following steps:

1.Loading the Blast Pot: The abrasive material is loaded into the blast pot, which is then sealed to maintain pressure.

2.Connecting the Air Compressor: The blast pot is connected to an air compressor, which provides the necessary pressure to propel the abrasive material.

3.Initiating the Blast: The operator activates the blast nozzle, which directs the high-pressure abrasive stream onto the surface to be treated.

4.Dust and Particle Separation: The dust collection system captures the dust and abrasive particles, separating them from the air to maintain a clean work environment.

5.Surface Treatment: The abrasive stream impacts the surface, removing contaminants and achieving the desired surface texture.

Advantages of Dustless Sandblasting

1.Environmental Benefits: Dustless sandblasting significantly reduces dust pollution, making it an environmentally friendly option for surface preparation.

2.Health and Safety: By minimizing dust exposure, this equipment reduces the risk of respiratory issues and other health hazards associated with traditional sandblasting.

3.Versatility: Dustless sandblasters can be used for both wet and dry blasting, offering flexibility for different applications.

4.Efficiency: The equipment is designed for continuous operation, with some models like the MZ150 providing up to 15 minutes of continuous run time per fill.

5.Cost-Effective: The recycling of abrasive material reduces waste and operational costs, making dustless sandblasting a cost-effective solution.

Recommended Models

1.MZ150 Abrasive Blaster

Capacity: 1 cubic foot, holds 50 lbs of abrasive per fill.

Water Capacity: Up to 5 gallons for wet blasting.

Operating Pressure: 30-150 PSI.

Dimensions: 48" H x 20" W x 22" D.

Weight: 158 lbs.

Features: Lifetime warranty, made in the USA, and designed for high industry standards.

2.MZ225 and MZ500 Series

These models offer larger capacities and are suitable for more extensive projects. They come with various configurations, including mobile units for on-site applications.

3.MZ800 and MZ1500 Models

These are designed for heavy-duty industrial applications, with larger capacities and more powerful compressors. They are ideal for large-scale projects and industrial maintenance.

How to Choose the Right Dustless Sandblaster

When selecting a dustless sandblaster, consider the following factors:

1.Project Size and Scope: Choose a model that matches the scale of your project. For small to medium-sized projects, the MZ150 is a suitable option.

2.Abrasive Material: Ensure the sandblaster is compatible with the type of abrasive material you plan to use. Some models are designed for specific types of abrasives.

3.Portability: Consider whether you need a mobile unit for on-site applications or a stationary unit for fixed locations.

4.Budget: Dustless sandblasters vary in price, so choose a model that fits within your budget while meeting your project requirements.

5.Maintenance and Support: Look for a brand that offers comprehensive support, including warranties, parts availability, and training.

Conclusion

Dustless sandblasting equipment offers a safe, efficient, and environmentally friendly solution for surface preparation. By considering the specific requirements of your project and choosing the right model, you can achieve high-quality results while minimizing dust pollution and operational costs. Whether you are a professional contractor or a DIY enthusiast, there is a dustless sandblaster that can meet your needs.

Model | Capacity (CF) | Continuous Time(min) | External Dimensions(mm) | Weight (kg) | Pressure (Psi) |

MZ-150 | 1 | 15 | H1240x800x900 | 120 | 30-150 |

MZ-225 | 2 | 30 | H1400x760x910 | 140 | 30-150 |

MZ-500 | 5 | 60 | H1560x1000x1080 | 220 | 30-150 |

MZ-800 | 8 | 90-120 | H1800x1000x1080 | 240 | 30-150 |

Machine including | |||||

1) 15m sandblasting hose:1pc 2) Boron carbide nozzle:1 pc 3) Pipe-clamping valve:1pc 4) Feeding hopper:1pc 5) Vibrator:1pc 6) Pressure regulating valve:1pc 7) Pressure reducing valve:1pc | |||||