Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

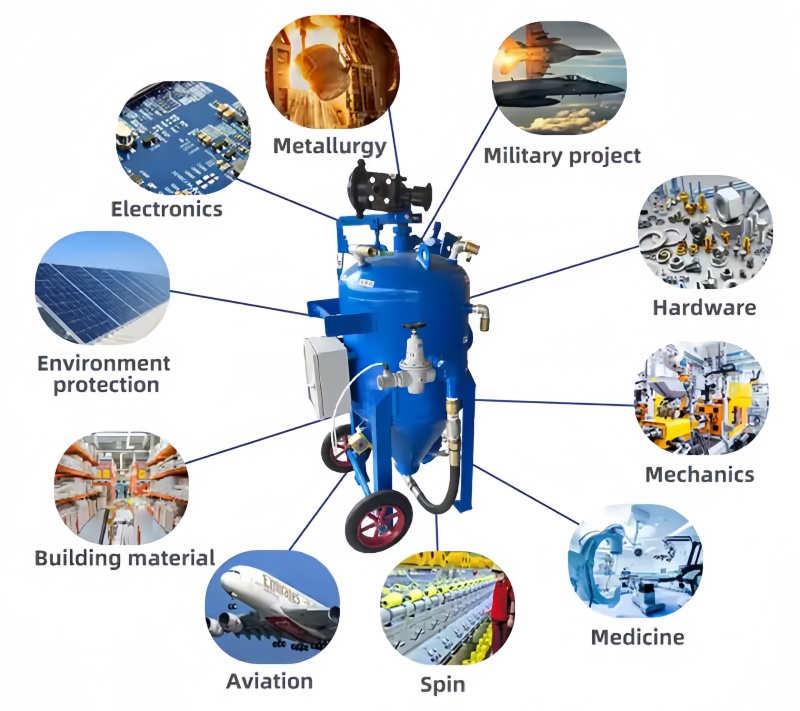

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

1.Name:Dustless Dustless Sand Blaster

2.Model:MZ

3.Operation Way: Manual

A dustless sandblaster is a type of surface treatment equipment designed to clean, strip, and prepare surfaces without generating dust pollution. It uses compressed air to propel abrasive materials at high speed, impacting the surface to be treated. The key feature of a dustless sandblaster is its integrated dust collection and recycling system, which captures and separates the abrasive material from the dust, ensuring a clean and environmentally friendly work environment.

Main Uses

Dustless sandblasters are widely used across various industries for the following purposes:

1.Surface Cleaning: Removing rust, paint, and other contaminants from metal surfaces.

2.Surface Preparation: Preparing surfaces for painting or coating by creating a rough texture that enhances adhesion.

3.Rust Removal: Quickly and effectively removing rust from metal surfaces, achieving high cleaning quality (up to Sa3 grade).

4.Paint Stripping: Removing multiple layers of paint from various materials.

5.Old Machinery Renovation: Suitable for the renovation of old machinery, restoring surfaces to a like-new condition.

6.Precision Parts Finishing: Used for the finishing of high-precision and complex-shaped parts that are difficult to process by other methods.

Advantages

1.Environmental Protection: Improves environmental conditions by reducing dust pollution and protecting workers' health.

2.Economic Efficiency: The abrasive material is recycled, reducing waste and operational costs.

3.Compact Design: The compact structure design reduces energy consumption and lowers operating costs.

4.Ease of Operation: Equipped with a remote control system for convenient operation.

5.High Surface Treatment Quality: Achieves a high surface treatment grade of Sa2.5-3.

Applicable Scenarios

Dustless sandblasters are suitable for a wide range of applications, including:

1.Metal Structures: Ideal for the pre-treatment of steel structures before painting.

2.Shipbuilding and Repair: Effective for removing rust and contaminants from ship hulls and components.

3.Petrochemical Industry: Used for cleaning and preparing surfaces of pipelines and storage tanks.

4.Bridge Construction: Suitable for the surface treatment of bridge steel components.

5.Glass and Stone Processing: Used for surface etching and decorative processing of glass and stone.

Recommended Dustless Sandblaster Models

1. MZ-800 Dustless Sandblaster

Features: This model is designed for high-efficiency surface treatment. It features a large capacity blast pot, a powerful air compressor, and an advanced dust collection system. It is capable of handling a wide range of abrasive materials and is suitable for heavy-duty industrial applications.

Applicable Situations: Ideal for large-scale industrial projects, shipbuilding, and metal structure pre-treatment.

2. MZ-500 Dustless Sandblaster

Features: This model is known for its compact design and ease of use. It is equipped with a cyclone dust collector that effectively separates dust from the abrasive material, ensuring a clean work environment. It is suitable for both indoor and outdoor use.

Applicable Situations: Suitable for medium-sized projects, automotive repair shops, and general maintenance work.

3. MZ-225 Dustless Recycling Sandblaster

Features: This model is an environmentally friendly, mobile sandblasting unit. It features a vacuum system for dust and abrasive material recovery, ensuring a dust-free work environment. It has a large working radius and high efficiency, making it suitable for various industrial applications.

Applicable Situations: Ideal for outdoor construction sites, shipyards, and large-scale industrial maintenance.

4. MZ-150 Dustless Sandblaster

Features: This model is designed for low-dust emission and high cleaning efficiency. It can capture up to 97% of the spray dust emissions, ensuring a clean and safe working environment. It is suitable for various industries, including aerospace, bridges, and marine applications.

Applicable Situations: Suitable for high-standard cleaning requirements in aerospace, bridge maintenance, and marine engineering.

5. MZ-225 Dustless Wet Sandblaster

Features: This model uses a water and abrasive mixture to reduce dust and improve surface cleaning efficiency. It is designed for wet sandblasting, which is less dusty and more environmentally friendly.

It is suitable for various materials, including glass and metal.

Applicable Situations: Ideal for glass and stone surface treatment, automotive repair, and general surface cleaning.

When selecting a dustless sandblaster, consider the specific requirements of your project, such as the size of the workpieces, the type of surface treatment needed, and the environmental conditions of the work site. Each of the recommended models has unique features that make them suitable for different applications, ensuring efficient and environmentally friendly surface treatment.

Model | Capacity (CF) | Continuous Time(min) | External Dimensions(mm) | Weight (kg) | Pressure (Psi) |

MZ-150 | 1 | 15 | H1240x800x900 | 120 | 30-150 |

MZ-225 | 2 | 30 | H1400x760x910 | 140 | 30-150 |

MZ-500 | 5 | 60 | H1560x1000x1080 | 220 | 30-150 |

MZ-800 | 8 | 90-120 | H1800x1000x1080 | 240 | 30-150 |

Machine including | |||||

1) 15m sandblasting hose:1pc 2) Boron carbide nozzle:1 pc 3) Pipe-clamping valve:1pc 4) Feeding hopper:1pc 5) Vibrator:1pc 6) Pressure regulating valve:1pc 7) Pressure reducing valve:1pc | |||||