Hotline

+86-136 8495 9862

Email:cennia@szmizhi.com

Add::104,Building 27,Third Industrial Zone, Longxi Community,Longgang District,Shenzhen,China.

Coil Forming & Handling Equipment

Surface Treatment Equipment

Solutions

Application

About Us

Welcome to MIZHI

For consultation/feedback, please call the service hotline: +86-136 8495 9862 Email:cennia@szmizhi.com

Steel shot recycling machines

Steel shot, as a commonly used abrasive material in industries such as metalworking, automotive, and construction, is highly effective in removing rust, paint, and other surface contaminants from metal surfaces. However, during its use, steel shot gradually wears down and becomes contaminated with debris and impurities. Recycling steel shot can reduce waste, save costs, conserve resources, and minimize environmental impact.

Below is an introduction to steel shot recycling machines:

Working Principle

Steel shot recycling machines primarily utilize magnetic separation, air classification, and screening technologies to separate usable steel shot from waste materials. Magnetic separation uses magnets to attract steel shot, separating it from other non-magnetic substances. Air classification leverages the principle of differential airflow resistance to separate steel shot of different particle sizes and densities. Screening involves passing steel shot through screens or sieves to remove larger debris and contaminants, retaining smaller steel shot particles for reuse.

Types and Features

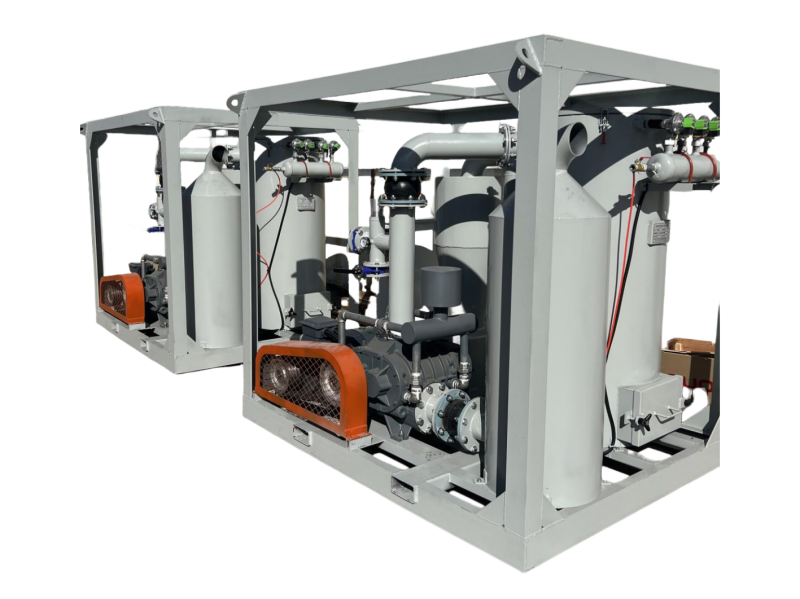

1.ARS Steel Grit Recycling System: ARS’s patented portable steel grit recycling system features superior quality and reliability. Its patented cleaning process sets industry standards for grit cleanliness. By recycling steel grit, it eliminates the need for single-use mineral alternatives, drastically reducing waste disposal costs and overhead expenses. The system is suitable for various project sizes, including standard, compact, and tandem systems.

2.MES 6-Man Steel Grit Recycling Machine: Available in diesel and electric options, this system offers unparalleled performance and is trailer-mounted. It includes a patented cleaning system, 6 auto-fill blast pots, 6-8 nozzles, onboard vacuum, dryers,, classifiers and blast pots, with a storage capacity of over 60 barrels.

3.VB1200 Steel Grit Recycler: Equipped with a dual outlet and fully automatic control system, it efficiently removes coatings, eliminates corrosion, and more.

Wisdom Environmental’s Recycling Equipment: Wisdom Environmental provides iron-based shot dust recycling services, reusing shot dust in innovative SteelCrete products like commercial bins/blocks. Its steel shot recycling process involves collecting spent and undersized steel shot from shot peening and surface preparation operations, transporting it to recycling facilities, cleaning it, screening it to meet SAE J444 specifications for shot and grit screenings, and then repackaging, labeling, and selling it at a significant discount compared to virgin materials.

Advantages

1.Cost Reduction: Using recycled steel shot eliminates the need to purchase new shot frequently, saving on material costs. Additionally, it reduces waste disposal expenses, as waste steel shot can be recycled instead of being discarded as hazardous waste.

2.Environmental Benefits: Recycling steel shot reduces the demand for new resources, lowering the environmental impact of mining and manufacturing new steel shot. It also decreases the amount of waste sent to landfills, minimizing environmental pollution.

3.Quality Assurance: If properly processed and meeting quality standards, recycled steel shot can perform comparably to new shot, ensuring the effectiveness of industrial processes.

4.Resource Conservation: Steel is derived from non-renewable iron ore. By recycling steel shot, industries can reduce the demand for new steel production, conserving natural resources and lowering the environmental footprint of mining and processing activities.

Application Scenarios

Steel shot recycling machines are widely used in industries such as metalworking, automotive manufacturing, and construction. For example, in the automotive industry, they are applied in processes like shot peening of car parts and surface preparation before painting. In metalworking, they are used for rust removal and surface cleaning of metal components. In construction, they assist in the surface treatment of steel structures.

Development Trends

With increasing environmental awareness and rising resource costs, the demand for steel shot recycling machines is growing. Future development trends may include higher automation and intelligence levels, improved recycling efficiency and quality, and greater integration with other environmental protection technologies to achieve more sustainable industrial production.

In summary, steel shot recycling machines play a significant role in reducing costs, conserving resources, and protecting the environment. As technology continues to advance, these machines will become more efficient and intelligent, providing stronger support for sustainable industrial development.